Nondestructive testing structure for submarine pipe in tidal range zone, processing method and testing method

A technology of non-destructive testing and processing methods, which can be applied to measuring devices, using sonic/ultrasonic/infrasonic waves to analyze solids, and using sonic/ultrasonic/infrasonic waves for material analysis, etc. High, can not completely cut off the protective tube and other problems, to achieve the effect of winding tightening, high accuracy, and ensuring transmission and reception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

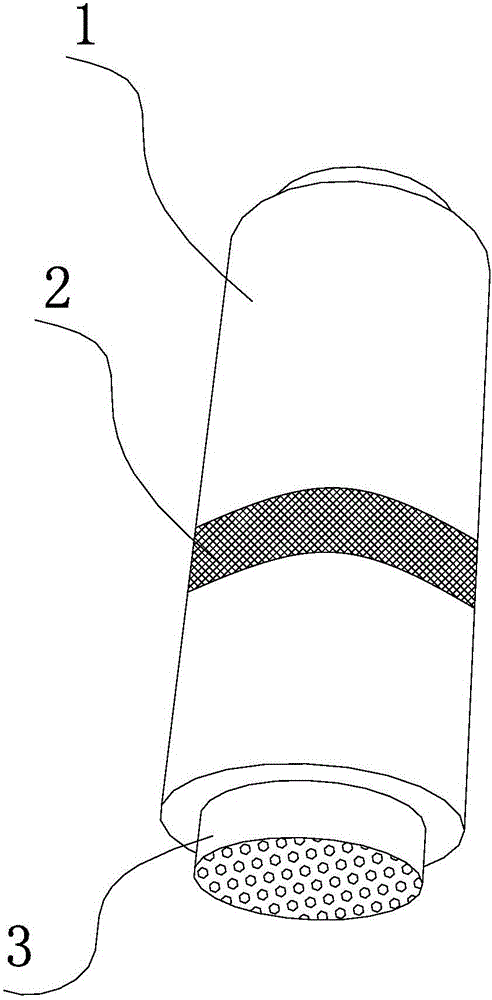

[0029] see figure 1 , a non-destructive testing structure for sea pipes in tidal range areas, comprising a sea pipe 3 with a protective pipe 1 sleeved on the outer wall; the sea pipe 3 is located at the standpipe position at the landing end or departure end; It is a magnetized magnetic sea pipe; on the protective tube 1, a gap with an axial length of a is provided; in the above-mentioned gap, an iron-cobalt belt 2 with a length a is arranged; on the outer surface of the above-mentioned iron-cobalt belt 2, Covered with epoxy resin glue; the iron-cobalt tape 2 is pasted on the outer surface of the sea pipe 3; the circumferential dimension of the gap is not less than half of the circumference of the protective pipe 1. In the preferred embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com