Single electronic detonator bridge wire and production method thereof

A technology of electronic detonators and production methods, which is applied in the direction of detonators, weapon accessories, fuzes, etc., and can solve problems such as the inability to meet the requirements of the patch process, the size of the ignition head of the detonator, and the large size of the structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

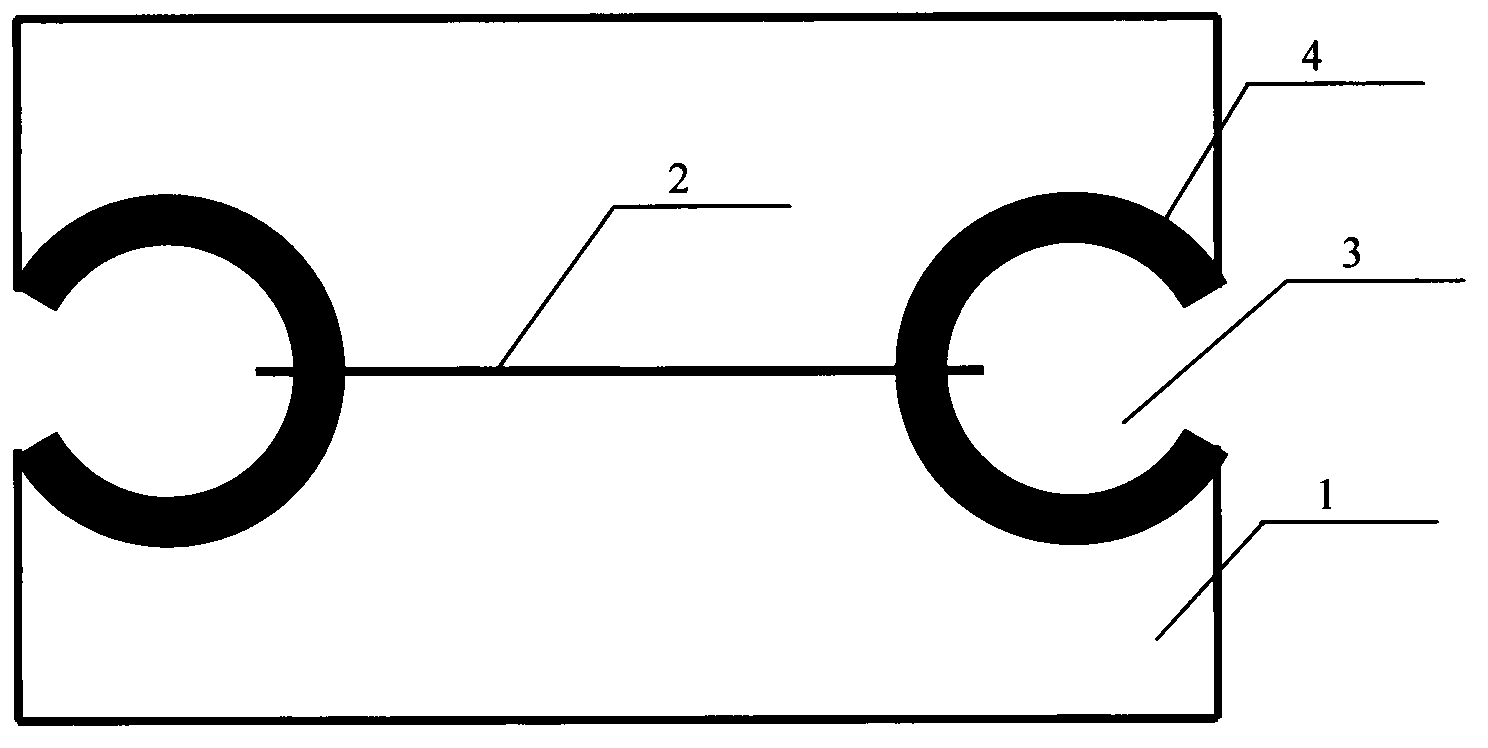

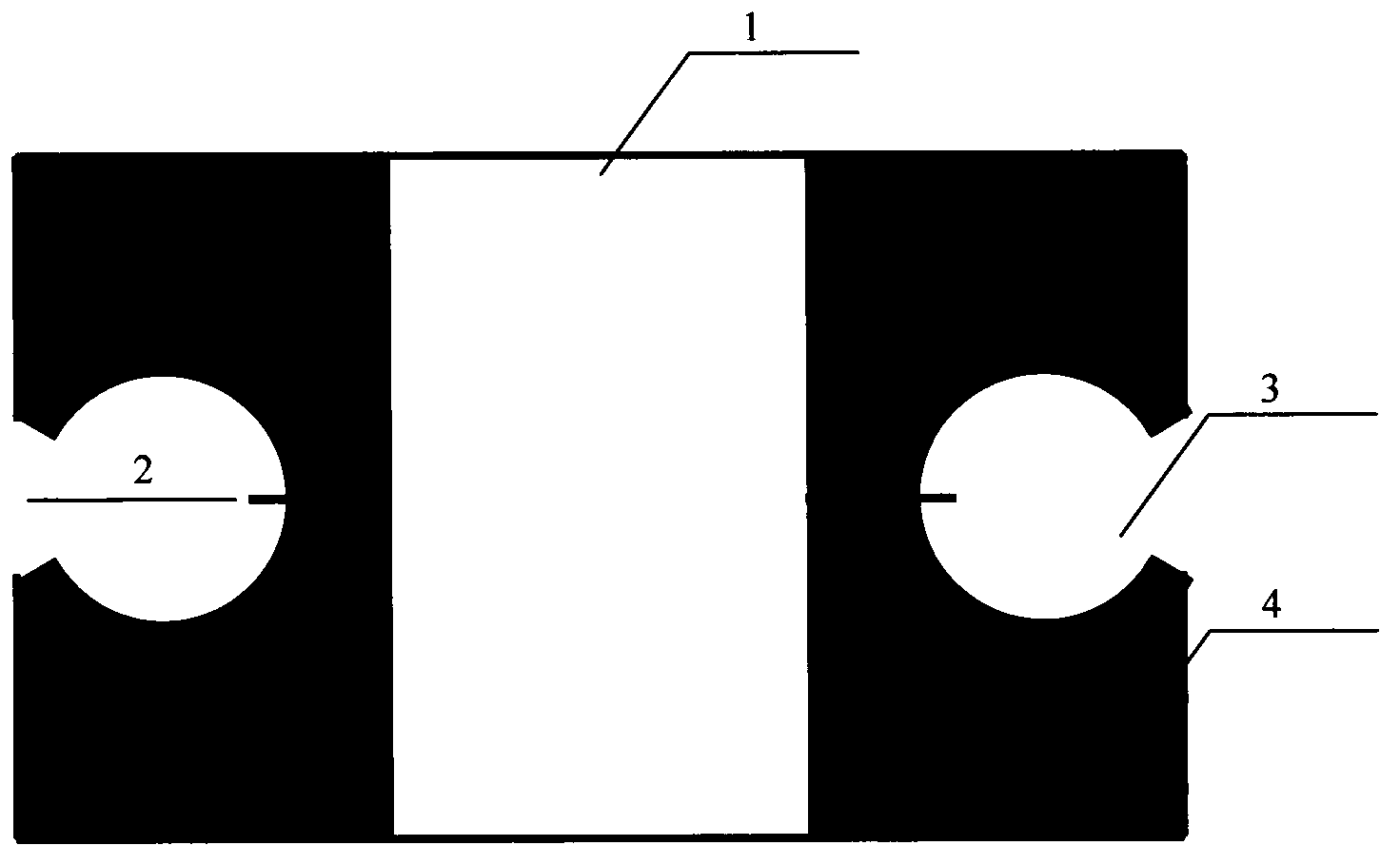

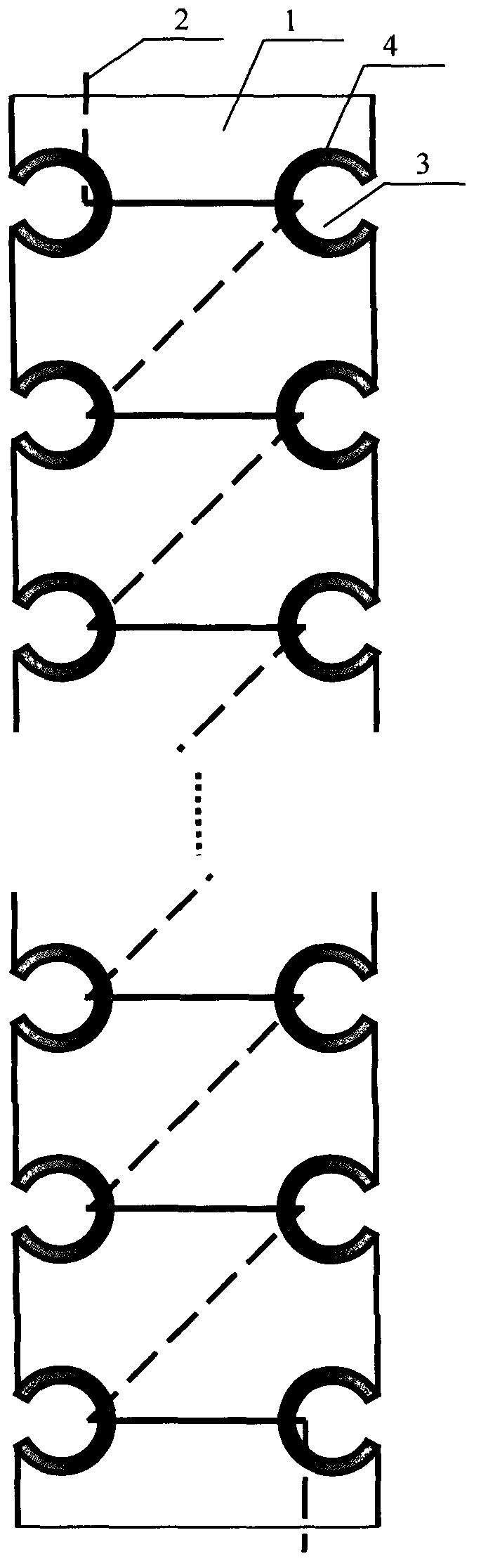

[0028] refer to Figure 1 to Figure 2 , the electronic detonator bridge wire monomer of the present invention comprises a substrate 1, an alloy wire 2, and the substrate 1 is covered with a metal film on both sides, such as a copper film. One side of the substrate is the surface where the alloy wire 2 is located, and the other side is the surface where the pad 4 is located. Both sides of the substrate 1 are provided with slots 3 , and the alloy wire 2 passes through the slots 3 and is wound on the substrate 1 . refer to Figure 3 to Figure 4 , the production method of electronic detonator bridge wire monomer of the present invention comprises the steps:

[0029] (1) Process a double-sided metal-clad substrate 1 with several pairs of slot holes 3;

[0030] (2) coating the solder paste on the substrate 1;

[0031] (3) passing the alloy wire 2 through the slot hole 3 and winding it on the substrate 1;

[0032] (4) Spray flux;

[0033] (5) Carry out corresponding bonding and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com