Adhesive tape structure and adhesive tape housing

A technology for adhesive tapes and structures, applied in the direction of adhesives, film/sheet adhesives, layered products, etc., can solve problems such as the limit of long size, achieve long size, improve storage stability, The effect of suppressing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

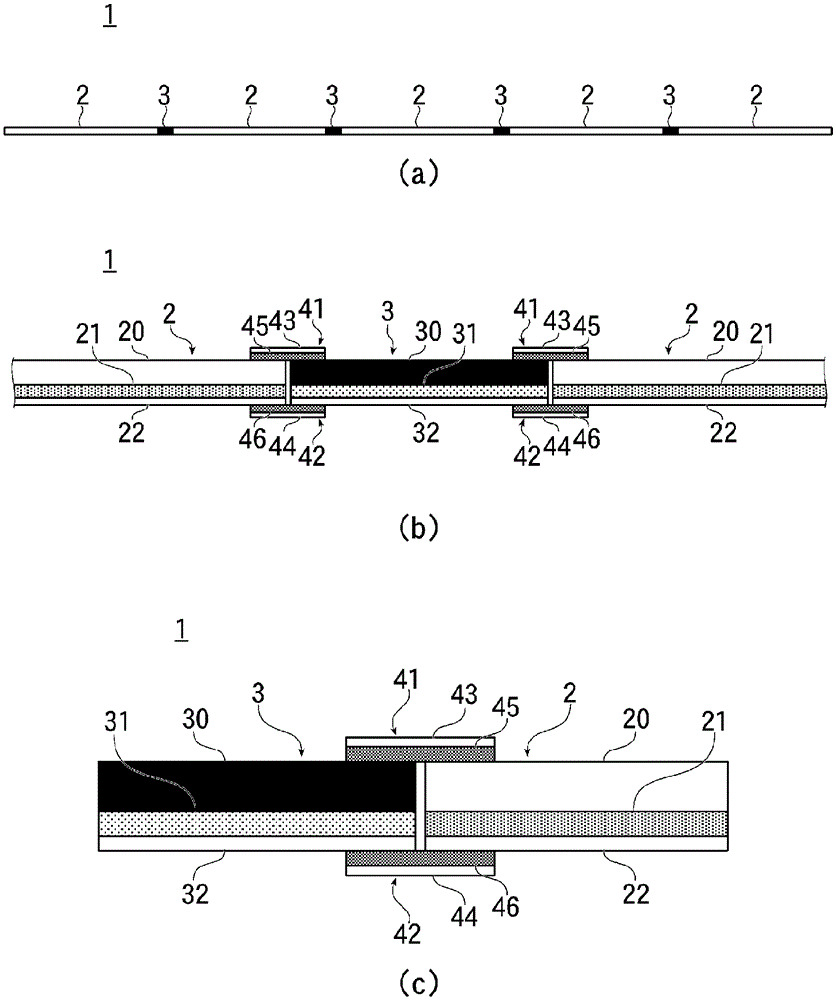

[0105] An adhesive layer and a peeling film were sequentially formed on a connection substrate made of black PET with a thickness of 50 μm to produce a connection tape.

[0106] The pressure-sensitive adhesive layer is composed of the following resin A.

[0107] That is, the composition of the resin A contains 100 parts by weight of a silicon-based resin (SD4584PSA manufactured by Toray Dow Corning Co., Ltd.), 0.7 parts by weight of a curing agent (BY24-741 manufactured by Toray Dow Corning Co., Ltd.), and a silane coupling agent. (A-187 manufactured by Momentive Performance Materials Co., Ltd.) 1 part by weight, platinum catalyst (NC-25 manufactured by Toray Dow Corning Corporation) 0.6 parts by weight.

[0108] This composition was applied to the joint base material with a rod coater, heated at 70°C for 5 minutes, and then heated at 150°C for 4 minutes to harden it to form an adhesive layer with a thickness of 20 μm.

[0109] In addition, as the release film, a release film...

Embodiment 2

[0111] As a material of the pressure-sensitive adhesive layer, a connection tape was produced on the same conditions as in Example 1 except that a material composed of the following resin B was used.

[0112] Here, the composition of resin B includes 30 parts by weight of phenoxy resin (YP-50 manufactured by Nippon Steel Chemical Co., Ltd.), 20 parts by weight of liquid epoxy resin (JER828 manufactured by Mitsubishi Chemical Corporation), and rubber component (Nagase Chemtech Co., Ltd. 10 parts by weight of SG80H manufactured by Co., Ltd., 40 parts by weight of hardener (Nobakyua 3941HP manufactured by Asahi Kasei Co., Ltd.), and 1 part by weight of silane coupling agent (A-187 manufactured by Momentive Performance Materials Co., Ltd.).

Embodiment 3

[0114] A connecting tape was produced under the same conditions as in Example 1, except that 5% by weight of a fused silica filler (FB-5D manufactured by Denka Corporation) was added to the above-mentioned resin A.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com