An anti-submarine structure for the rear seat of a car

An anti-submarine-slip, seat technology, which is applied to vehicle seats, special positions of vehicles, vehicle parts, etc., can solve the problems of increasing the difficulty of seat frame design and increasing seat cost, and achieves simple structure, low cost, The effect of convenient process implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

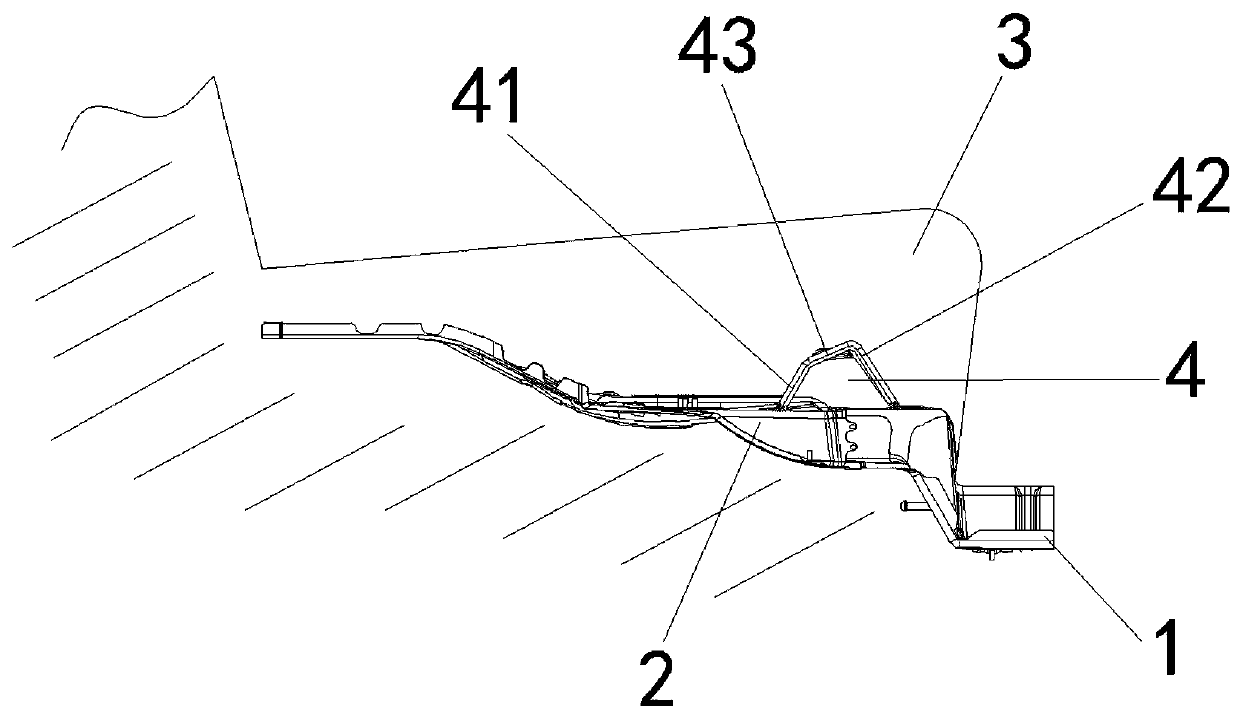

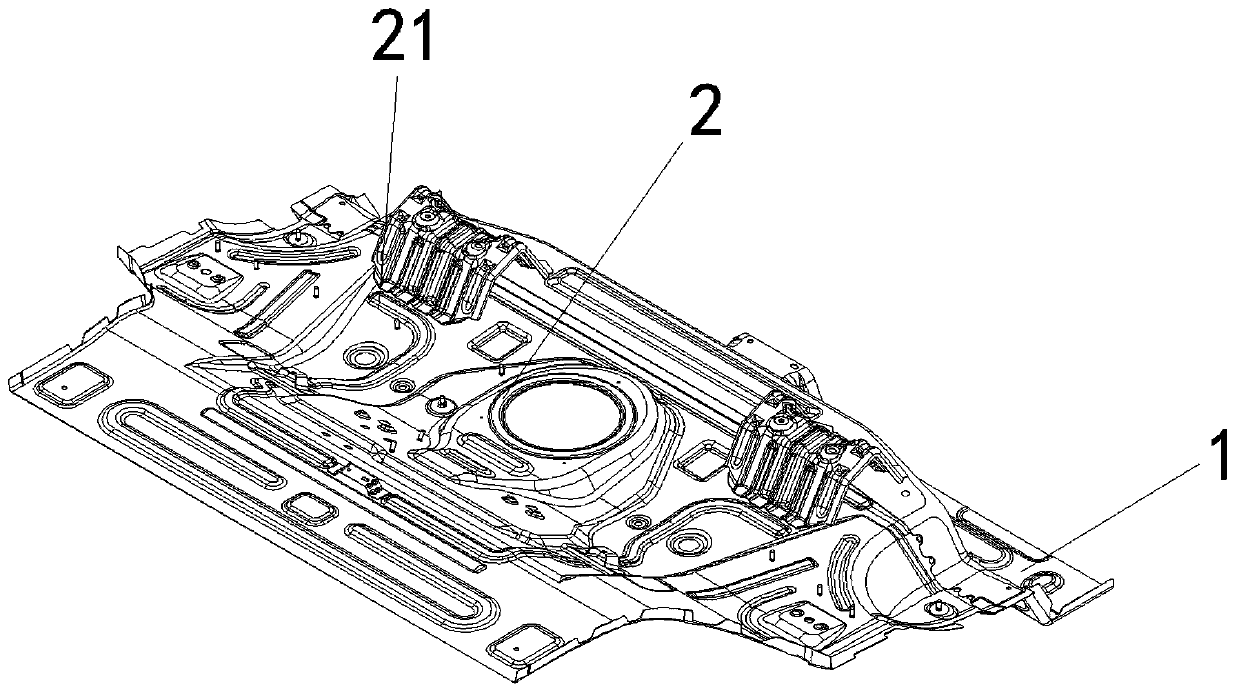

[0023] Example one, as figure 1 and figure 2 The shown anti-submarine-slip structure for a rear seat of an automobile includes an automobile chassis 1. The automobile chassis 1 includes a rear seat area 2, and a car seat 3 is provided above the rear seat area 2. An anti-submarine sliding member 4 is arranged above, a groove is formed on the car seat 3, and the anti-submarine sliding member 4 extends into the groove and the two can be tightly connected together.

[0024] The cross-section of the anti-submarine sliding member 4 is a zigzag structure, which is integrally stamped and formed from sheet metal. , the left and right directions of the anti-submarine sliding member 4 form a channel that runs through the anti-submarine sliding member 4. The hollow setting of the channel makes the support strength of the structure stronger than that of the car seat 3, preventing the structure from being easily in a submerged state. The deformation also satisfies that the structural per...

Embodiment 2

[0026] Example two, as image 3 , Figure 4 and Figure 5 The ordinary car shown has an auxiliary seat 23. In order to achieve a certain safety for the person sitting on the auxiliary seat 23, it is necessary to carry out an anti-submarine sliding design for the auxiliary seat 23. The anti-submarine sliding structure of the auxiliary seat 23 is specific. As follows, below the auxiliary seat 23 is an auxiliary seat area 22 included in the rear seat area 2 , an auxiliary anti-slip piece 5 is provided above the auxiliary seat area 22 , and the auxiliary seat 23 is provided with an auxiliary anti-slip piece 5 . The groove cooperates with the auxiliary anti-submarine sliding member 5 , so that the auxiliary anti-submarine sliding member 5 can extend into the auxiliary seat 23 during placement.

[0027] As one of the structures of the auxiliary anti-submarine-slip member 5 in the second embodiment, the auxiliary anti-submarine-slip member 5 includes an auxiliary support surface 51...

Embodiment 3

[0030] In the third embodiment, on the basis of the first embodiment, the first support surface 43 is designed as an arc surface, which matches the bending state of the knee joint and supports the thigh. When the seated person on the first support surface 43 is normally seated, the first support surface 43 is a flat plane. When the vehicle produces an instantaneous movement with excessive relative acceleration, the seated person will dive, and the dive behavior will The anti-submarine sliding member 4 can be deformed so that the seated person is comfortable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com