A flexible pressure detection device

A detection device and pressure technology, applied in the direction of hydraulic/pneumatic measurement, etc., can solve the problem of difficult to accurately measure the size of the force, and achieve the effect of strong shape plasticity and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

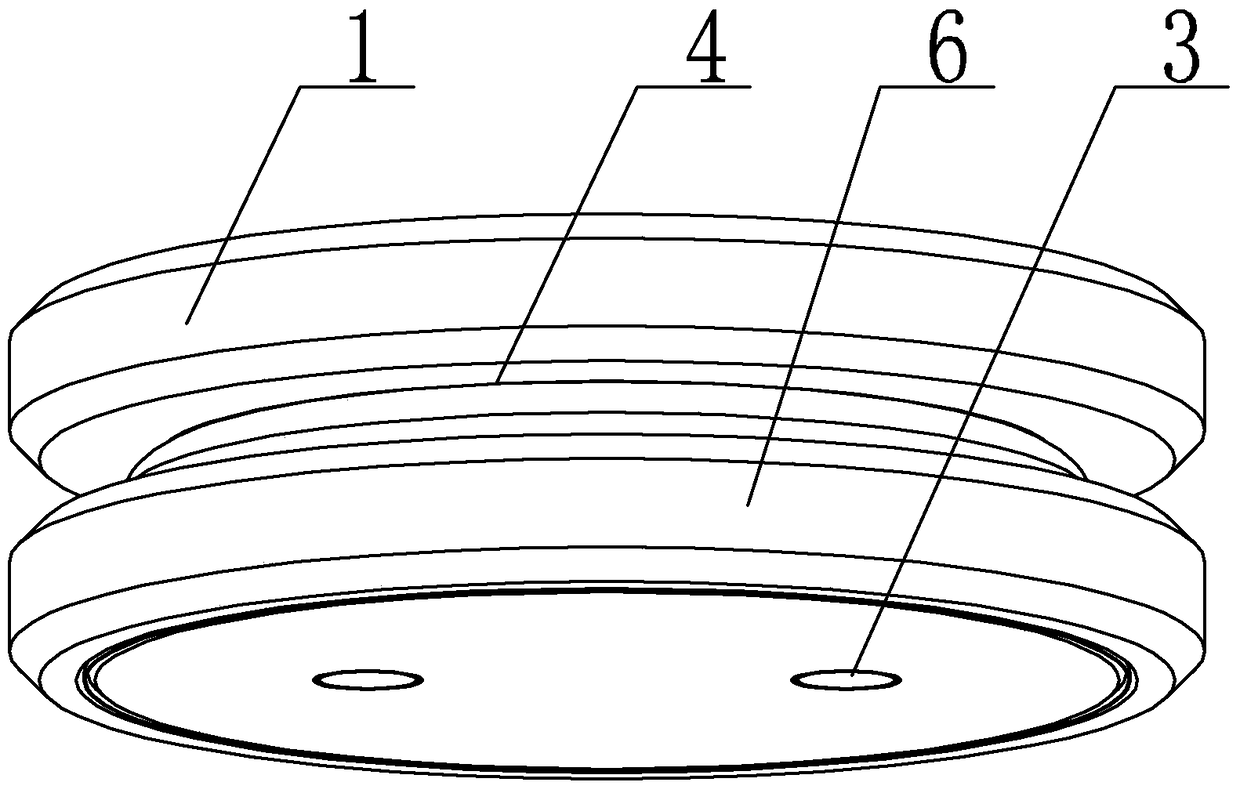

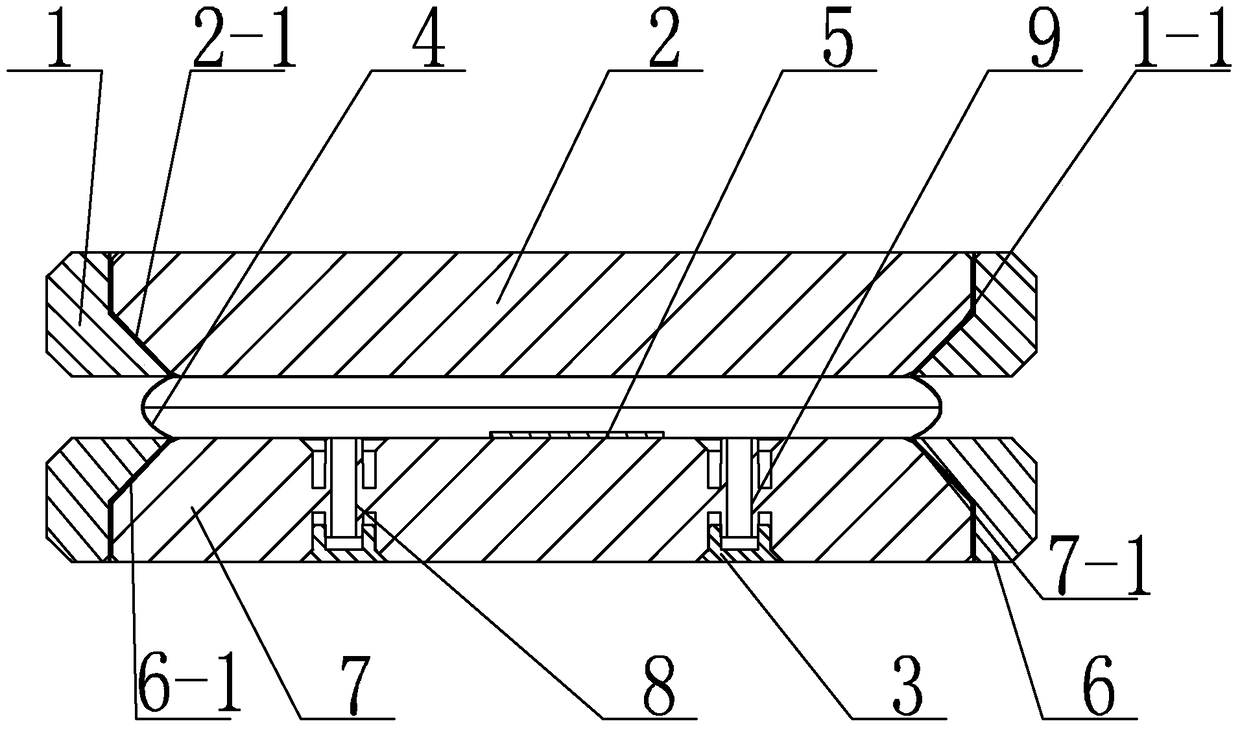

[0010] Specific implementation mode 1: Combination Figure 1-Figure 2 To explain this embodiment, a flexible pressure detection device described in this embodiment includes an upper support member 1, an upper sealing plate 2, a flexible sleeve body 4, a pressure film sensor 5, a lower support member 6, a lower sealing plate 7, The one-way inlet valve 8 and the one-way exhaust valve 9, the upper support 1 and the lower support 6 are both annular bodies, the inner side wall of the bottom end of the upper support 1 is machined with a first annular boss 1-1, and the lower support The inner side wall of the top end of the member 6 is processed with a second annular boss 6-1, the upper sealing plate 2 is arranged on the inner side wall of the upper supporting member 1, and the upper sealing plate 2 is in sealing connection with the inner side wall of the upper supporting member 1, and the lower sealing The plate 7 is arranged on the inner side wall of the lower support 6, and the low...

specific Embodiment approach 2

[0011] Specific implementation manner two: combination Figure 1-Figure 2 To explain this embodiment, the flexible pressure detection device described in this embodiment also includes two one-way valve sealing covers 3, and a one-way valve sealing cover 3 is installed on the one-way inlet valve 8 for one-way air extraction. Another one-way valve sealing cover 3 is installed on the valve 9, and the other structure is the same as the first embodiment.

specific Embodiment approach 3

[0012] Specific implementation mode three: combination Figure 1-Figure 2 To illustrate this embodiment, in the flexible pressure detection device described in this embodiment, the soft cover body 4 is made of an ultra-thin soft nano cloth that is elastic and does not leak liquid, and other structures are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com