High-altitude conveying trolley and its maintenance method

A technology for transporting trolleys and maintenance personnel, applied to conveyors, mechanical conveyors, transportation and packaging, etc., can solve problems such as potential safety hazards and falling from high altitudes, and achieve safety, high safety performance, and reduce the risk of falling from high altitudes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

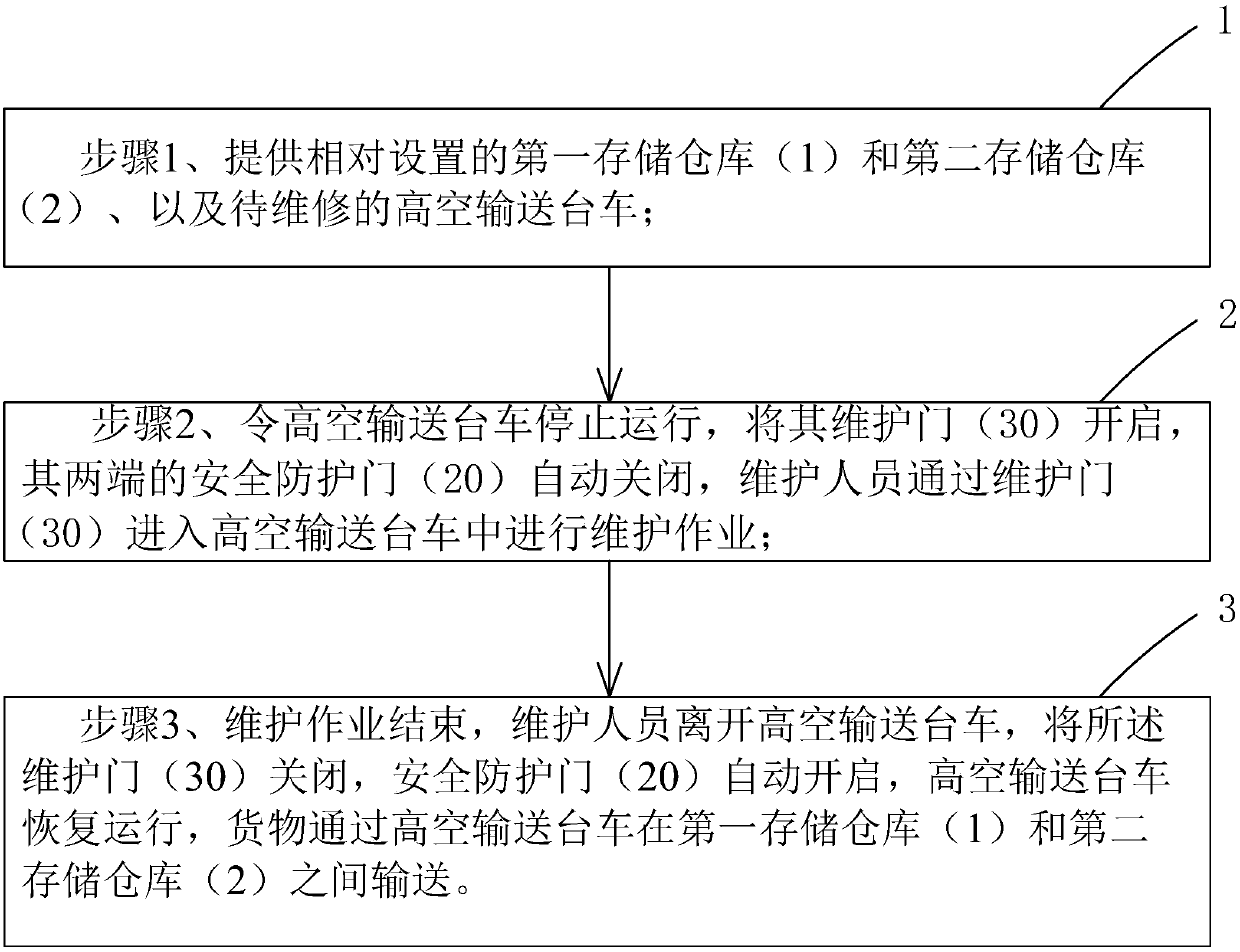

[0034] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

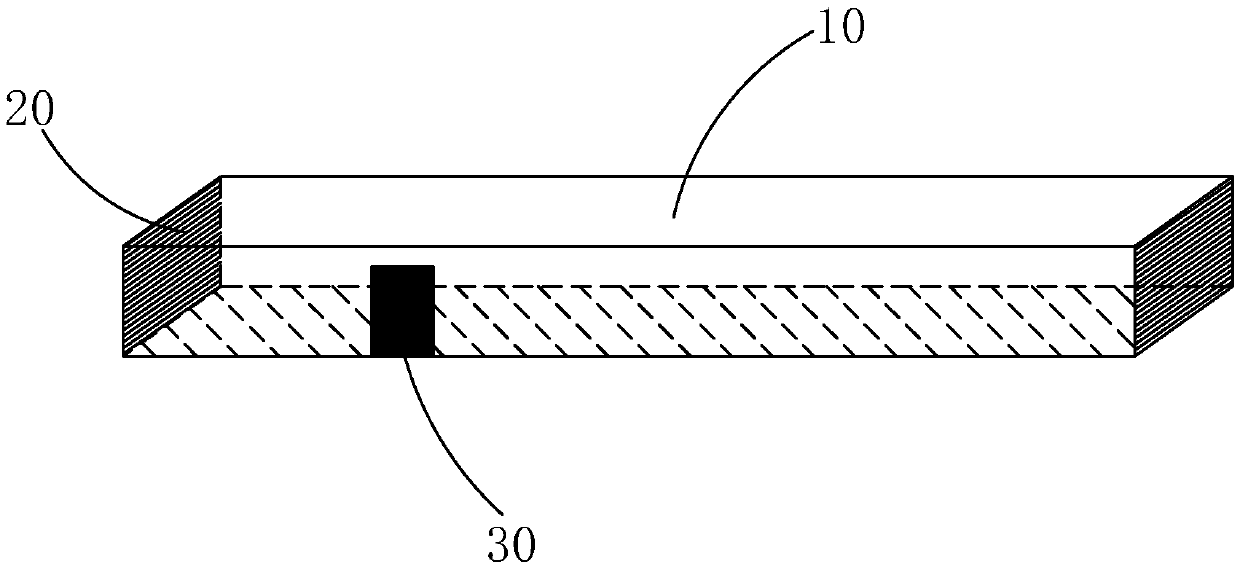

[0035] see figure 2 , The present invention provides a high-altitude conveying trolley, which is used for cargo transportation, including: a machine body 10, a safety protection door 20, a maintenance door 30, and a door lock control device.

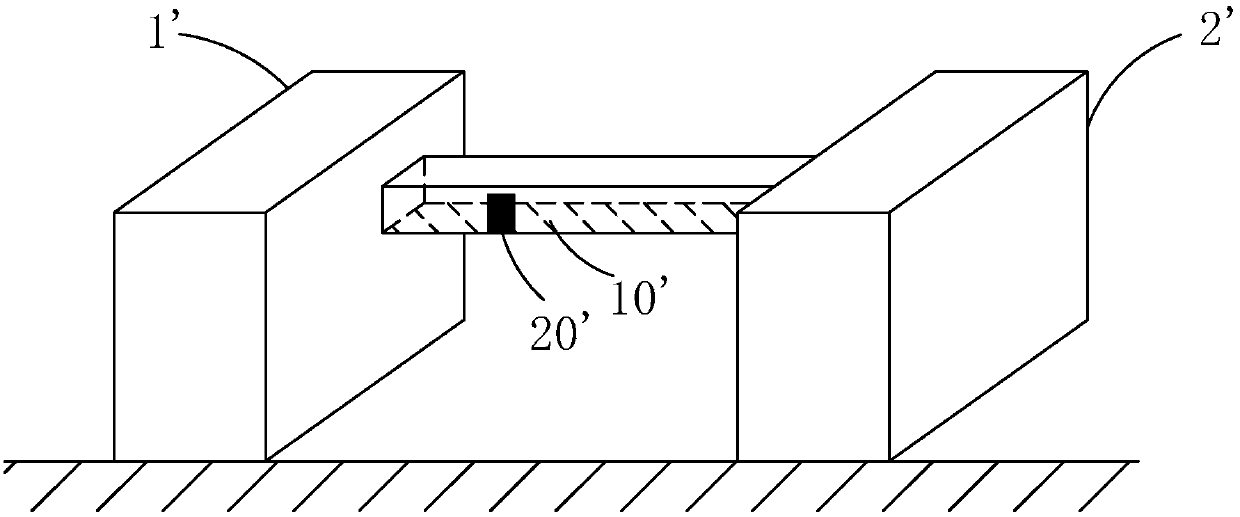

[0036] Specifically, the two ends of the machine body 10 are respectively connected to two storage warehouses that need to transport goods. The height of the bottom plate of the table body 10 from the ground is more than 3m, so that there is enough space under the high-altitude conveying trolley for other work in the production workshop.

[0037] Specifically, there are two safety protection doors 20, which are respectively arranged at the two ends of the machine body 10, that is, the high-altitude ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com