Separating component

A component and trough technology, applied in the field of material distribution equipment, can solve the problems of damaging the bushing surface, not having the function of material distribution, and not being able to detect whether there is a bushing in the trough, and achieve the effect of fast and accurate material distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

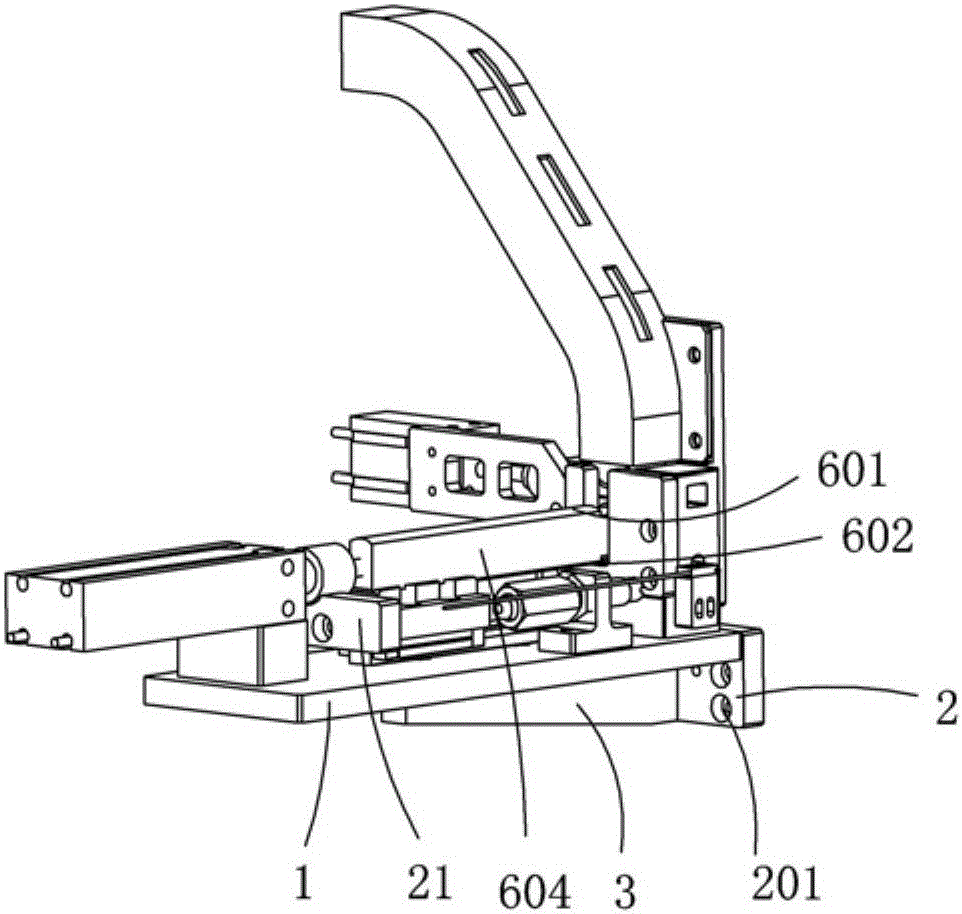

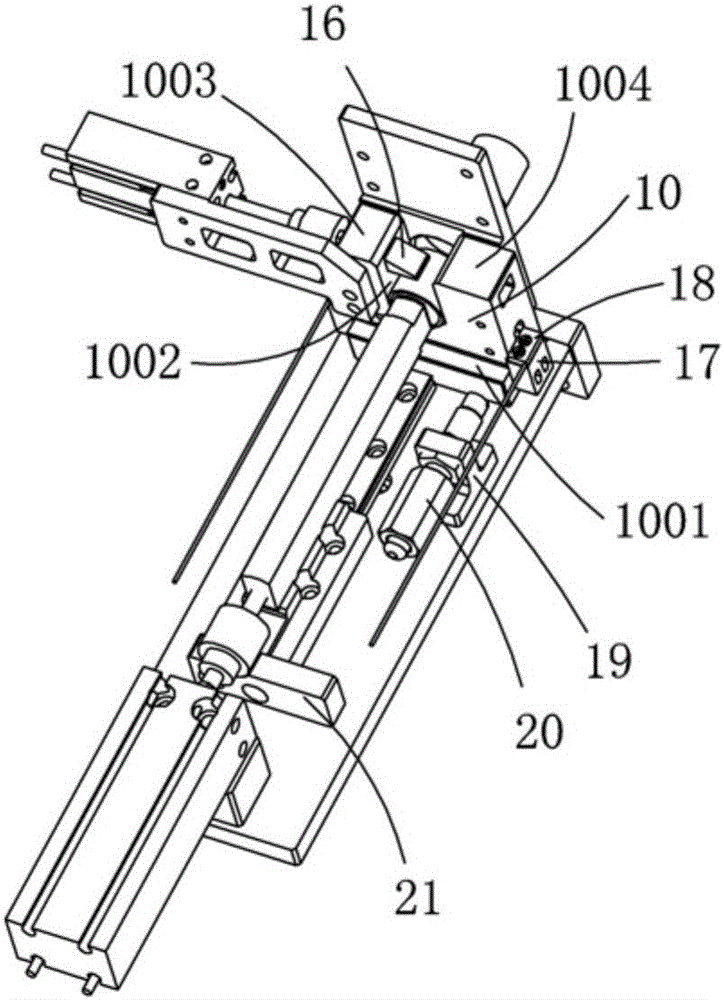

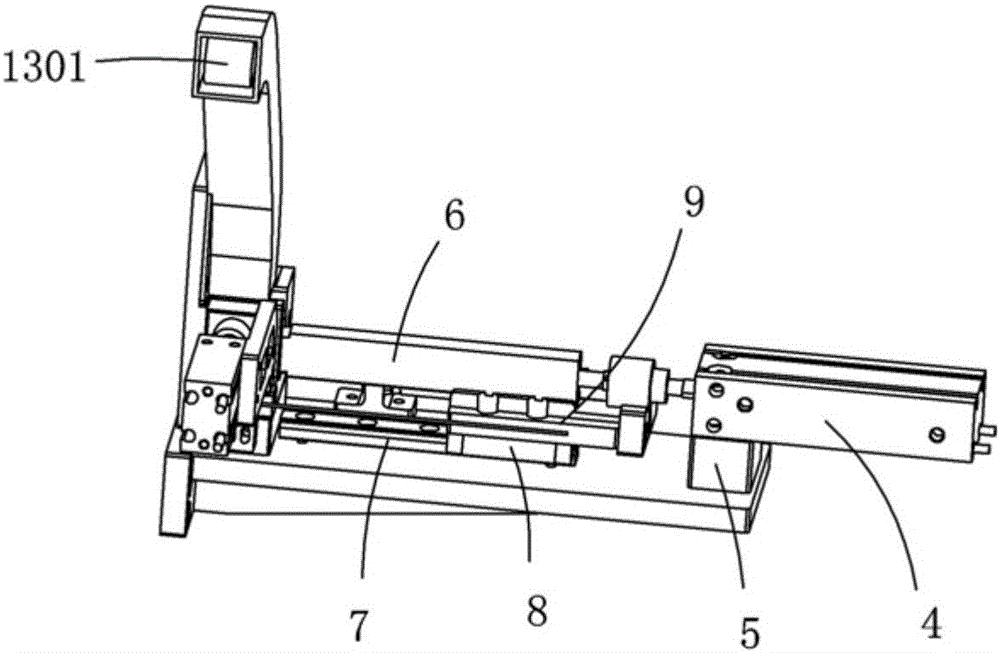

[0021] Examples, see attached Figure 1~5 , a material distribution assembly, including a fixed seat and a pushing drive device installed on the fixed seat, the fixed seat includes a fixed plate 1, a mounting block 2 installed with the end of the fixed plate 1, and a mounting block 2 installed on the fixed plate 1 and installed Rib 3 between blocks 2. In this embodiment, the fixed plate 1 is a flat plate structure, the fixed plate 1 is installed in a horizontal state, the fixed plate 1 and the installation block 2 are installed vertically, the installation block 2 is installed on the left side of the fixed plate 1, and the upper The surface is flush with the upper surface of the fixing plate 1, and the mounting block 2 is provided with a mounting hole 201, through which the mounting block 2 can be fixed on other equipment by screwing, so as to facilitate the fixing of the whole mechanism. There is one group of reinforcing ribs, which are arranged in the middle of the fixed pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com