Trash bin capable of automatically compressing trash

A technology for garbage cans and garbage, which is applied in the direction of garbage cans, garbage collection, household appliances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

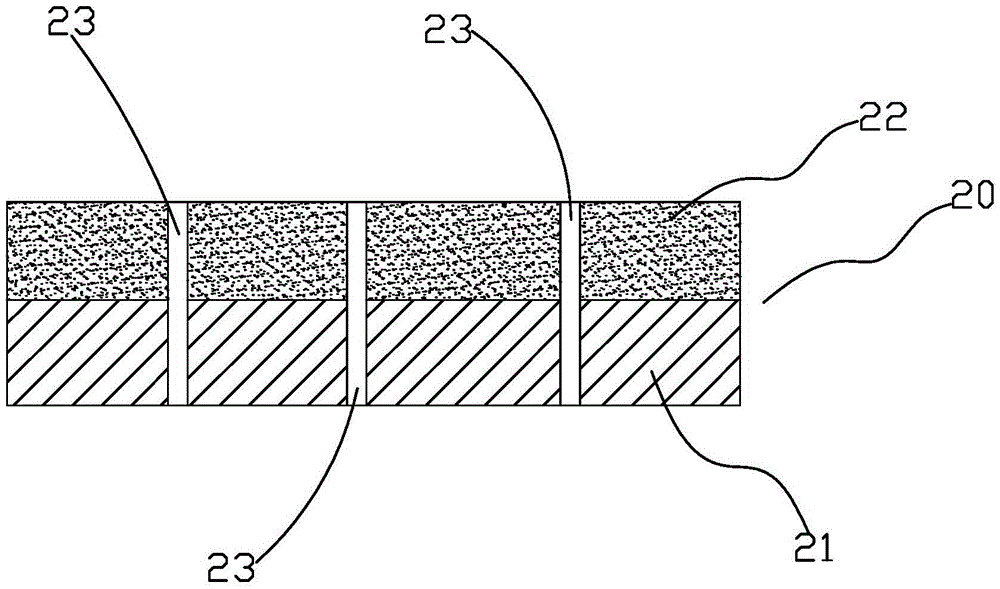

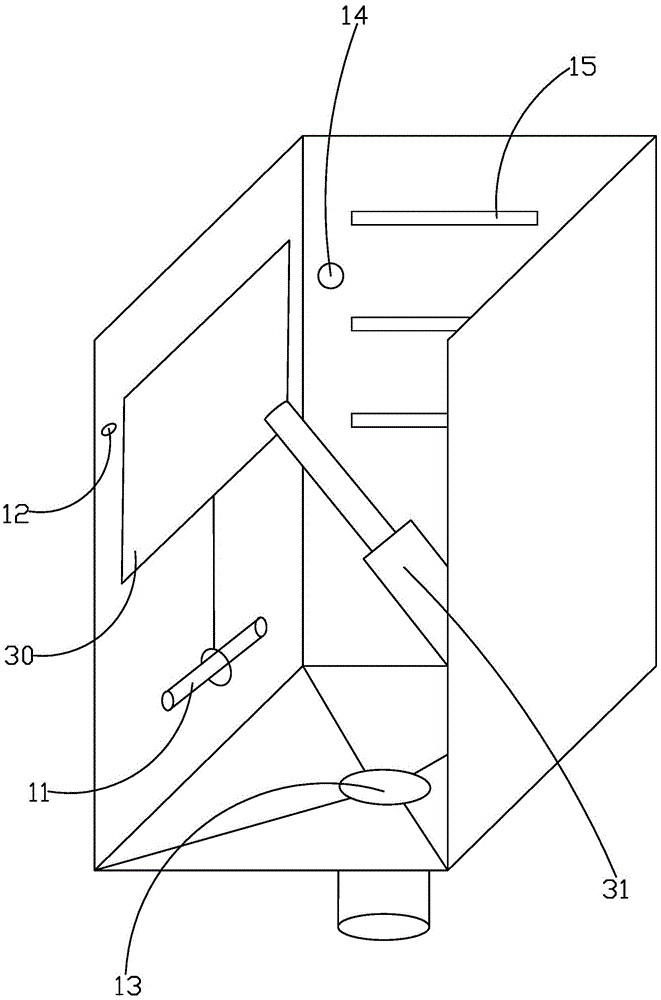

[0019] refer to Figure 1 to Figure 3 , a garbage bin capable of automatically compressing garbage, comprising a dustbin main body 10 with an upper opening, and a lid 20 that can be opened or closed at the upper opening of the dustbin main body 10 is movable, said A hinge 11 is hinged to a pressure plate 30 capable of turning over in the vertical direction on the side wall of the cavity inside the garbage bin main body 10, and the pressure plate 30 is connected with a driving mechanism 31 that drives it to turn up and down around the hinge 11. In a preferred embodiment of the present invention, the drive mechanism 31 is an air cylinder or a hydraulic cylinder. Of course, the above-mentioned drive mechanism 31 can also be replaced by a motor and a screw mechanism, which can be freely selected according to actual needs; Mechanism 31 is connected with a control circuit to control its action or not, and a detection device 12 for detecting whether the accumulation height of the gar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com