Magnet apparatus of an electrical machine with a coolant line

A technology of coolant and magnetic device, applied in cooling/ventilation devices, electromechanical devices, electrical components, etc., can solve the problem of leakage location is not simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The examples to be described in detail below are preferred embodiments of the present invention.

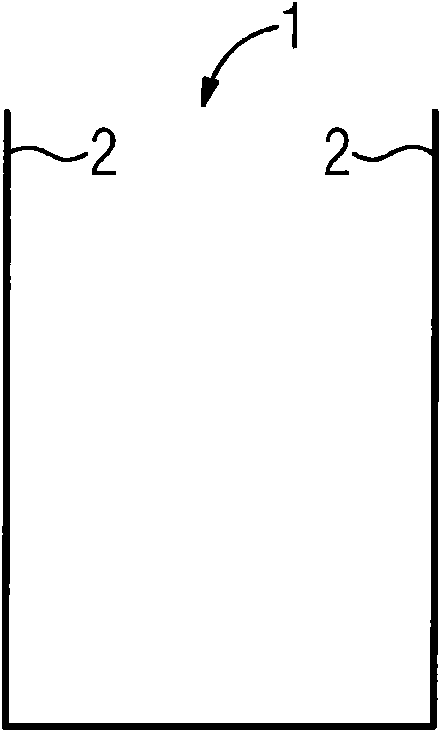

[0022] figure 1 Shown is a U-shaped first coolant pipe section 1 . It has two mutually parallel sides 2 of equal length, each of which has a free side end 2 .

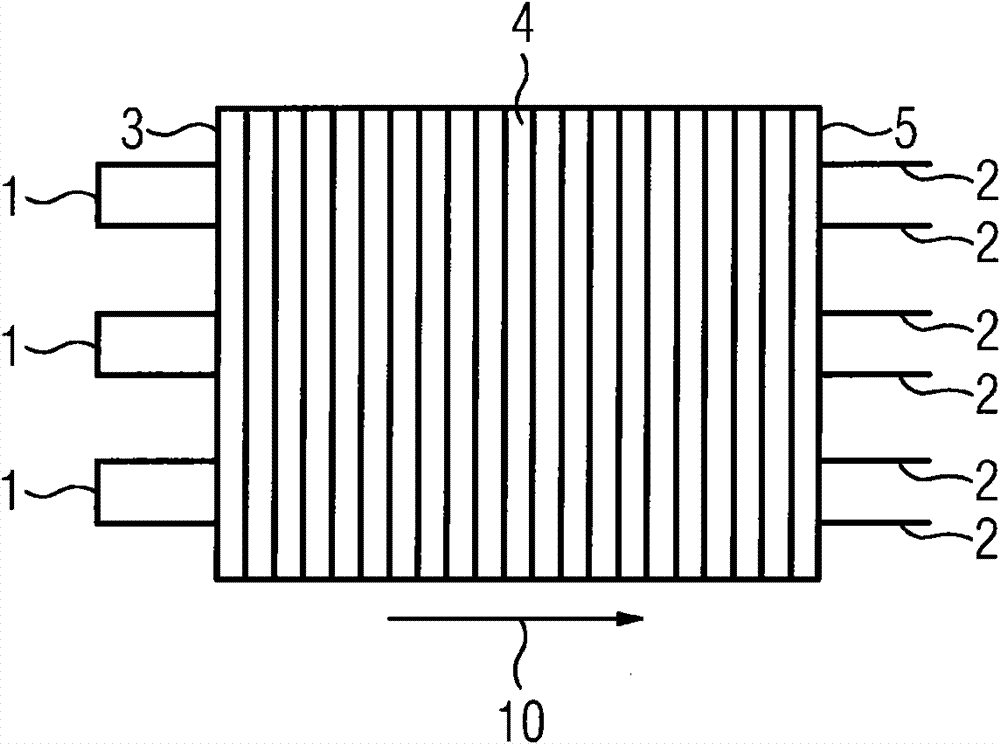

[0023] Such as figure 2 As shown, a plurality of first coolant pipe sections 1 of this type are inserted from one side 3 of the stator lamination stack 4 into corresponding bores (commonly called "channels") of the stator lamination stack 4 . The insertion direction of these first coolant pipe sections is determined by figure 2 Indicated by the arrow 10 in. The side length of any first coolant pipe section 1 is such that the side end 2 protrudes beyond the second side 5 of the stator lamination stack 4 , which is arranged opposite to the first side 3 . All the cooling passages of the ferromagnetic substrate (here designated as the sub-lamination stack 4 ) are installed with the first coolant pipe section 1 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com