Lock body with double unlocking method

A double lock-body technology, applied in non-mechanical transmission-operated locks, building locks, electric alarm locks, etc., can solve problems such as user inconvenience, lock design constraints, lock appearance, and unfavorable functions, and achieve easy installation and compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

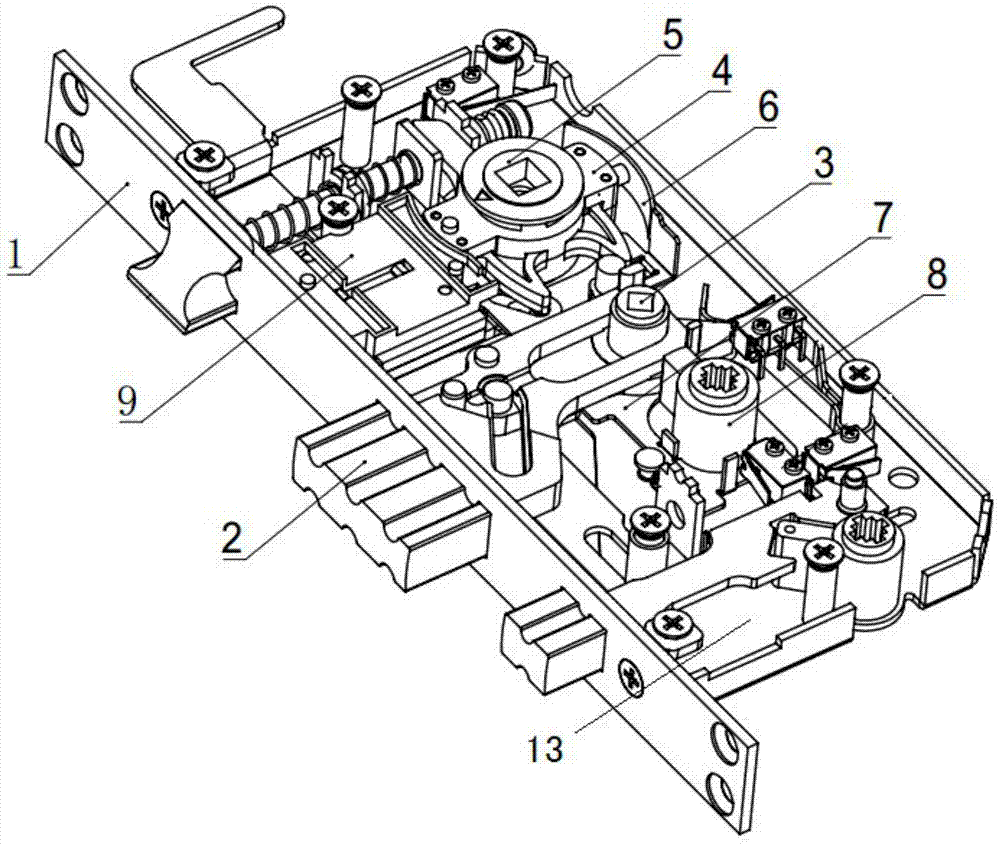

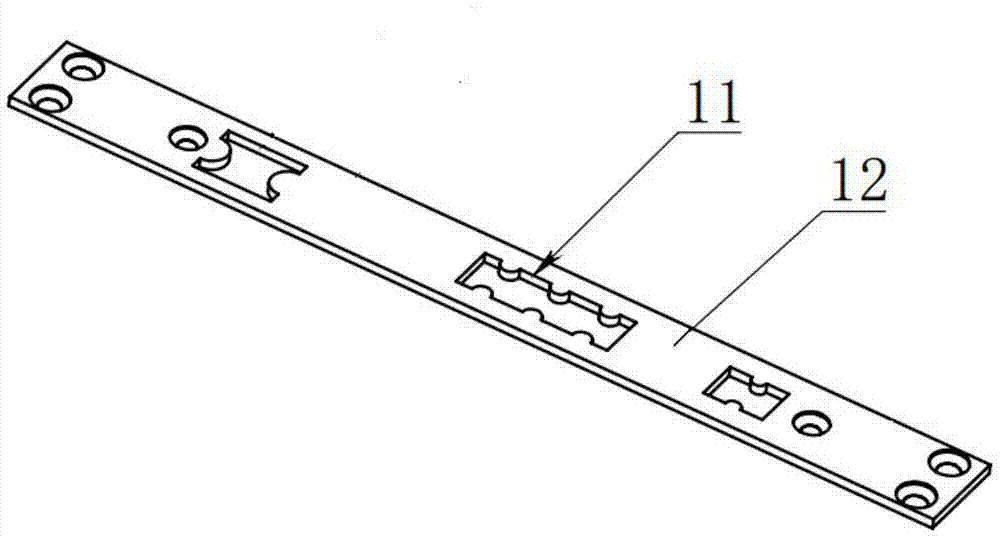

[0027] The lock body with double unlocking mode includes a housing 1. The housing 1 includes a mounting plate 13 and a bolt guide plate 12 fixed perpendicularly to the mounting plate 13. The bolt guide plate 12 is provided with a bolt guide hole 11 and the mounting plate 13 A lock tongue 2 that can telescopically slide in the lock tongue guide hole 11 is provided.

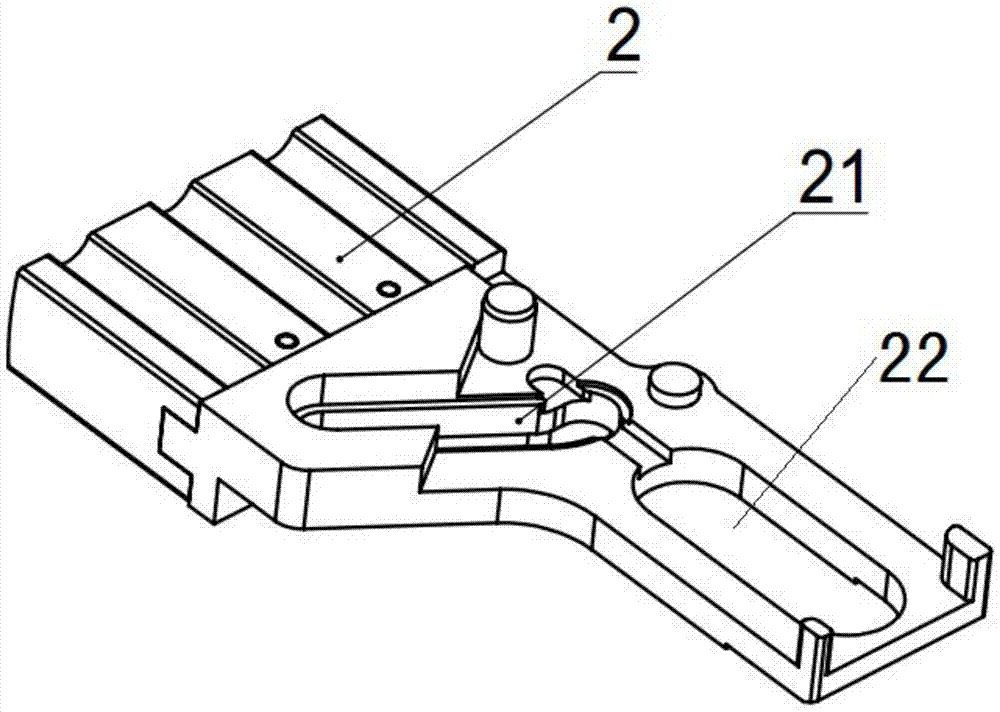

[0028] The lock body also includes a bolt shift fork 3, a manipulator assembly 4, and a handle seat 5 all fixed on the mounting plate 13. The bolt shift fork 3 is provided with a first bolt slide groove 21 and a second bolt slide Slot 22, wherein the length direction of the second bolt slide groove 22 is the same as the bolt extension direction, and the length direction of the first bolt slide groove 21 and the length direction of the second bolt slide groove 22 form an angle of 120°-135° , The latch fork 3 is provided with a first fork shaft 31, a second fork shaft 32, and a main fork shaft 33 slidably connected to t...

Embodiment 2

[0035] The same as the first embodiment, the difference is that the electronic clutch driver 9 is driven by an electromagnet to control the movement of the driving plate 91, and then unlocks or locks the entire lock.

Embodiment 3

[0037] The lock body with double unlocking mode includes a housing 1. The housing 1 includes a mounting plate 13 and a bolt guide plate 12 fixed perpendicularly to the mounting plate 13. The bolt guide plate 12 is provided with a bolt guide hole 11, and the mounting plate 13 is A lock tongue 2 that can telescopically slide in the lock tongue guide hole 11 is provided.

[0038] The lock body also includes a bolt shift fork 3, a manipulator assembly 4, and a handle seat 5 all fixed on the mounting plate 13. The bolt shift fork 3 is provided with a first bolt slide groove 21 and a second bolt slide Slot 22, wherein the length direction of the second bolt slide groove 22 is the same as the bolt extension direction, and the length direction of the first bolt slide groove 21 and the length direction of the second bolt slide groove 22 form an angle of 120°-135° , The latch fork 3 is provided with a first fork shaft 31, a second fork shaft 32, and a main fork shaft 33 slidably connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com