Nanofiber spherical silicon-based heterogeneous Fenton catalyst as well as synthetic method and application thereof

A technology of nanofibers and synthesis methods, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problem of low activity of heterogeneous Fenton catalysts, low utilization rate of hydrogen peroxide, and inability to free molecules Contact and other issues, to achieve the effect of easy recycling, easy access, high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

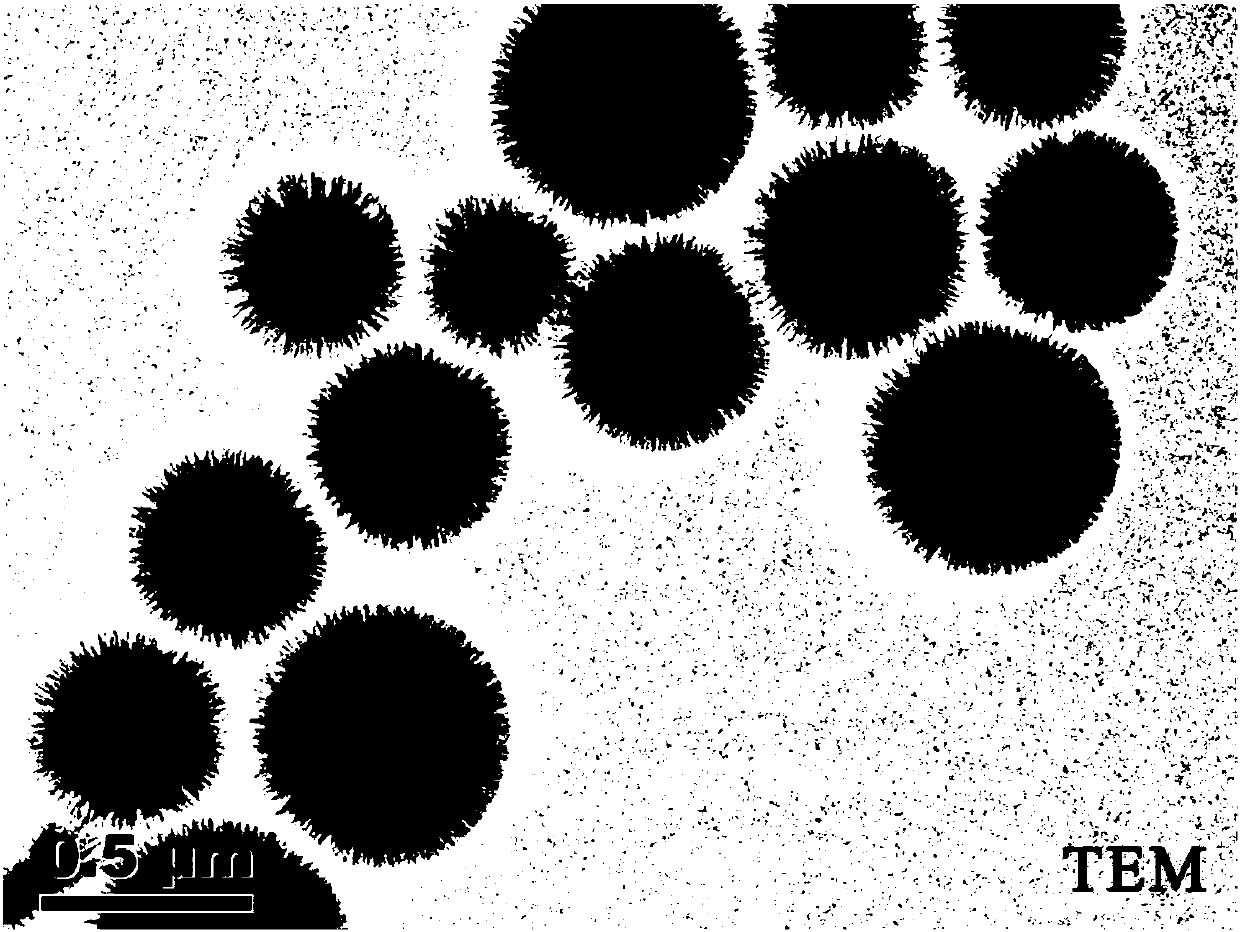

[0041] Nanofibrous spherical silicon-based heterogeneous Fenton catalyst F-Cu-SiO of the present invention 2 The synthetic method of NSs, comprises the following steps:

[0042] (1) Dissolve 5.0 mL of TEOS into a mixed solution consisting of 3.0 mL of n-pentanol and 50.0 mL of cyclohexane to form solution A.

[0043] (2) Dissolve 1.0 g of urea and 2.0 g of CPBH into 50.0 mL of deionized water to form solution B.

[0044](3) After A and B were mixed and stirred for 60 minutes, according to the molar ratio Si / Cu=50, Cu(NO 3 ) 2 ·3H 2 O solution, the resulting solution was continuously stirred at 45 °C for 60 min. The stirring speed described in this step is 450 rpm.

[0045] (4) The solution obtained in the above steps was placed in a high-pressure reactor, and the whole was placed in an oven at 120° C. for 5 hours.

[0046] (5) Take out the autoclave, and after natural cooling, filter the obtained solid product, alternately wash five times with deionized water and aceton...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com