Axially split pump

An axial and split technology, applied in the direction of radial flow pumps, pumps, pump components, etc., can solve the problems of reduced pump efficiency and environmental pollution, and achieve the effects of simple installation, simple manufacture, and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

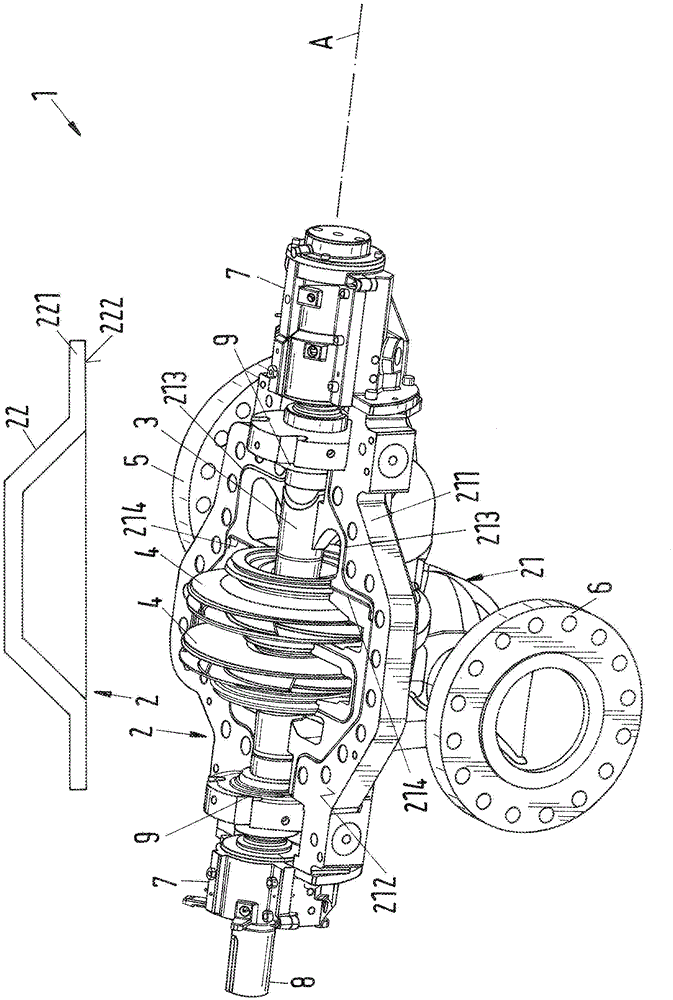

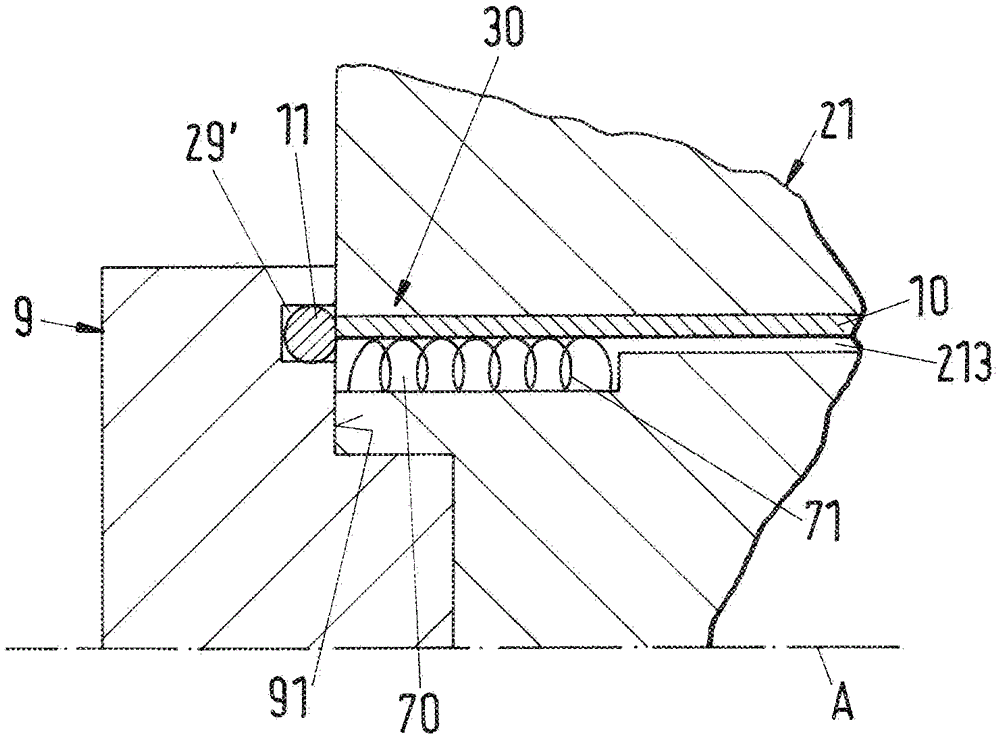

[0042] figure 1 An embodiment of the axially split pump according to the invention, indicated generally by reference number 1 , is shown in a perspective view. The pump 1 comprises a housing 2 which is split axially and has a bottom 21 and a cover 22 . For better understanding, cover 22 is in figure 1 removed and indicated only symbolically. image 3 A top view of the bottom 21 of the housing 2 of this embodiment is shown.

[0043] The housing 2 comprises an inlet 5 for taking in the fluid to be delivered and an outlet 6 for the fluid. The pump 1 also comprises a rotatable shaft 3 , the longitudinal direction of which defines the axial direction A . Mounted rotatably fixed at the shaft 3 is at least one impeller 4 , in the present case two impellers 4 conveying the fluid from the inlet 5 to the outlet 6 . Furthermore, corresponding bearing arrangements 7 are provided at both ends with respect to the axial direction A of the pump 1 in order to support the shaft 3 of the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com