Electric kettle and flip connecting device thereof

A connecting device and flip-cover technology, which is applied in the direction of boiling water utensils, cooking utensil lids, kitchen utensils, etc., can solve the problems of impact collision, inability to overcome torque, repeated shaking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

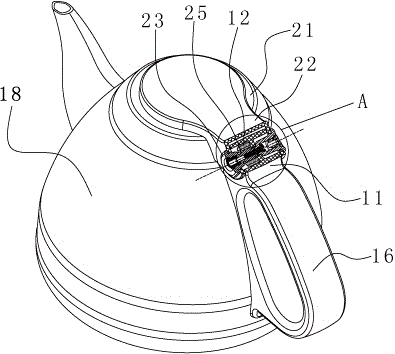

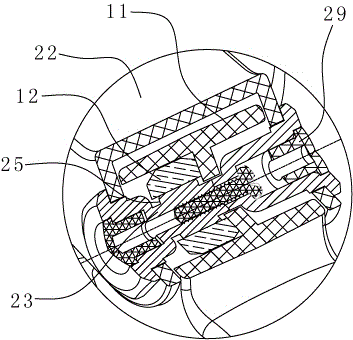

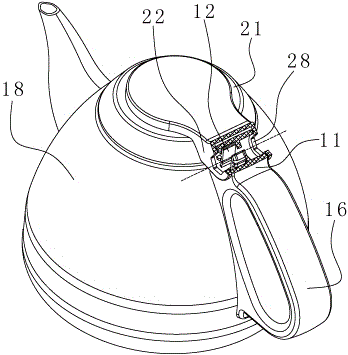

[0026] Such as Figure 1~Figure 5 As shown, the present invention is a clamshell connection device for hinged clamshell 21, which includes a support base 11, a clamshell support arm 22 that is fixedly connected and supports the clamshell 21, and is orientedly connected to the clamshell support arm 22 and inserted into the support The rotating shaft 23 of the seat 11, the elastic rubber pad 12 embedded in the supporting seat 11 and abutting against the rotating shaft 23 to play a buffer role to slow down the rotating speed of the rotating shaft 23, the rotating shaft 23 is provided with a position corresponding to the position of the elastic rubber pad 12 The eccentric projection 25 that interferes with each other, the amount of interference between the eccentric projection 25 and the elastic rubber pad 12 increases as the closing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com