Adhesive tape structure and adhesive tape container

A technology of adhesive tape and structure, which is applied in the direction of adhesives, film/sheet adhesives, layered products, etc., can solve the problems such as the limit of long size, and achieve the effect of preventing bonding and realizing long size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

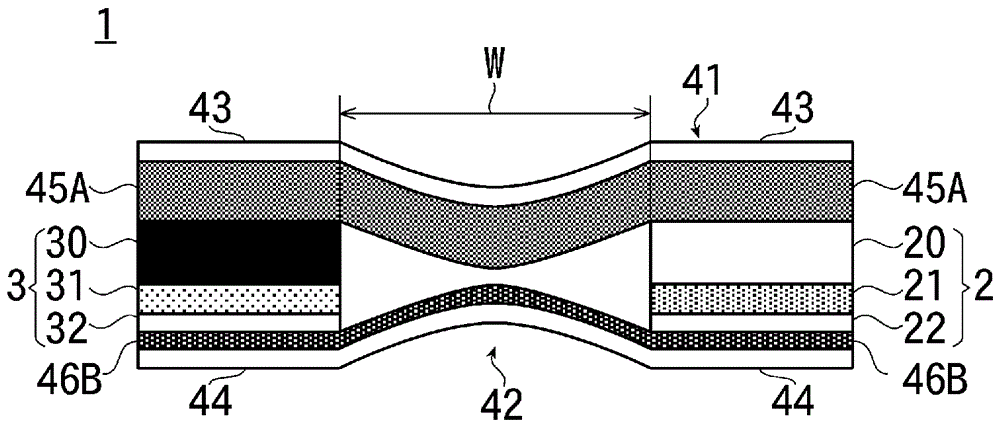

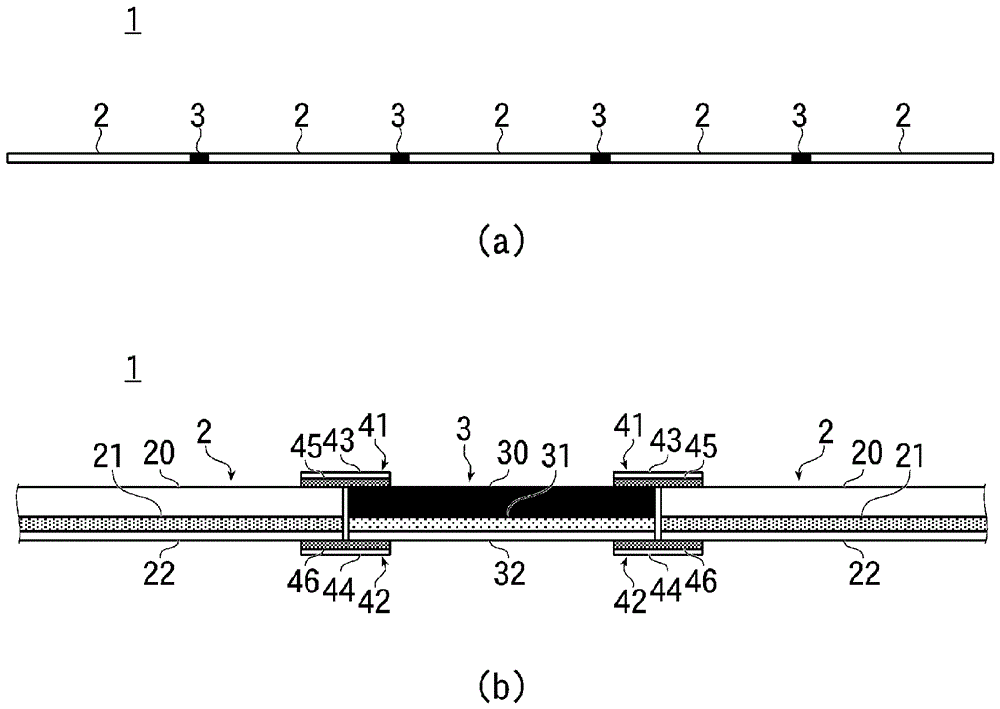

[0142] Using the above-mentioned adhesive tape and connecting tape, a Figure 5 (a) Sample of the adhesive tape structure of the structure shown.

[0143] In this case, as the substrate-side adhesive member, a silicon-based adhesive tape (Dexerials Co., Ltd. Society) system T4082S).

[0144] On the other hand, as the peeling side adhesive member, an adhesive made of acrylic resin (SK Dyne 1717 manufactured by Soken Chemical Co., Ltd.) with a thickness of 40 μm formed on a PET base material with a thickness of 38 μm was used. A silicon-based adhesive tape with a layer length of 5 cm.

[0145] Then, two adhesive tapes having a length of 50 m were bonded with the connecting tape having a length of 30 cm using the adhesive member on the substrate side and the adhesive member on the peeling side to prepare a sample of an adhesive tape structure.

Embodiment 2

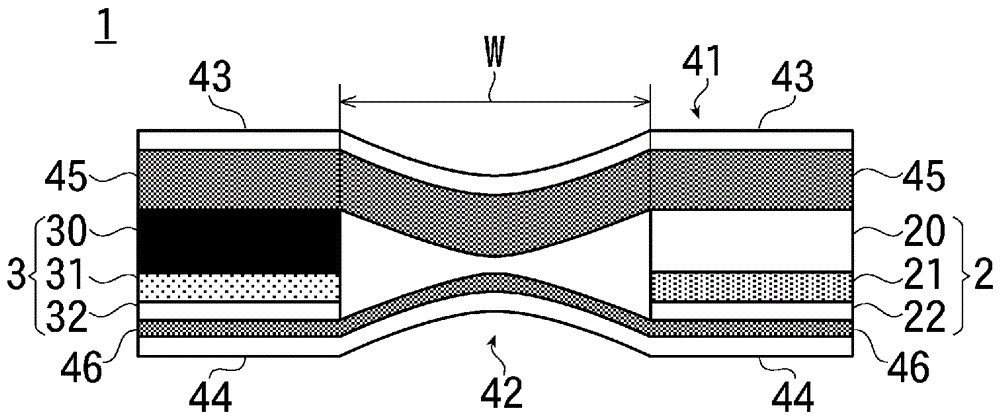

[0147] A sample of an adhesive tape structure was produced under the same conditions as in Example 1 except that the thickness of the adhesive layer of the peeling-side adhesive member was 10 μm. it is Figure 6 structure shown.

Embodiment 3

[0149] A sample of an adhesive tape structure was produced under the same conditions as in Example 1 except that the thickness of the adhesive layer of the peeling-side adhesive member was 20 μm. it is Figure 6 structure shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com