A material combustion experimental device simulating a low-pressure environment

An experimental device and low-pressure environment technology, applied in the direction of using combustion for chemical analysis, etc., can solve the problems of less research on fire prevention, the inability to control atmospheric pressure environmental factors, and the inability to simulate the combustion process of materials, so as to achieve convenient and accurate collection and ensure accurate sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

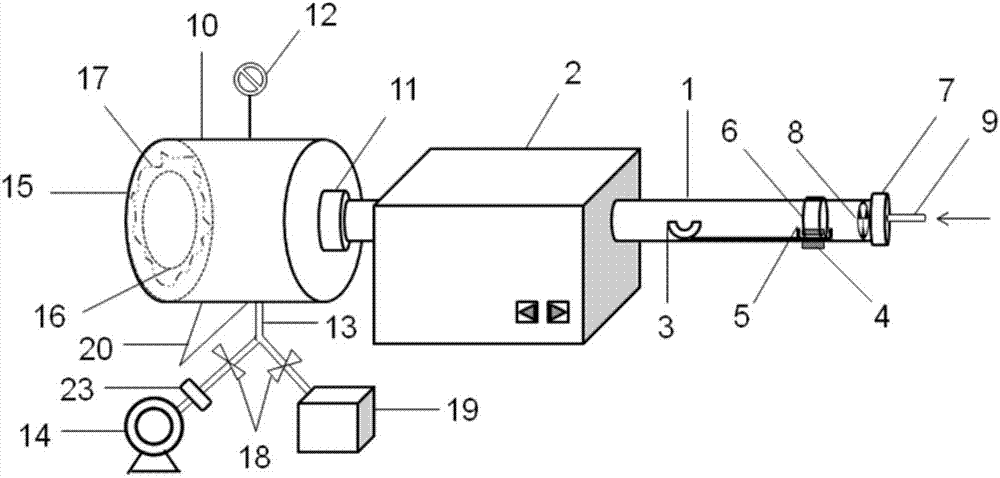

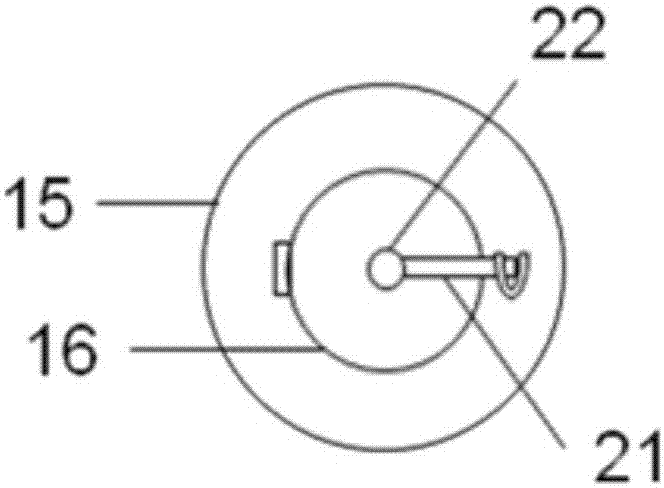

[0027] Such as figure 1 As shown, the material combustion experimental device for simulating a low-pressure environment in this embodiment includes a sample heating device and a pressure control device;

[0028] The sample heating device includes a quartz tube 1 and a tube furnace 2 sleeved outside the quartz tube 1; a sample pool 3 for loading the material to be tested is placed in the quartz tube 1; one end of the sample pool 3 is connected to a magnet pool for loading a magnetite 4 5; the distance between the sample pool 3 and the magnet pool 5 is not less than half the length of the tube furnace 2; the periphery of the sample pool 3 and the magnet pool 5 is raised to prevent the sample and the magnet stone 4 from moving during operation; the outside of the quartz tube 1 passes through the ring 6 fix a piece of magnetite 4, and the ring 6 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com