A non-clogging atomizing nozzle under normal pressure

An atomizing nozzle and atomizing spray technology, applied in the direction of spray device, spray device, etc., can solve the problems of nozzle blockage, affecting spray operation, unable to spray liquid, etc., to enhance fluidity and flow rate, improve atomization effect, Good fog effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

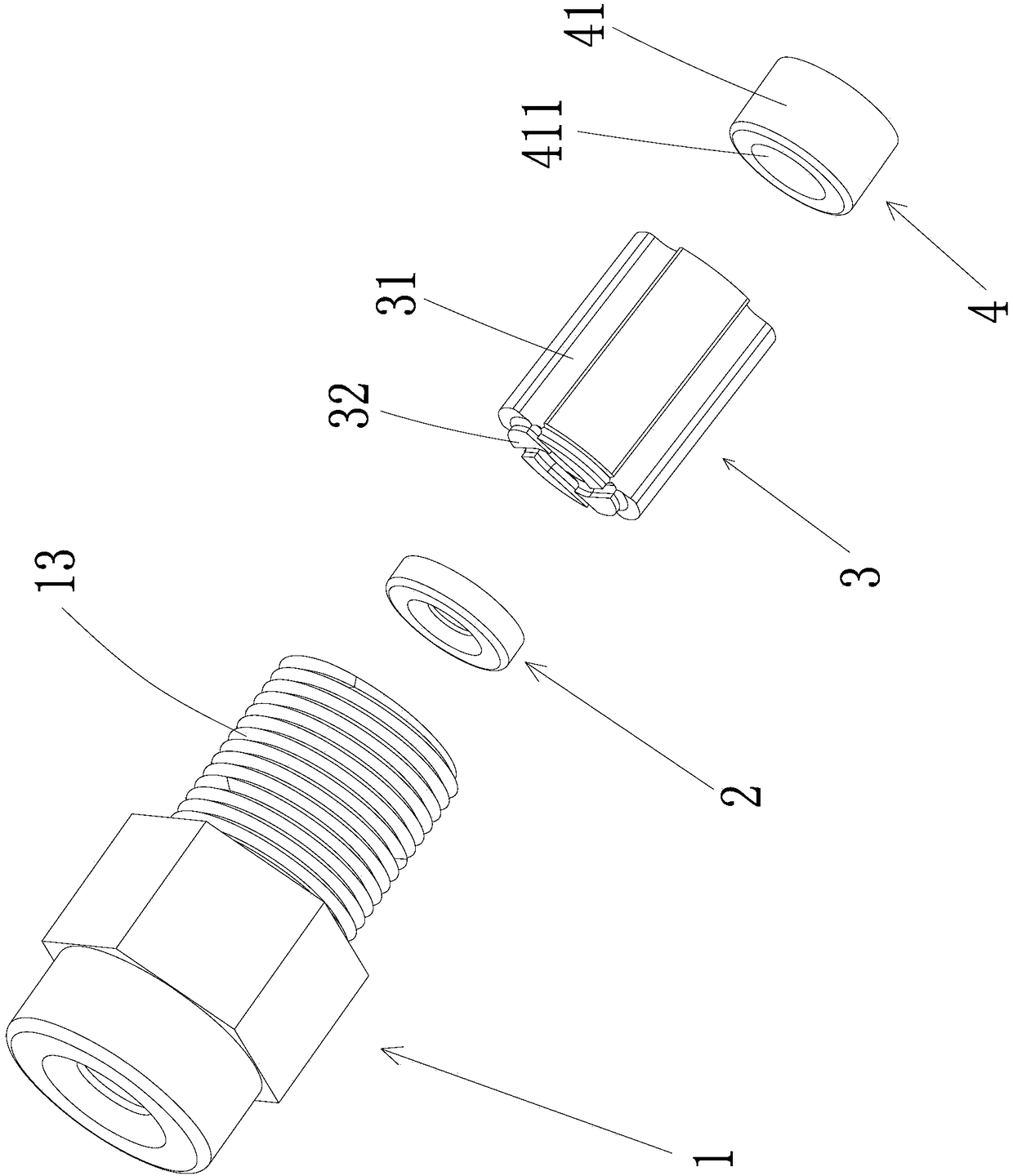

[0030] A normal pressure non-blocking atomizing nozzle, figure 1 is an exploded view of a nozzle, such as figure 1 shown, including:

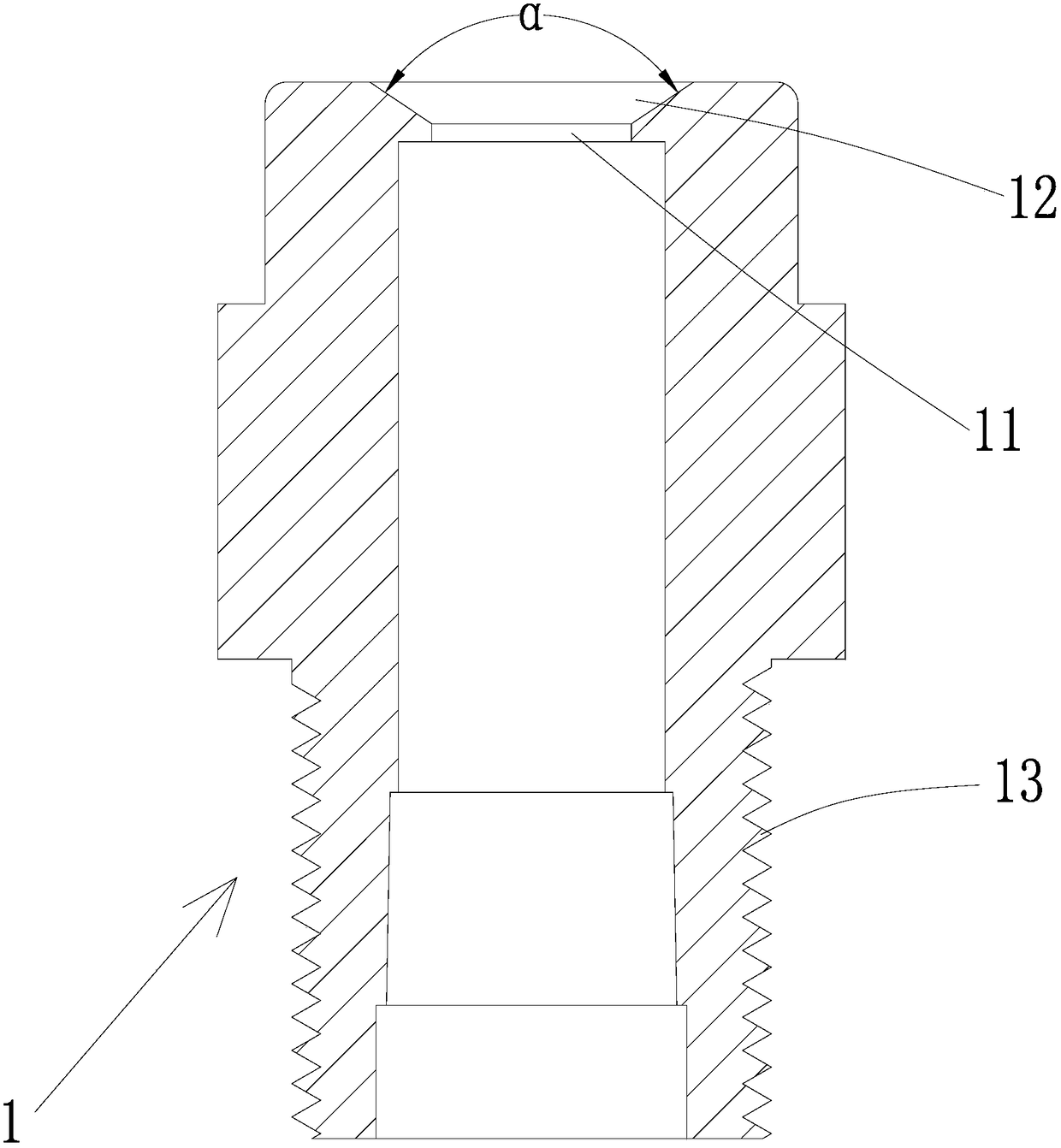

[0031] figure 2 Yes figure 1 Cutaway view of middle nozzle housing, combined figure 2 As shown, a nozzle housing 1, the first end of the nozzle housing 1 has a nozzle opening 11;

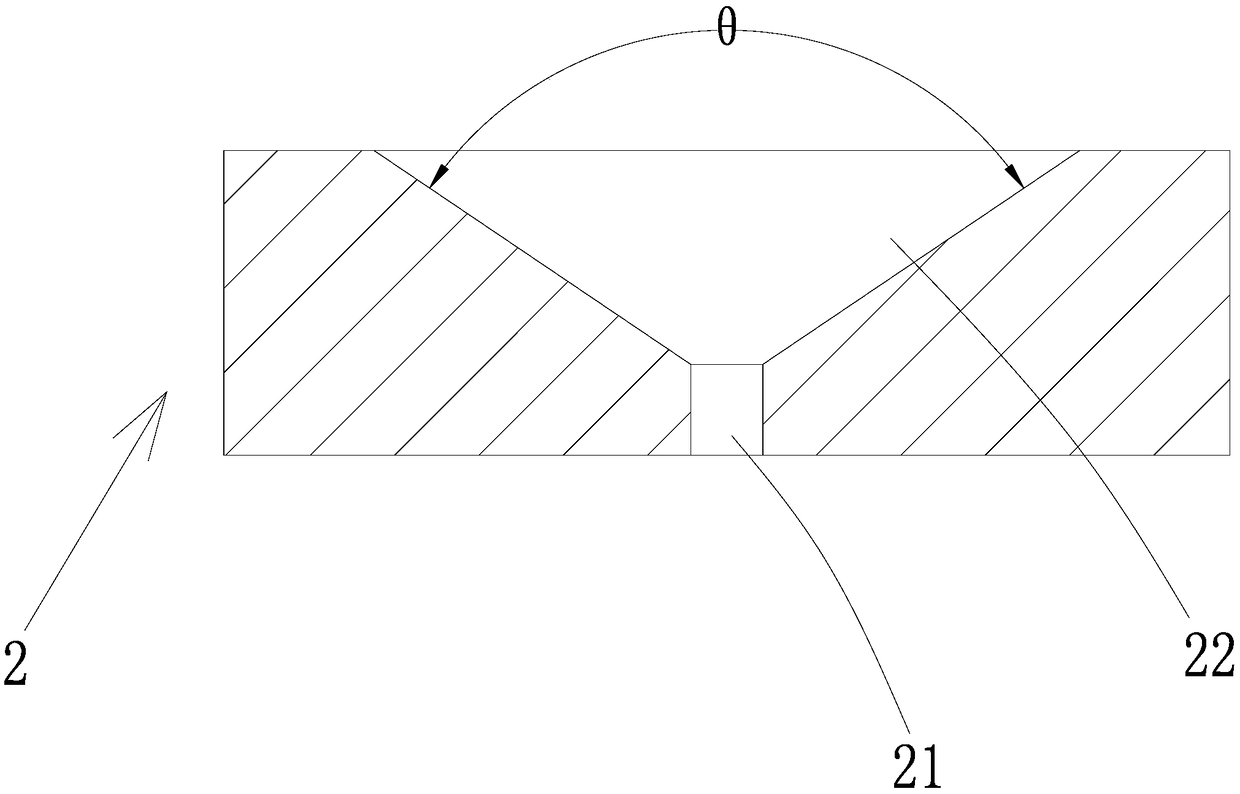

[0032] image 3 Yes figure 1 Cross-sectional view of a mid-atomizing spray plate, combined with image 3 As shown, the atomizing spray piece 2 is arranged in the nozzle casing 1, the atomizing spray piece 2 is a sheet-like structure and has at least one spray hole 21, and the atomizing spray piece 2 has a first face and second face, the first face of the atomizing spray sheet 2 faces the nozzle opening 11;

[0033] Figure 4 Yes figure 1 Structural diagram of the middle guide plug, combined with Figure 4 As shown, the diversion plug core 3, the diversion plug core 3 is arranged in the nozzle housing 1, the diversion plug core 3 is a columnar structure, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com