Patents

Literature

47results about How to "Stable output flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

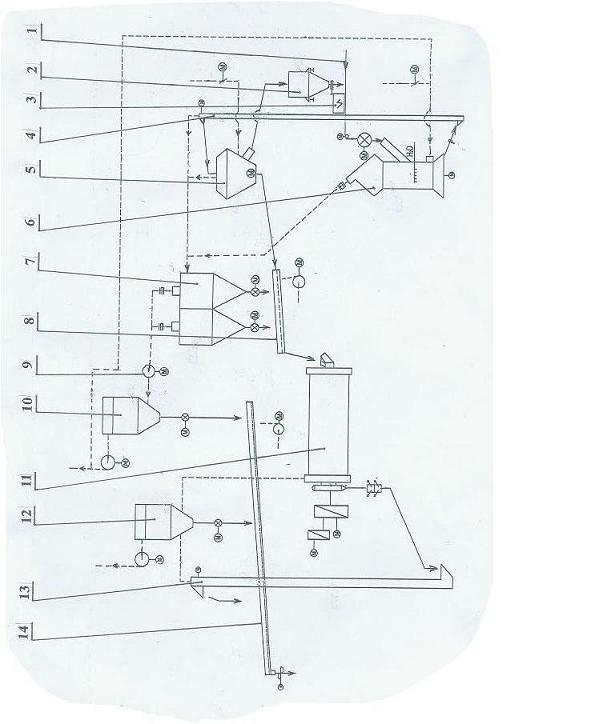

Single-compartment ball mill type cement vertical mill grinding device

InactiveCN102179285AIncrease cement productionShorten the lengthGrain treatmentsSingle compartmentBall mill

The invention discloses a single-compartment ball mill type cement vertical mill grinding device, which is mainly characterized in that: on the basis of the conventional mill consisting of a cement vertical mill and a ball mill, a multi-compartment ball mill is changed into a single-compartment fine grinding ball mill, and a coarse powder circulating device is arranged, wherein the coarse powder circulating device is connected in series between the discharge hole of the cement vertical mill and the feeding hole of the single-compartment fine grinding ball mill. Aggregates with large particles output by the cement vertical mill can be returned to the input end of the cement vertical mill, and enter the vertical mill to be reground, so that outer circulation is formed; coarse materials are prevented from entering the ball mill, the ball mill can be the single-compartment fine grinding ball mill directly, raw materials entering the cement vertical mill have stable flow rate, and problems that the cement vertical mill shocks and the like are solved; and the single-compartment ball mill type cement vertical mill grinding device can further improve the cement grinding efficiency, reduce grinding electricity consumption, easily control the particles of fine powder and ensure good grading of the particles of cement products.

Owner:JIANGSU LINGYANG CEMENT ENG TECH

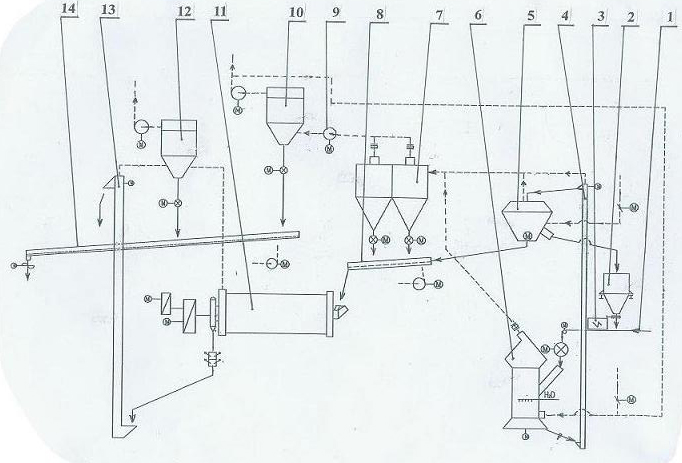

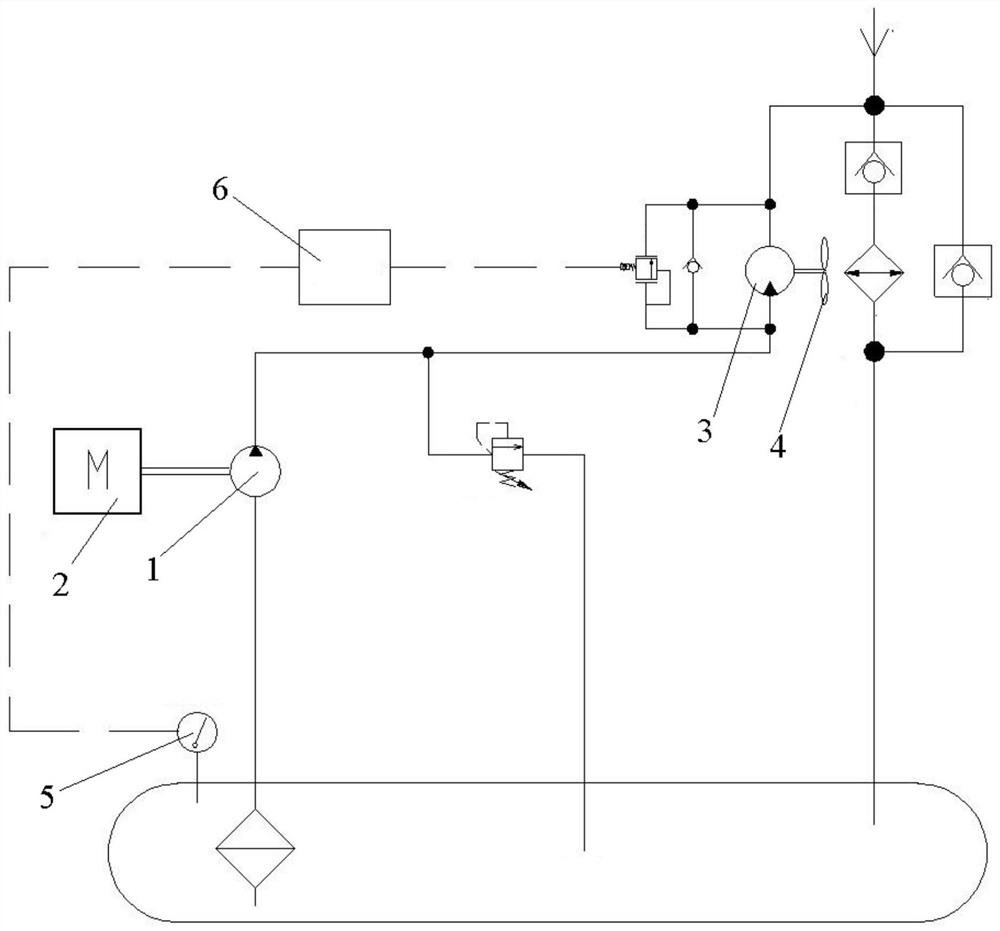

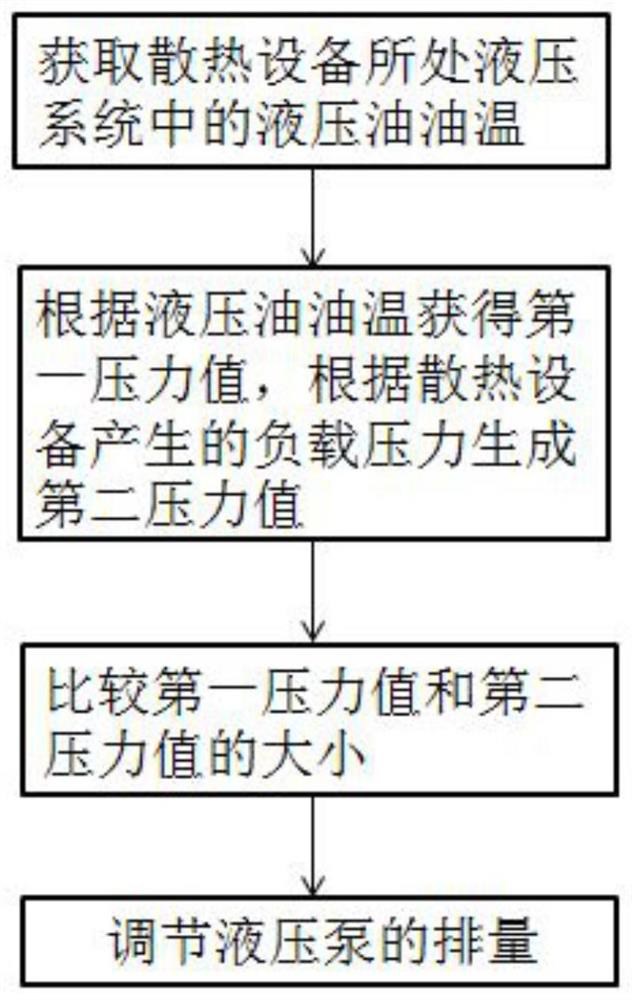

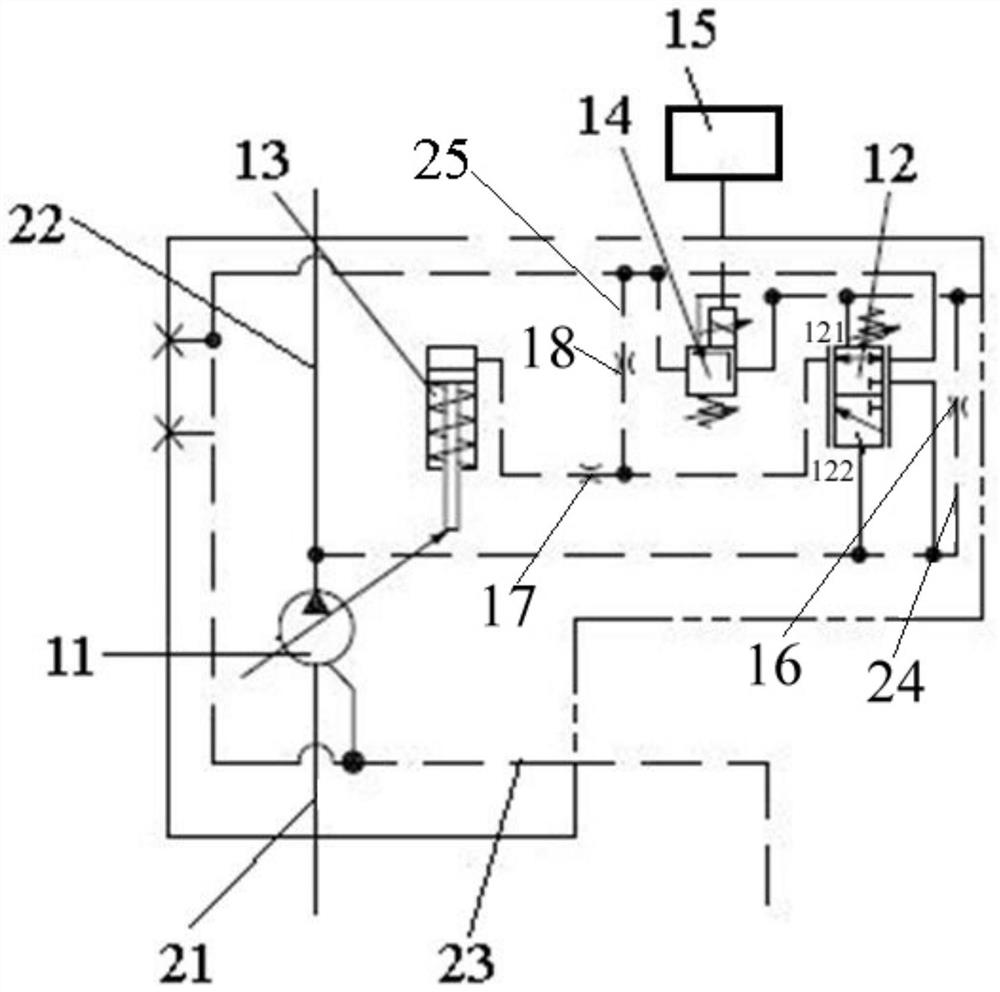

Pressure compensation type hydraulic pump, rotating speed control system, rotating speed control method and engineering machinery

PendingCN112128178AStable speedStable jobServomotor componentsServomotorsSpeed control systemControl system

The invention relates to engineering machinery, and specifically discloses a pressure compensation control type hydraulic pump. The hydraulic pump comprises an electric proportional pressure compensator, a hydraulic pump, a hydraulic control reversing valve and a servo piston, the electric proportional pressure compensator can be electrically connected with a controller, a first hydraulic controlport of the hydraulic control reversing valve is connected with an internal oil drainage oil way through the electric proportional pressure compensator, the first hydraulic control port is connected to an internal output oil way through a hydraulic control oil-inlet oil way provided with a first throttling valve, a second hydraulic control port of the hydraulic control reversing valve is connectedwith the internal output oil way, and the pressure difference between the opening pressure of the electric proportional pressure compensator and the pressure of an oil outlet of the hydraulic pump can drive the hydraulic control reversing valve to reverse. In this way, a rodless cavity of the servo piston selectively communicates with the internal output oil way or the internal oil drainage oil way. In addition, the invention further discloses a rotating speed control method, a rotating speed control system and engineering machinery. According to the hydraulic pump, the output flow of the hydraulic pump can be stabilized at a required value.

Owner:ZOOMLION HEAVY IND CO LTD +1

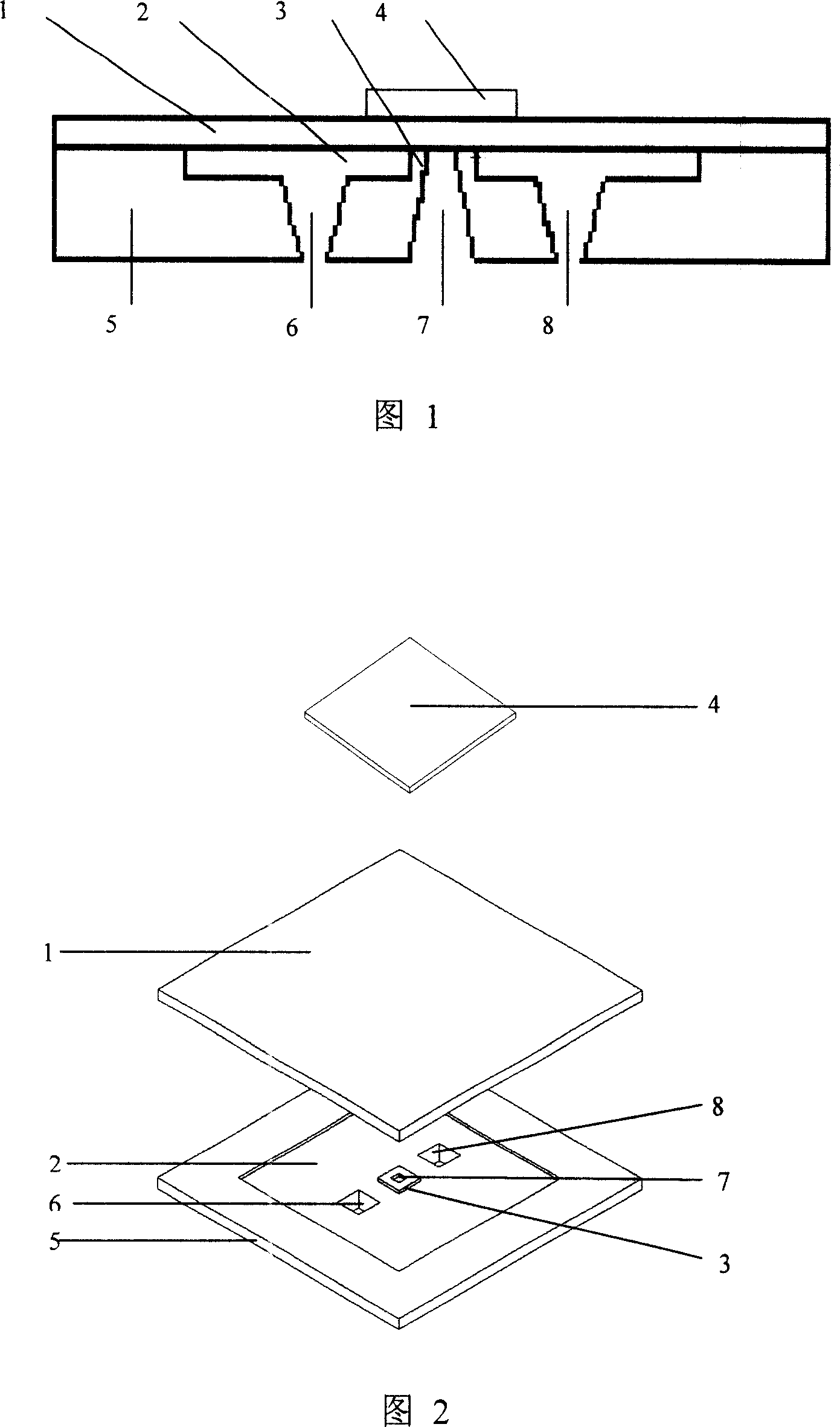

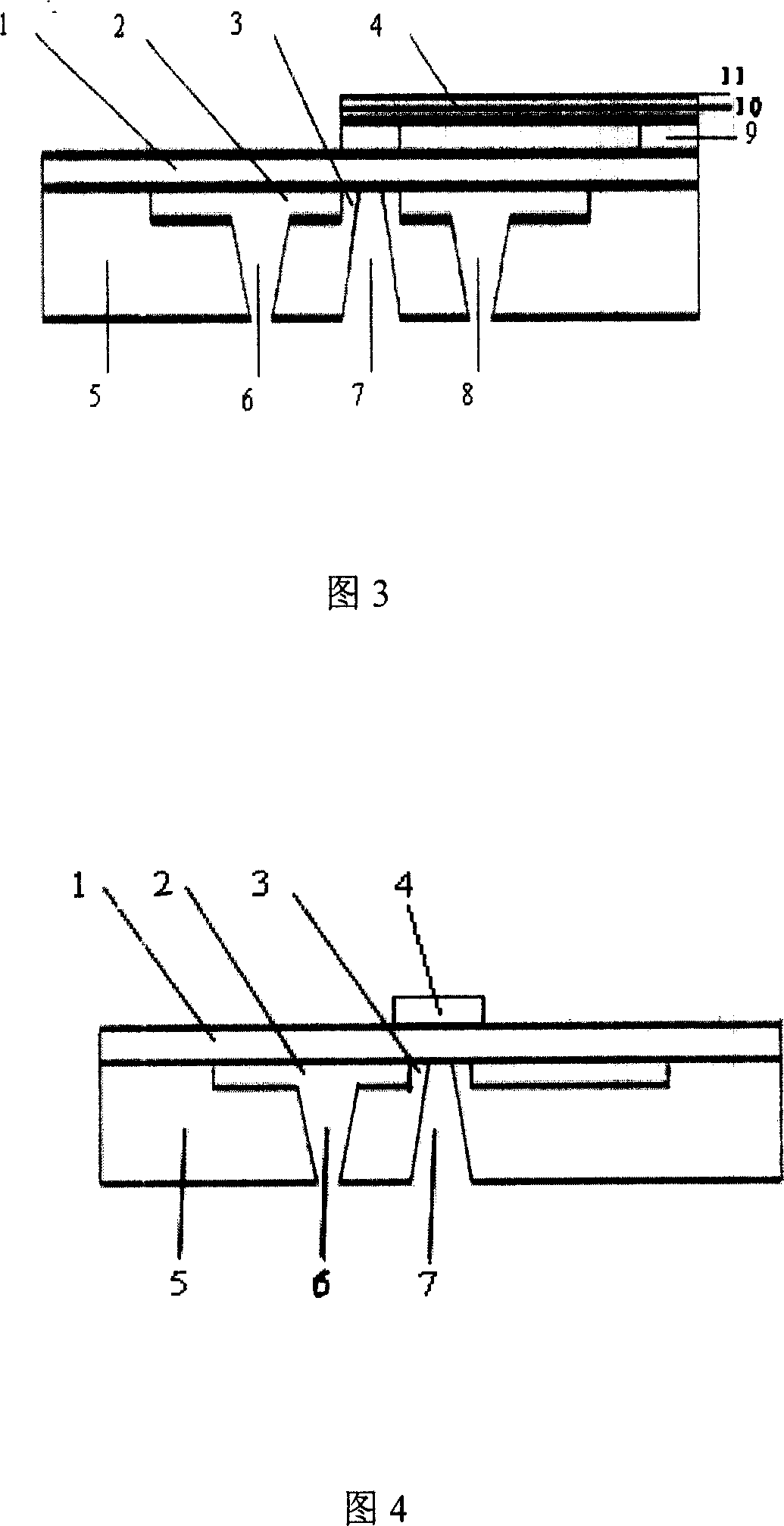

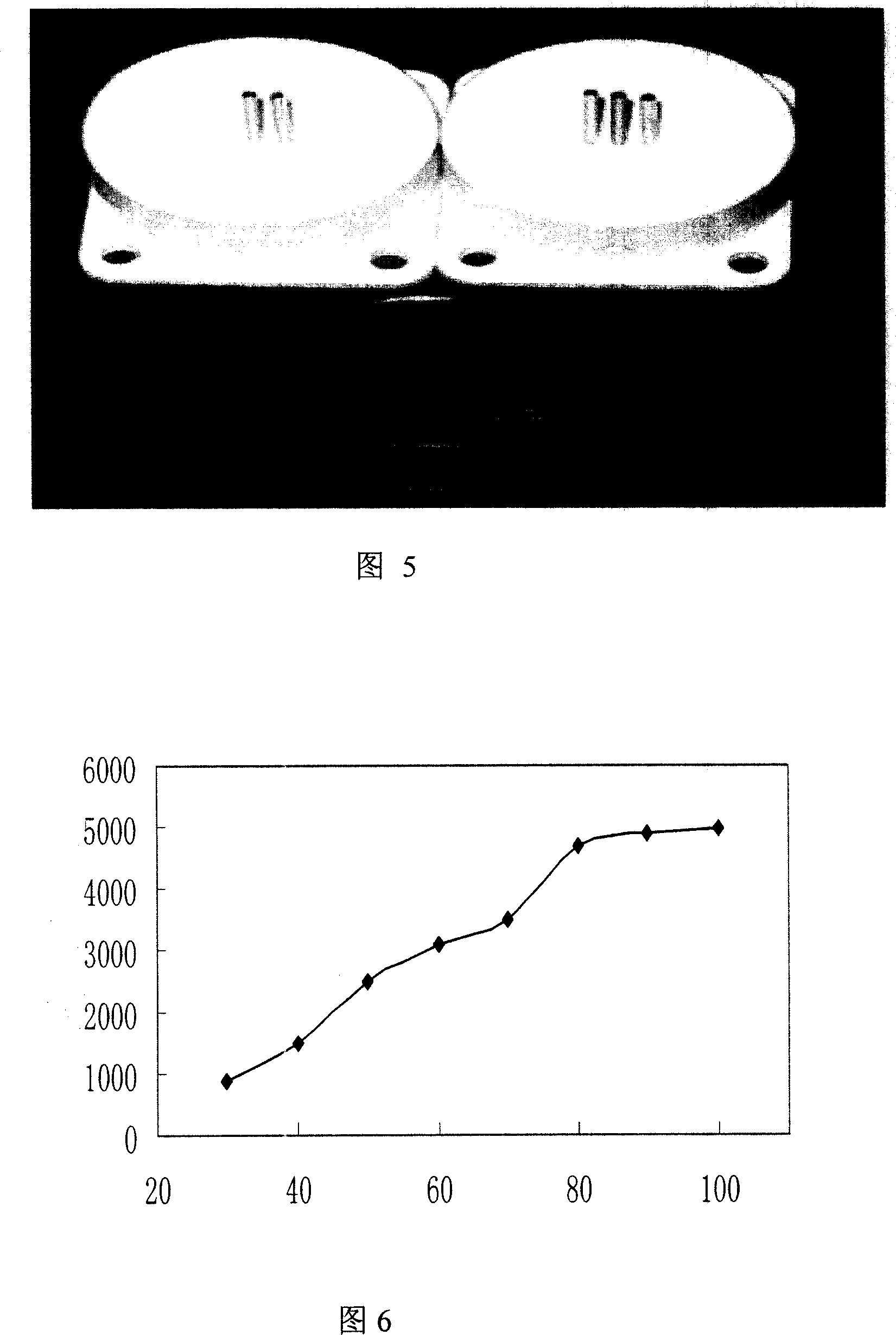

Mini self-priming pump

InactiveCN101122286AHave diversityExtended service lifeFlexible member pumpsPositive-displacement liquid enginesHigh volume manufacturingPump chamber

The invention discloses a novel mini pump capable of self-priming, and effectively settles the problems of periodical fluctuation, unstable flow, failure to self-prim, inapplicability to gas working substances, and so on. With the pump, the output flow is more stable and capable of continuous adjusting and complete self-priming, and no sample injection is required. The pump is not only applicable to liquid working substances, but also applicable to gas working substances, so the using scope of the mini pump is enlarged and the usable life and working stability of the mini pump is increased. The novel mini pump is simple in the structure. The pump comprises a lower pump plate, an upper pump plate, a drive, a pump chamber, a valve seat, a first cone diffusion pipe, a cone contraction pipe, and a second cone diffusion pipe, and is provided with the advantages of the quick response, the broad drive frequency, the strong controllability, the low power consumption, the long usable life, the small dimension, the simple manufacture technique, the low cost, and so on. In addition, the invention can be manufactured by using the technique of micro-processing and materials compatible with the micro mechanical technology, and can be integrated easily with other micro tests, micro-controlled elements and so on. The invention is suitable for mass production and is provided with a very wide application prospect.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

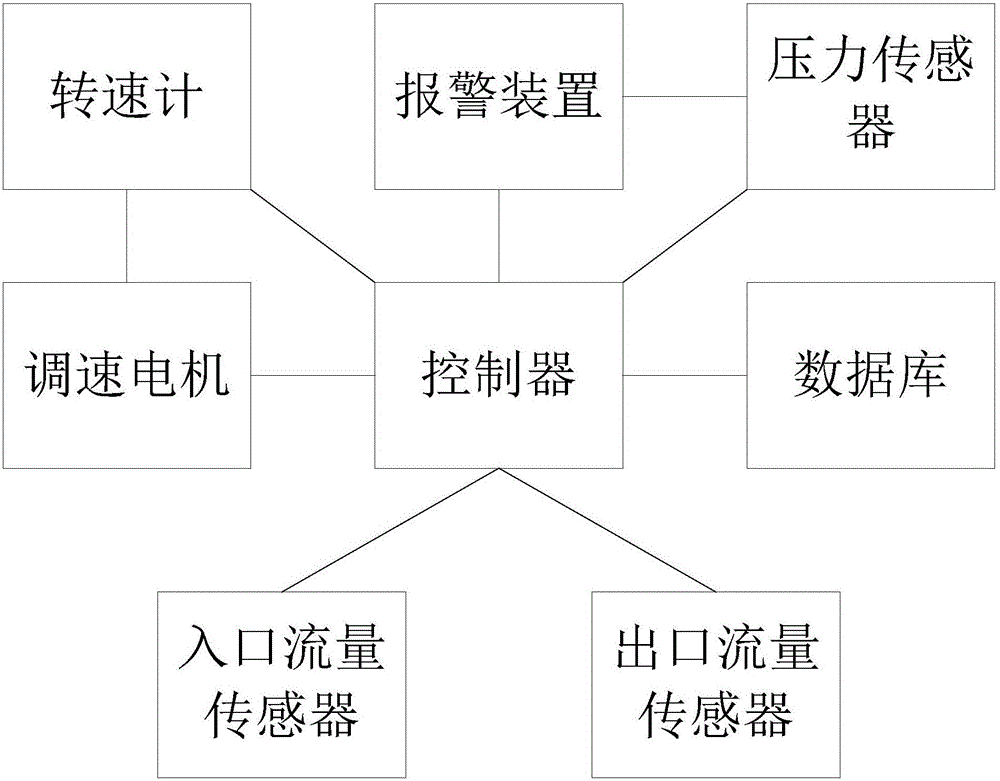

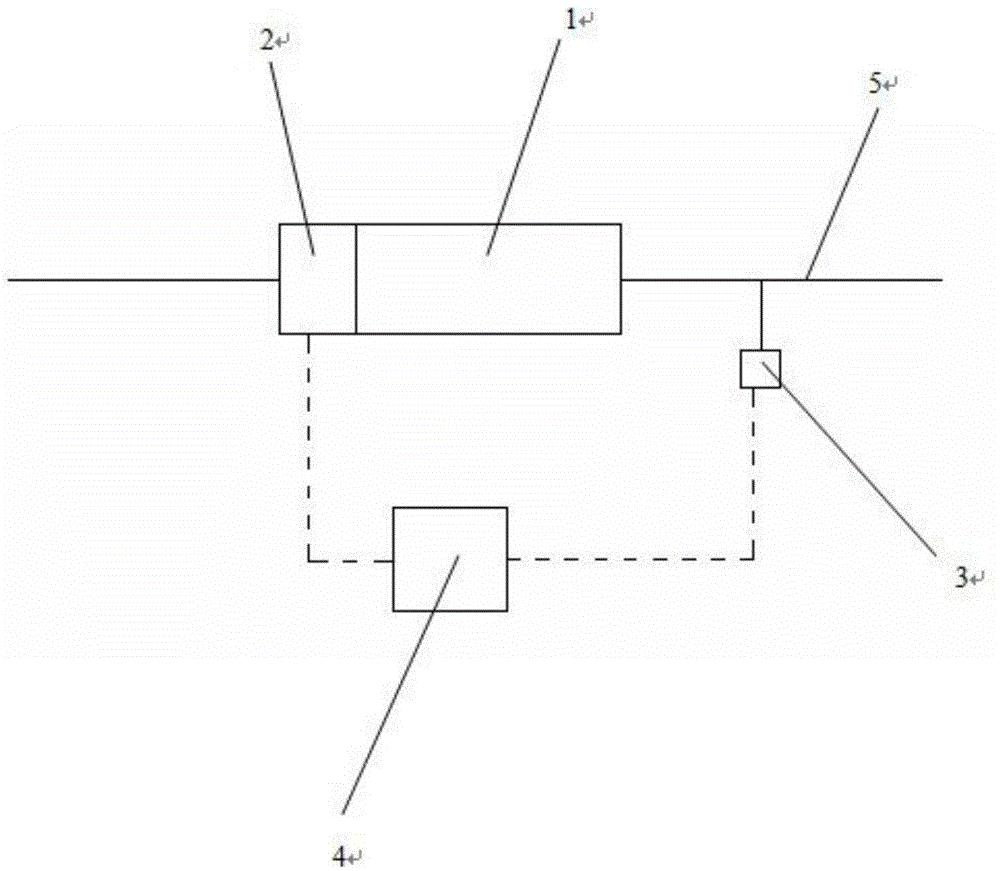

Screw pump flow feedback speed regulating system

InactiveCN106762617AStable output flowWith self-test functionMachines/enginesPump controlLiquid viscosityControl system

The invention discloses a screw pump flow feedback speed regulating system which comprises an adjustable speed motor of a screw pump and also comprises a controller connected with the adjustable speed motor, and the controller is also connected with an outlet flow sensor and an alarm device; in the system, a closed-loop control system is formed with the adjustable speed motor as an executor, the outlet flow sensor as a sensor and the controller as a controller, the aim of the system is control of flow of the screw pump by controlling the rotating speed of the adjustable speed motor, and the problems that the flow of the screw pump can fluctuate sometimes due to variation of liquid viscosity when the screw pump is adopted for sucking and discharging liquid and the screw pump is hard to operate when stable flow is required are solved. The screw pump flow feedback speed regulating system disclosed by the invention has the advantages that the feedback control system is adopted, stable output flow of the screw pump is guaranteed, and the screw pump flow feedback speed regulating system has multiple self-checking functions and high stability.

Owner:四川凯创机电设备有限公司

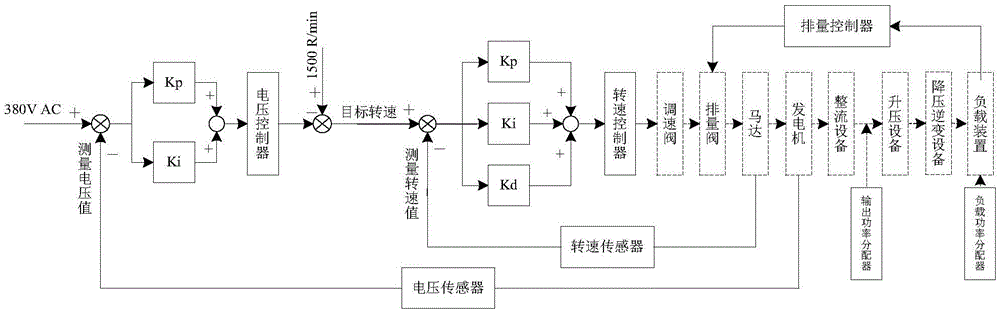

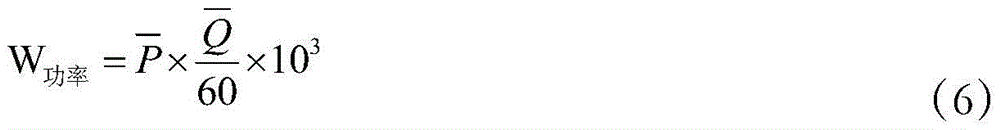

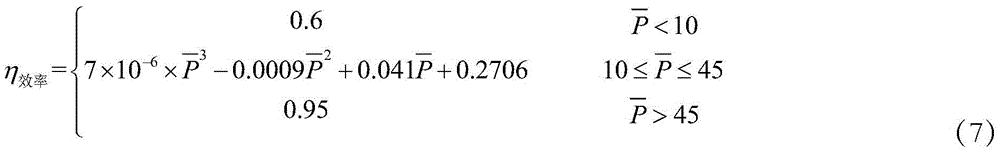

Energy steady output control system applicable to hydraulic wave power generation device

InactiveCN105626366AStable outputStable output flowMachines/enginesSafety/regulatory devicesWave power generationControl system

The invention discloses an energy steady output control system applicable to a hydraulic wave power generation device. Firstly, the opening degree of a speed regulating valve is adjusted through voltage and speed dual-loop PID control, the fact that a first level of hydraulic energy output flow is stable is guaranteed, and the situation that output of electric energy of the whole wave power generation device is instable due to instability of the first level of hydraulic energy output flow is avoided; meanwhile, voltage and rotating speed of a power generator are stabilized to be nearby target values; secondly, power which rectifier equipment can output and load-bearing capacity (that is to say load power) of a load device are pre-distributed according to energy which the wave power generation device already absorbs, so that the effect that the already absorbed energy is fully utilized is guaranteed, and meanwhile balance of output energy and a load is achieved; and thirdly, the opening degree of a discharge capacity valve is adjusted according to actual load power, the load-bearing capacity of the wave power generation device is further adjusted, and the optimum match of the already absorbed energy, the output energy and the load is achieved.

Owner:710TH RES INST OF CHINA SHIPBUILDING IND CORP

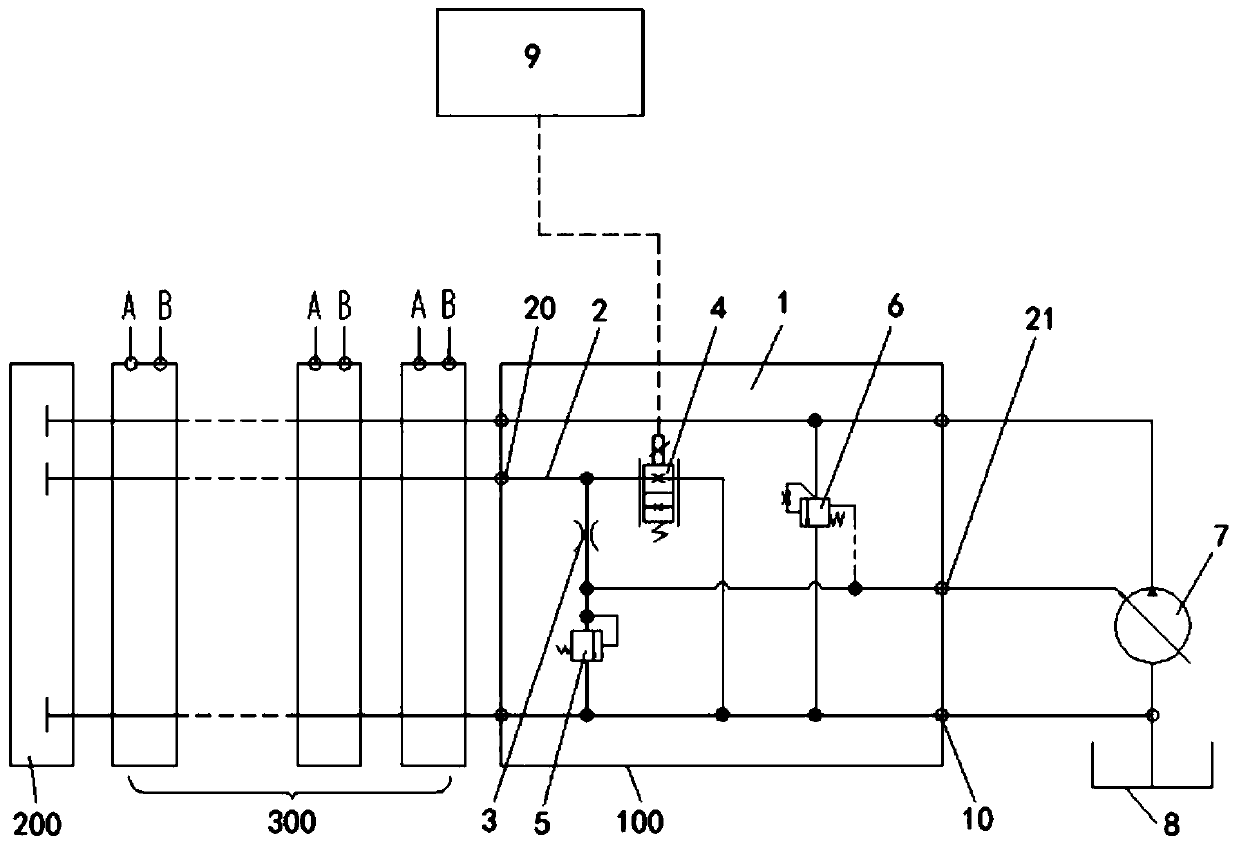

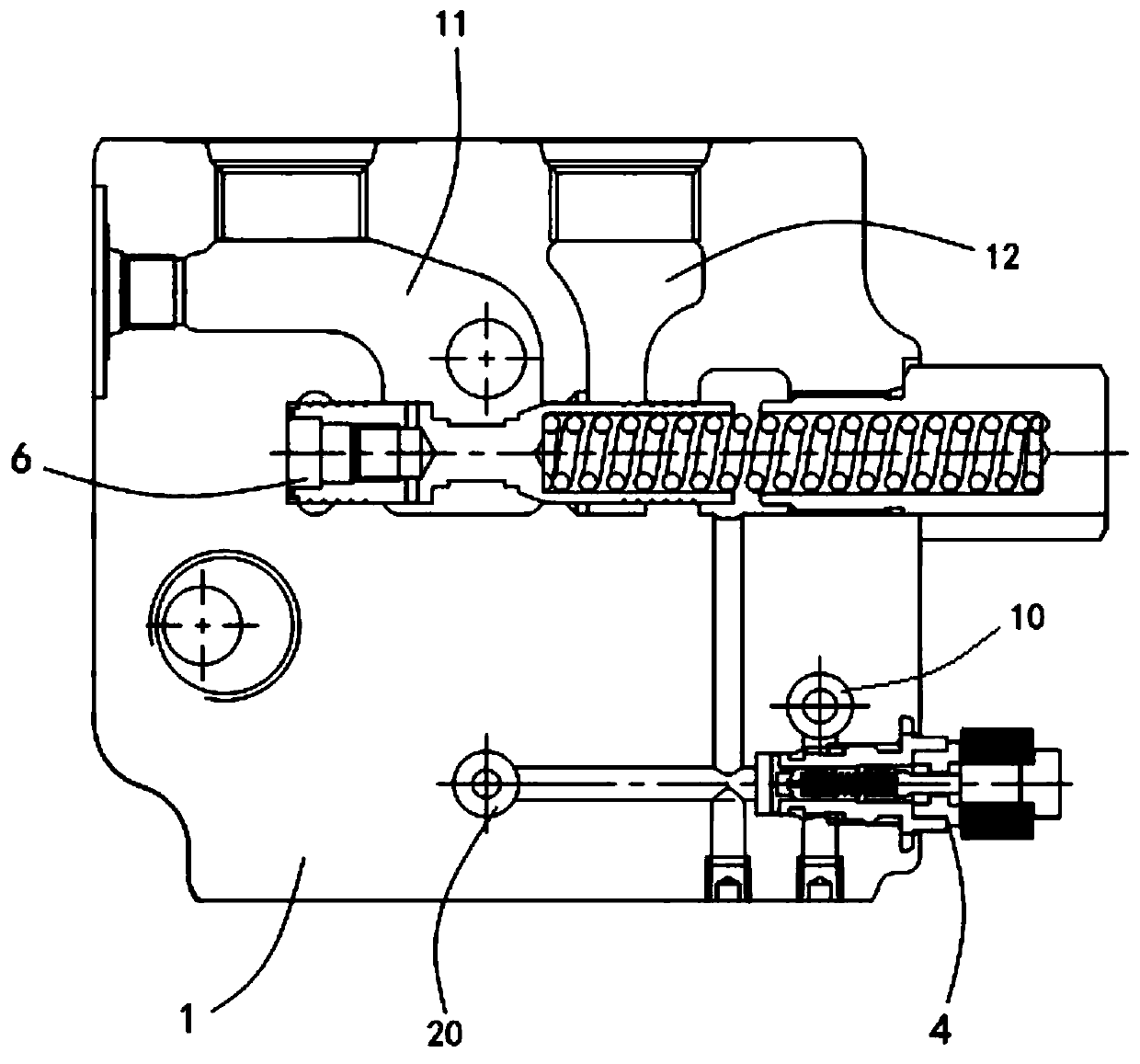

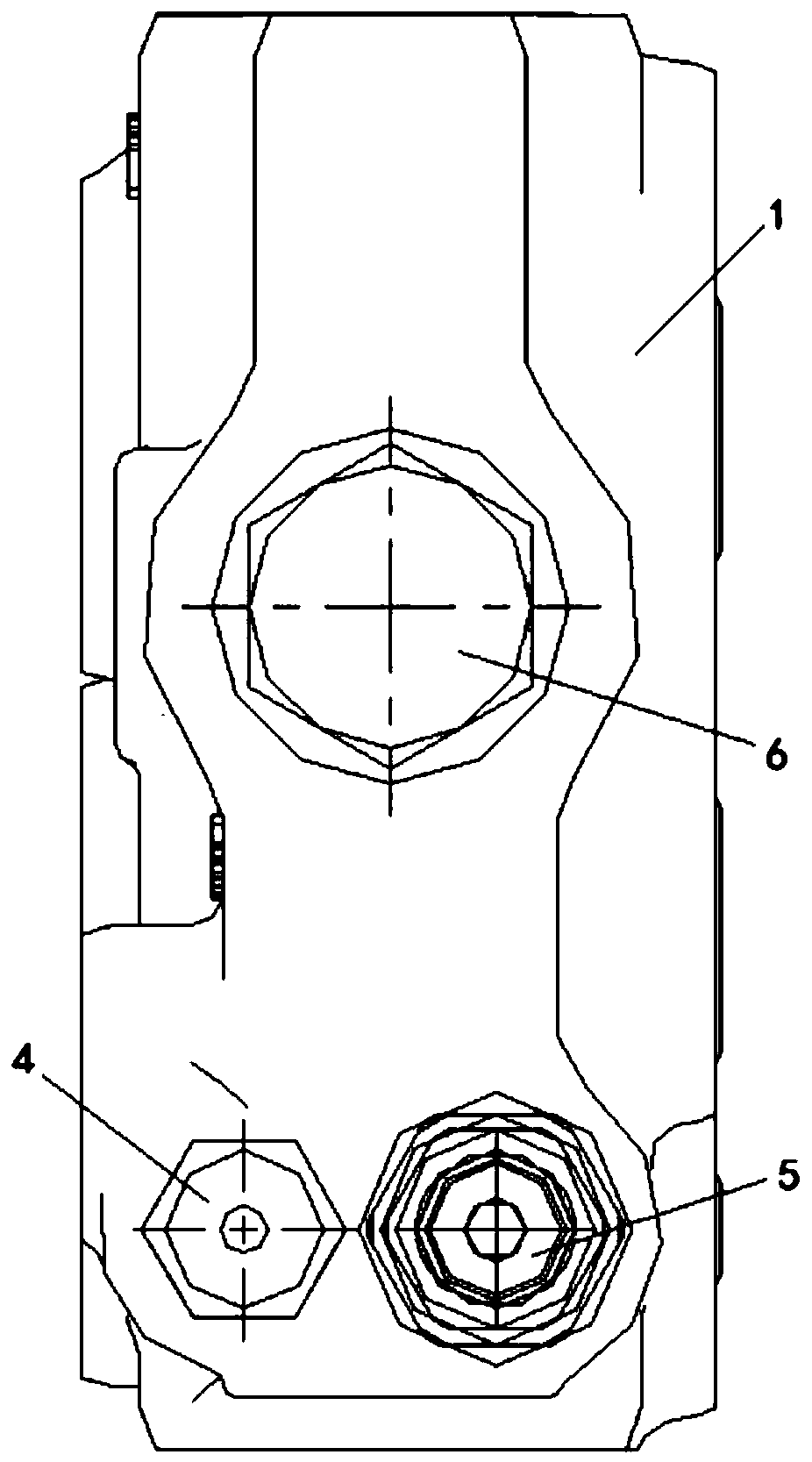

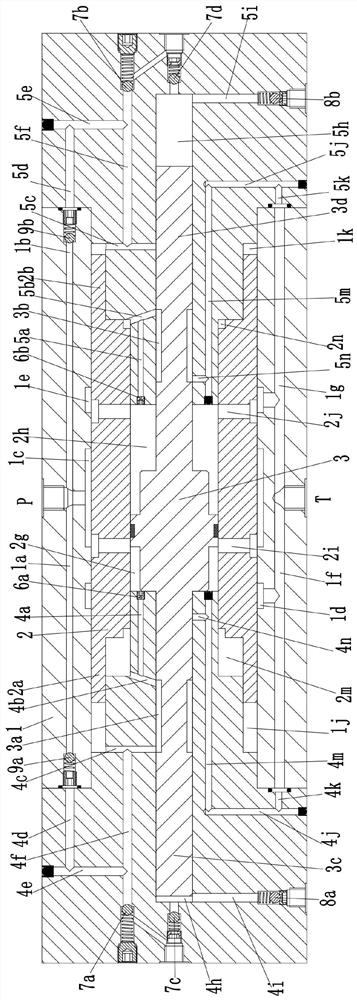

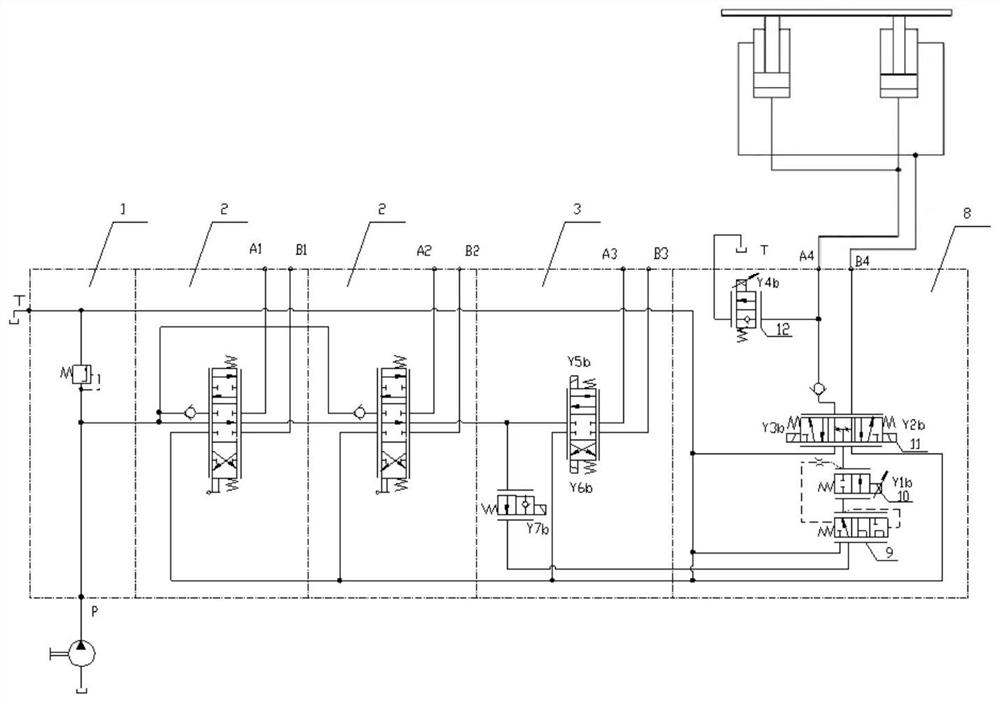

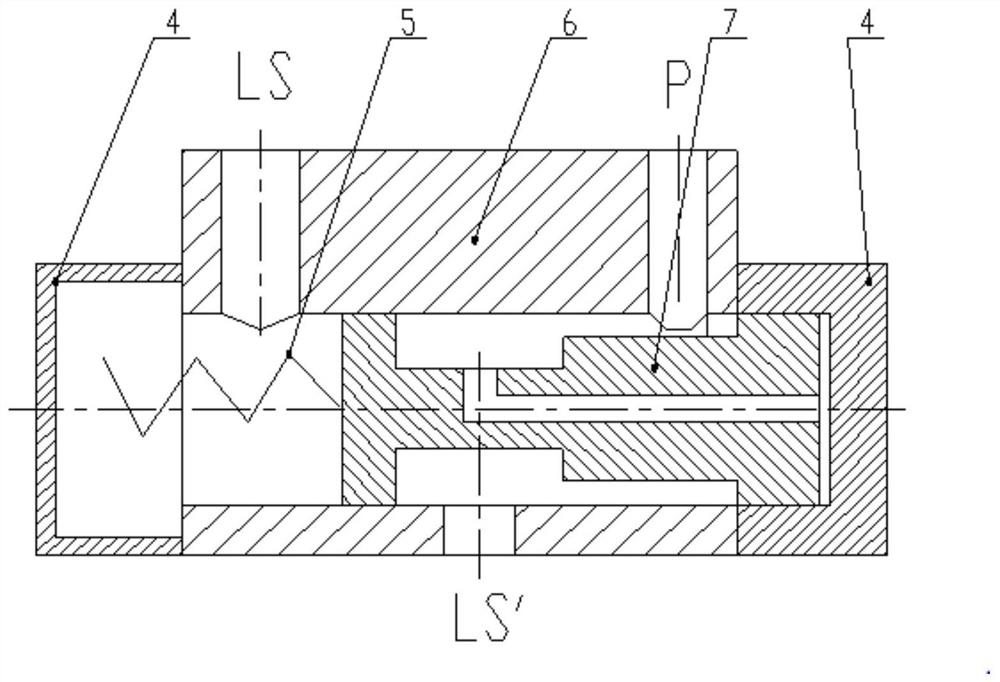

Combined multi-way valve and combined multi-way valve control system

ActiveCN111156213ASmooth movementMovement coordinationServomotor componentsServomotorsPressure transmissionControl system

A combined multi-way valve comprises a head unit, a tail unit and a plurality of sets of working units. Each working unit is provided with a set of paired working oil port A and working oil port B. The head unit comprises a valve body, a valve element and a feedback channel. A first cavity and a second cavity are formed in the valve body. A first feedback port of the feedback channel selectively communicates with a set of working oil port A and working oil port B, and a second feedback port of the feedback channel is connected with an external variable pump. A throttle valve is mounted on thefeedback channel to transmit load feedback pressure of each working oil port A or working oil port B to the external variable pump. An electric proportional flow valve is mounted between the first feedback channel and an oil return port of the valve body to adjust load feedback pressure in the feedback channel. The invention further provides a combined multi-way valve control system. According tothe combined multi-way valve and the combined multi-way valve control system, the electric proportional flow valve is used to stabilize the load feedback pressure in the feedback channel in the combined multi-way valve, so that output flow of the external variable pump is stable, and it is ensured that an executing mechanism is harmony in action, stable and good in operating performance.

Owner:中联重科土方机械有限公司

Resin quantitative replacement device

InactiveCN101524738ARealize equivalent replacementPrevent oxidationFoundry mouldsMould handling/dressing devicesFuel tankPlunger pump

The invention provides a resin quantitative replacement device which comprises a speed regulating motor, a plunger pump and a replacement tank, wherein a rubber bag is arranged in the replacement tank, the upper end of the replacement tank is provided with a feeding pipe which extends into the rubber bag, a valve is arranged on the feeding pipe, the upper side wall of the replacement tank is provided with an oil filling hole, the side wall of the replacement tank is provided with an upper oil drain pipe and a lower oil drain pipe, valves are arranged on the oil drain pipes, the bottom of the rubber bag is provided with a resin output hole, the speed regulating motor is connected with the plunger pump by a crank, an oil filling hole of the plunger pump is connected with a hydraulic oil tank, and an oil outlet of the plunger pump is connected with the oil filling hole of the replacement tank. The invention outputs the resin by a hydraulic oil extruding method and can realize the quantitative replacement of hydraulic oil with the resin, the resin does not in direct contact with the pump, which radically avoid the damage of the pump by the resin, the pump can stably operate and does not need to be cleaned and maintained, the resin output flow is not influenced by environmental temperature to ensure the stable resin output flow, and meanwhile, the seal type resin output is adopted to prevent resin oxygenation.

Owner:冯新林

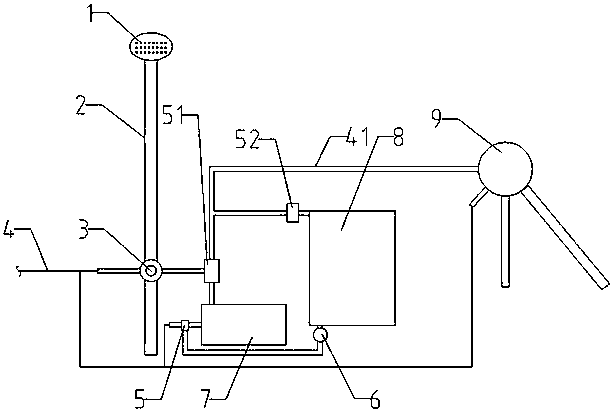

Energy-saving shower device

ActiveCN108534374AGood technical effectAvoid the problem of high energy consumption for heatingSolar heating energyBathsSolar waterEngineering

The invention discloses an energy-saving shower device which comprises a shower, a main three-way valve, a branch three-way valve, an insulation circulation valve, a water injection pump, a heater, aninsulation tank and a solar water heater; the shower is composed of a sprinkler, a supporting rod and a shower valve; one end of the shower valve is connected with a cold water pipe; two ports of themain three-way valve are connected with the shower valve and the heater respectively, and the other port of the main three-way valve is connected with the insulation circulation valve and the solar water heater at the same time; the insulation circulation valve is connected with the insulation tank; the heater is connected with one end of the branch three-way valve, and the other ends of the branch three-way valve are connected with the cold water pipe and the water injection pump respectively; the water injection pump is connected with the insulation tank; each of the heater, the insulationtank and the solar water heater is provided with a temperature sensor; and the temperature sensors and the heater are connected with a controller. The energy-saving shower device provided by the invention avoids the problem that heating consumes a great quantity of energy by using the water heater all the time and saves the energy.

Owner:李雨露

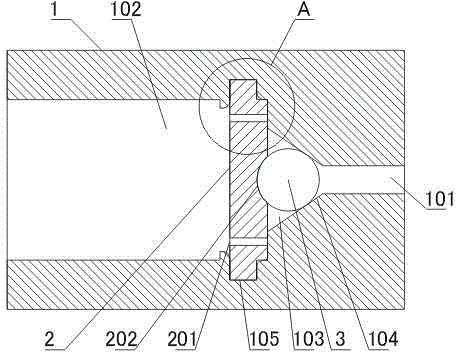

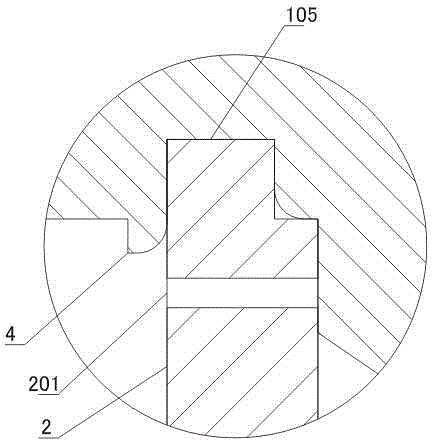

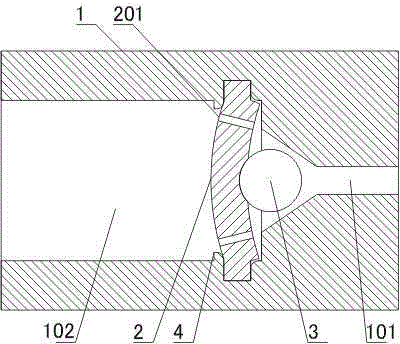

Mini-type pressure reduction pipe

InactiveCN104132170AReduce volumeSimple structureEqualizing valvesSafety valvesEngineeringHigh pressure

The invention discloses a mini-type pressure reduction pipe. The mini-type pressure reduction pipe comprises a pipe body, a rubber sheet, a containing cavity and a ball sealer, wherein the two ends of the pipe body are provided with connection threads, the space inside the pipe body is composed of a high pressure cavity and a low pressure cavity, the inner diameter of the high pressure cavity is smaller than that of the low pressure cavity, the rubber sheet is arranged inside the low pressure cavity and is connected with the inner surface of the low pressure cavity, the rubber sheet makes contact with the end portion of the high pressure cavity, the position where the rubber sheet makes contact with the end portion of the high pressure cavity is evenly provided with multiple vent holes, a circular arc groove is formed in the center of the rubber sheet, the containing cavity is arranged at one end, close to the rubber sheet, of the high pressure cavity, the ball sealer is arranged inside the circular arc groove, and the ball sealer is compressed in the containing cavity by the rubber sheet and is tightly attached to the transition position of the containing cavity. The rubber sheet replaces a spring, so that the size of the pressure reduction pipe is reduced effectively.

Owner:CHENGDU GUOGUANG ELECTRONICS INSTR

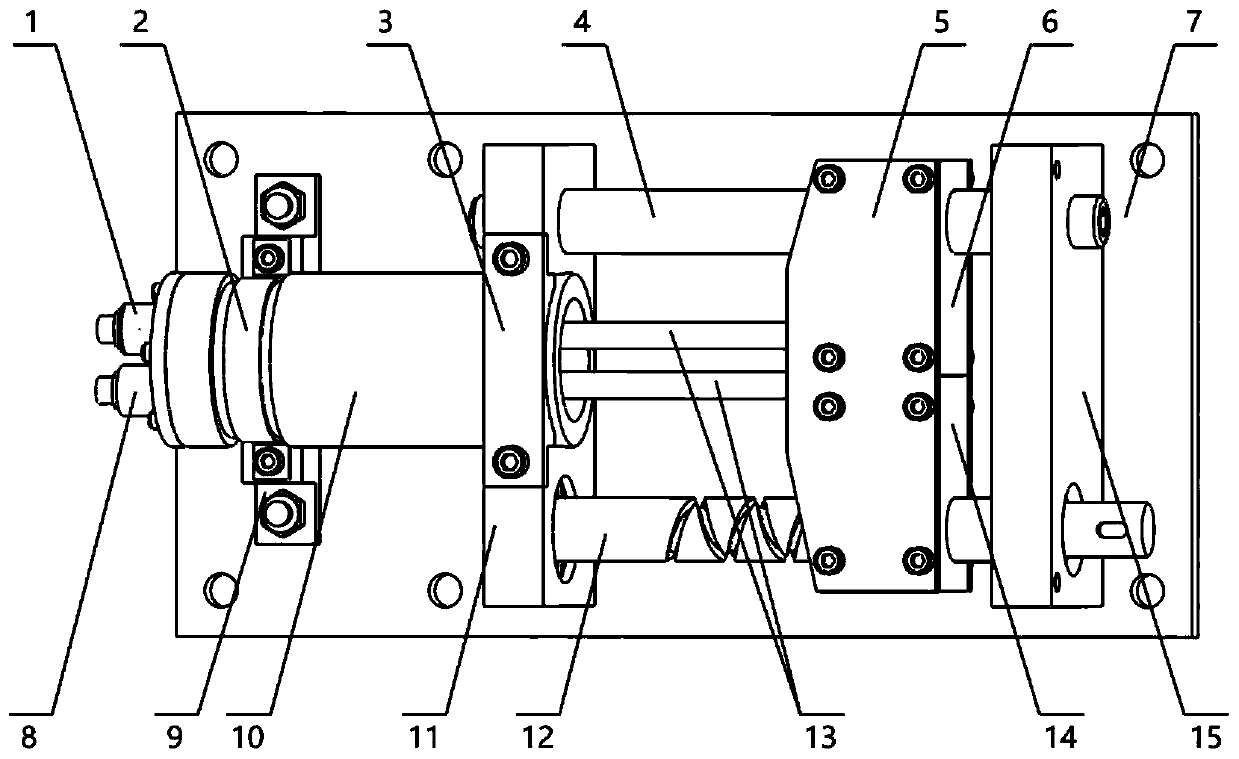

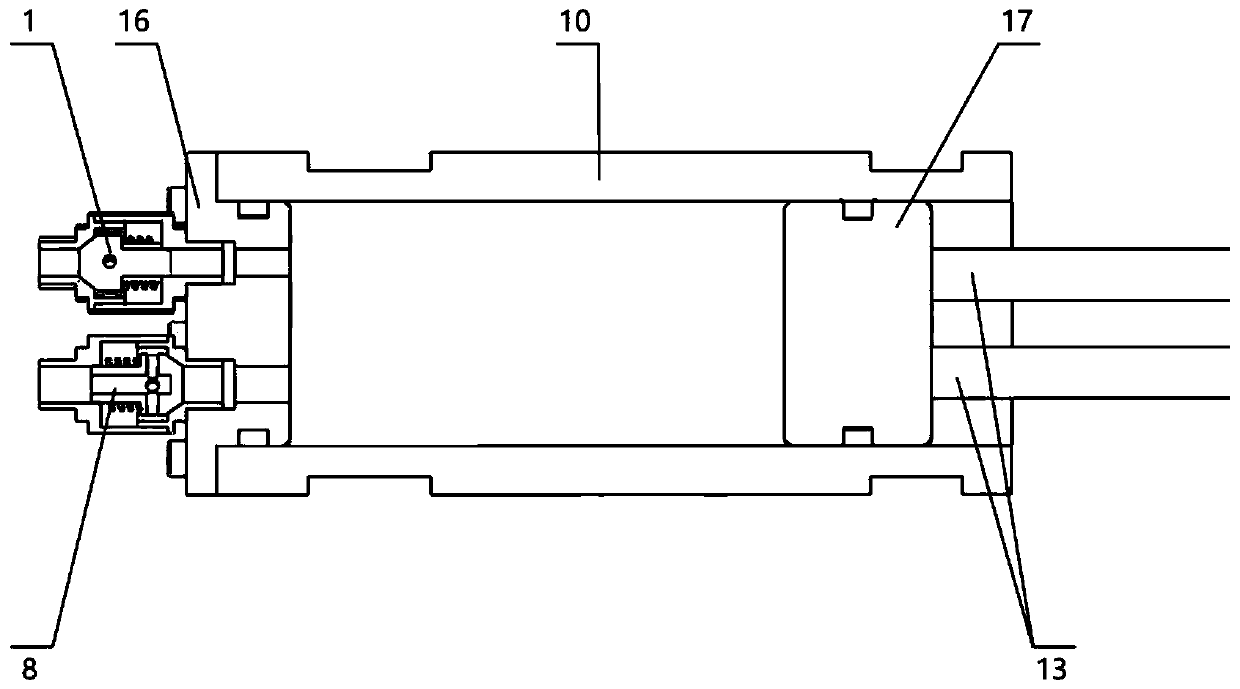

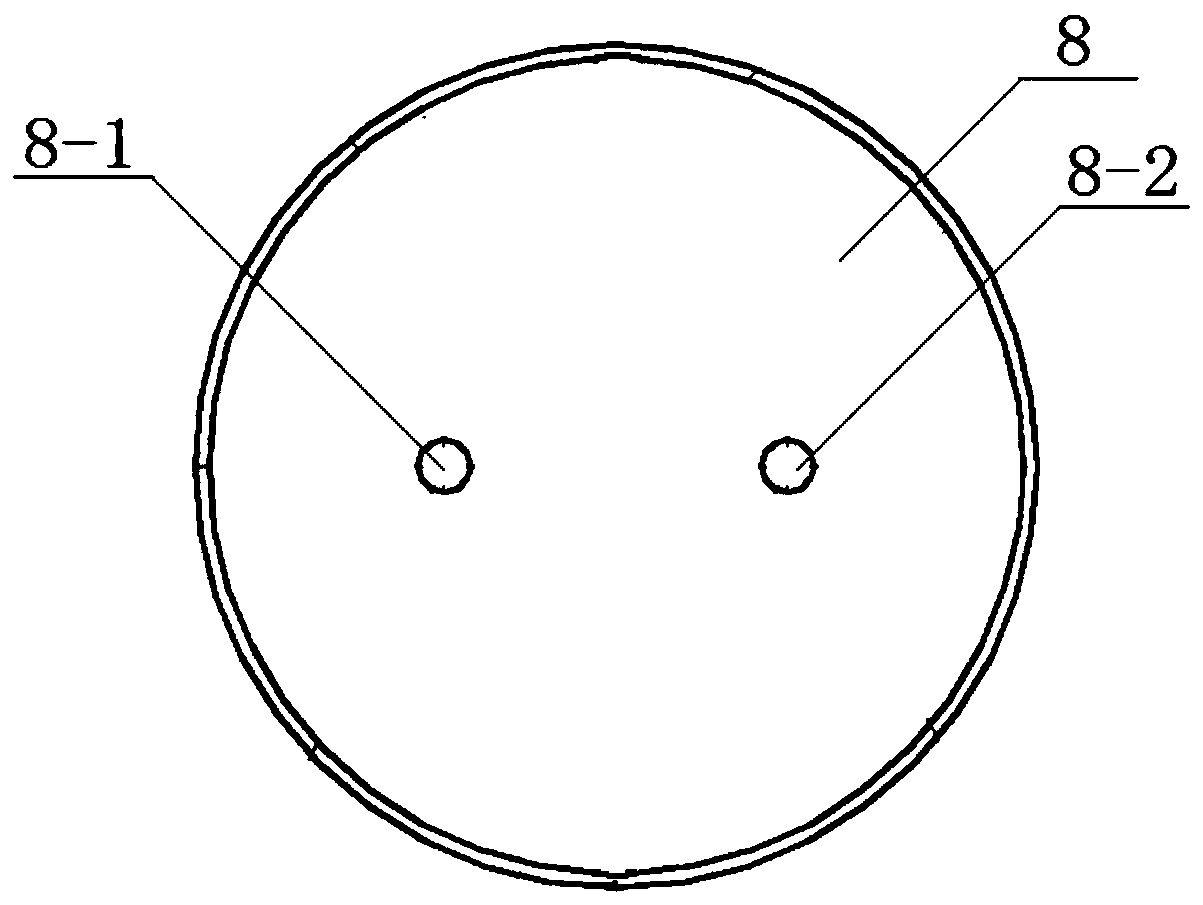

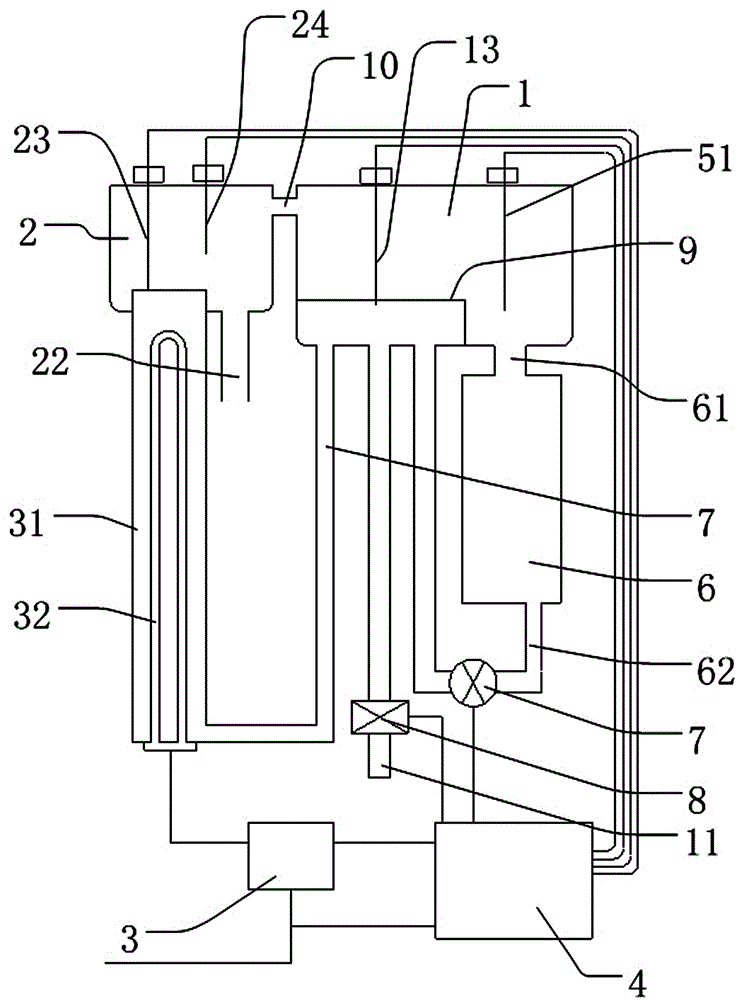

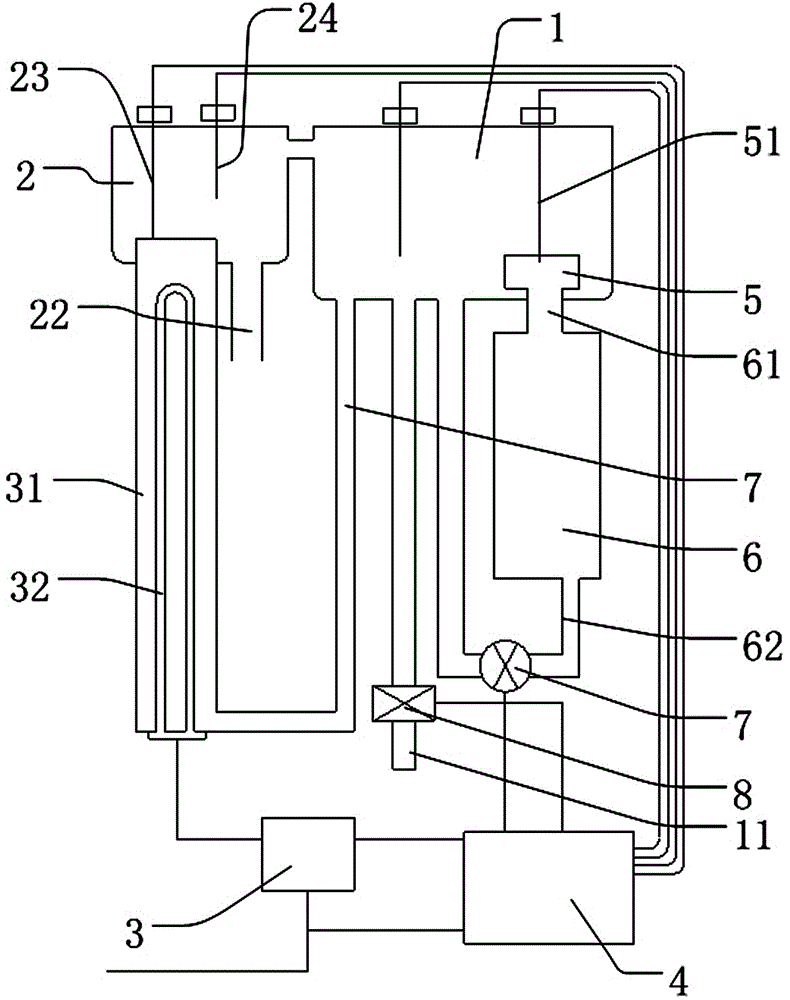

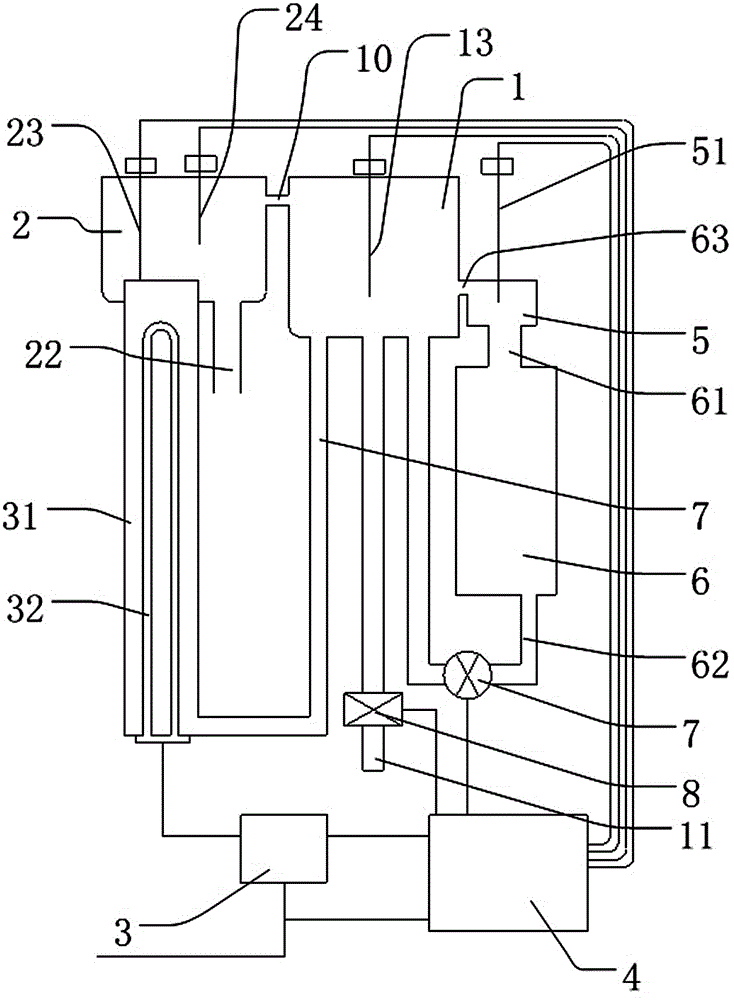

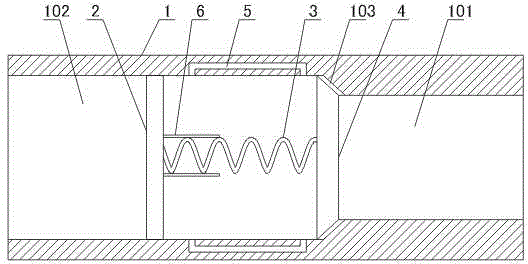

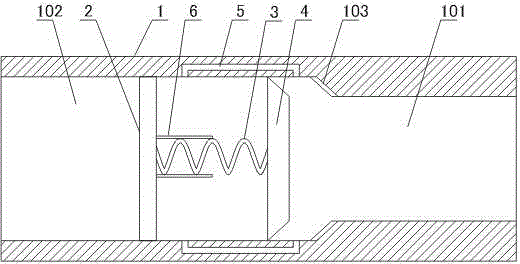

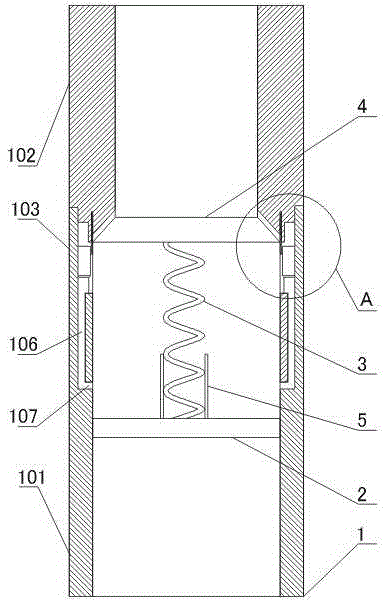

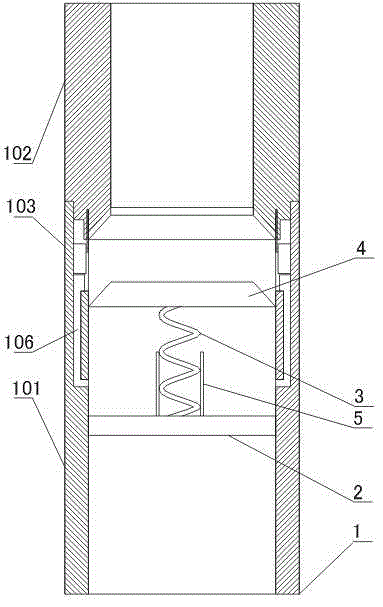

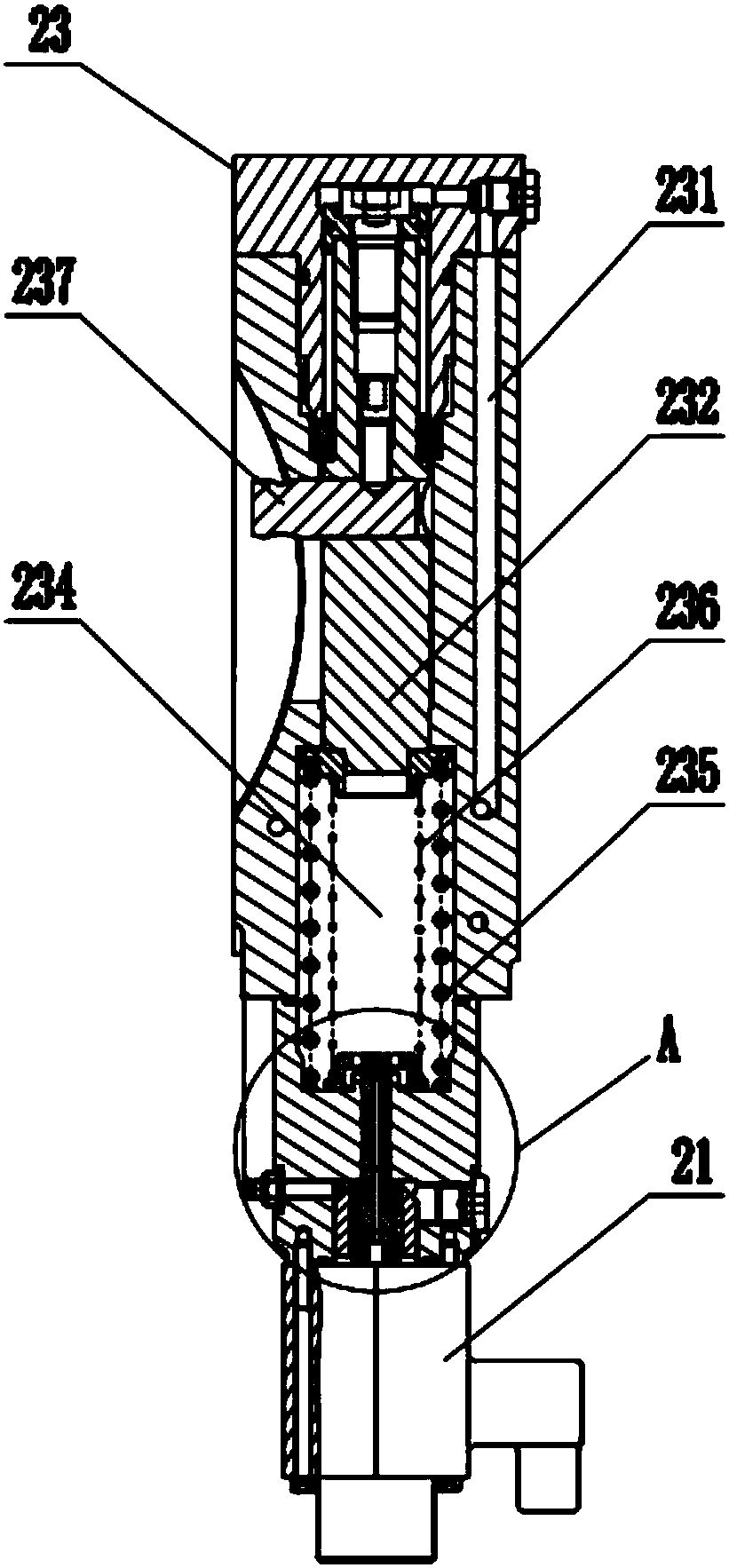

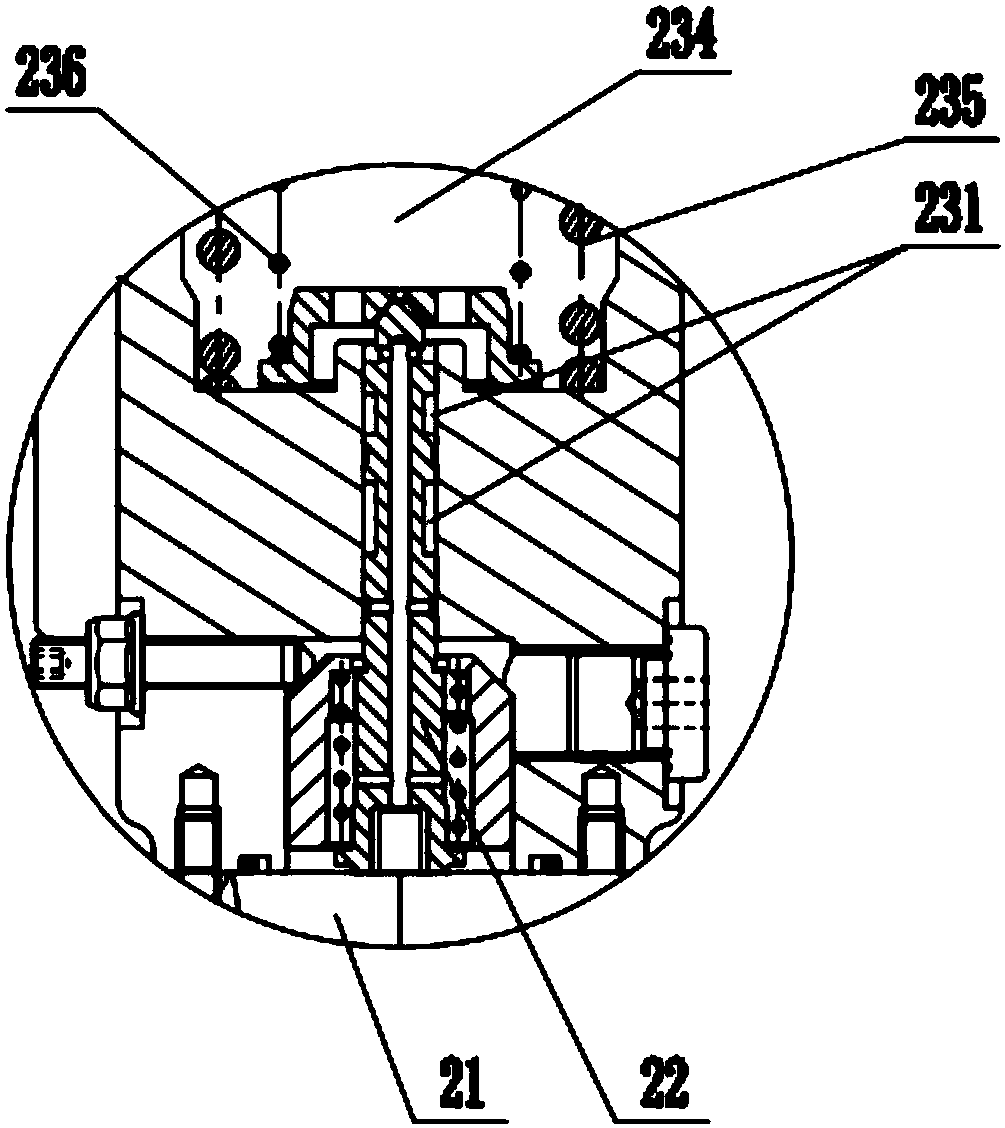

Quantitative pump special for in-situ filtration of deep sea microorganisms

InactiveCN110541799AReduce RPM requirementsStable output flowPositive displacement pump componentsFlexible member pumpsMicroorganismFiltration

The invention relates to a pump, in particular to a quantitative pump special for in-situ filtration of deep sea microorganisms. The quantitative pump comprises a pump body and a base, wherein a frontretainer and a rear retainer are oppositely arranged on the end surface of the base, and the top and bottom ends of the front retainer and the top and bottom ends of the rear retainer are connected with reciprocating lead screws through linear guide rods which are parallel to each other; guide rod sliding blocks are installed on the linear guide rods, lead screw sliding blocks are installed on the reciprocating lead screws, and the guide rod sliding blocks and the lead screw sliding blocks are connected into a whole through a sliding block fixing frame; the rear side of the pump body is fixedon the front retainer through a pump body fastening block; a piston is arranged in the pump body, wherein a blind hole is formed in the rear end of the piston and connected with one end of a connecting rod; and the other end of the connecting rod is connected with the sliding block fixing frame. According to the quantitative pump special for in-situ filtration of the deep sea microorganisms, long-time work at low flow can be realized; in addition, compared with an impeller mechanism of a traditional centrifugal pump, the requirement for rotating speed of an output shaft of an motor is lower;and finally, compared with a cam mechanism of a traditional plunger pump, the quantitative pump is stabler and more reliable.

Owner:ZHEJIANG UNIV

Gear pump

ActiveCN109737052AImprove reliabilityAvoid the inconvenience of adding lubricating fluidRotary piston pumpsRotary piston liquid enginesGear pumpDrive shaft

The invention discloses a gear pump. One side, away from a hollow gear cavity, of a lower pump cover is provided with a sealing cover used for sealing a first driving shaft bearing hole and a first driven shaft bearing hole, the lower pump cover is further provided with an oil drainage groove, the oil drainage groove is arranged along a straight line formed by connecting a circle center of the first driving shaft bearing hole and a circle center of the first driven shaft bearing hole, and the oil drainage groove communicates with the first driving shaft bearing hole and the first driven shaftbearing hole. According to the gear pump, a sealing channel formed by arranging the oil drainage groove and the sealing cover, so that cooling oil in the hollow gear cavity passes through the bearingholes when the cooling oil is discharged out of the outer side of the gear pump so as to provide lubrication for the bearing holes, the problem that a lubricating liquid is not convenient to add fromthe outer side of the gear pump to the bearing holes is avoided, so that the working reliability of the gear pump is improved.

Owner:CHINA PETROLEUM & CHEM CORP +2

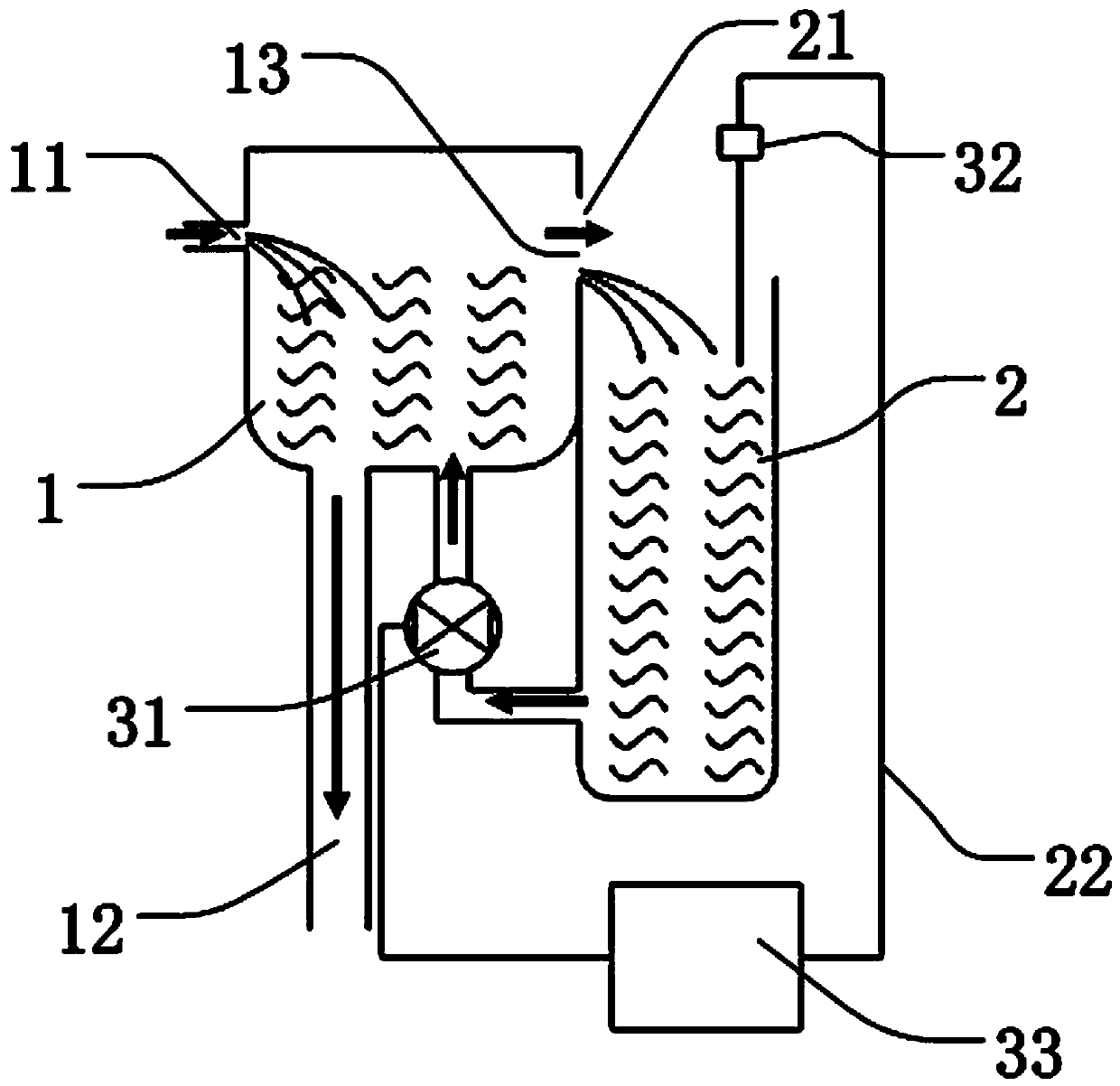

Water boiler with liquid level stabilizing function

The invention discloses a water boiler with a liquid level stabilizing function. The water boiler comprises a cold water tank, a boiled water tank and a heating pipe, a heater is arranged in the heating pipe, a water inlet valve is arranged on a water inlet pipe of the cold water tank, a water drain valve is arranged on a water drain pipe of the boiled water tank, the water boiler further comprises a driving unit, a control unit and a slow flow cavity, the control unit is electrically connected with the driving unit, the slow flow cavity is located below the cold water tank and used for forming a cold water circulation, the slow flow cavity is provided with a slow flow water inlet pipe and a flow slow water outlet pipe, the slow flow water inlet pipe and the flow slow water outlet pipe are communicated with the cold water tank, and a water pump is arranged on the slow flow water outlet pipe and electrically connected with the control unit through a wire. The water boiler with the liquid level stabilizing function has the advantages of effectively reducing water level fluctuation range, improving water level control accuracy, and enabling boiled water output temperature and water flow output flow to be stable.

Owner:博汭电气(苏州)有限公司

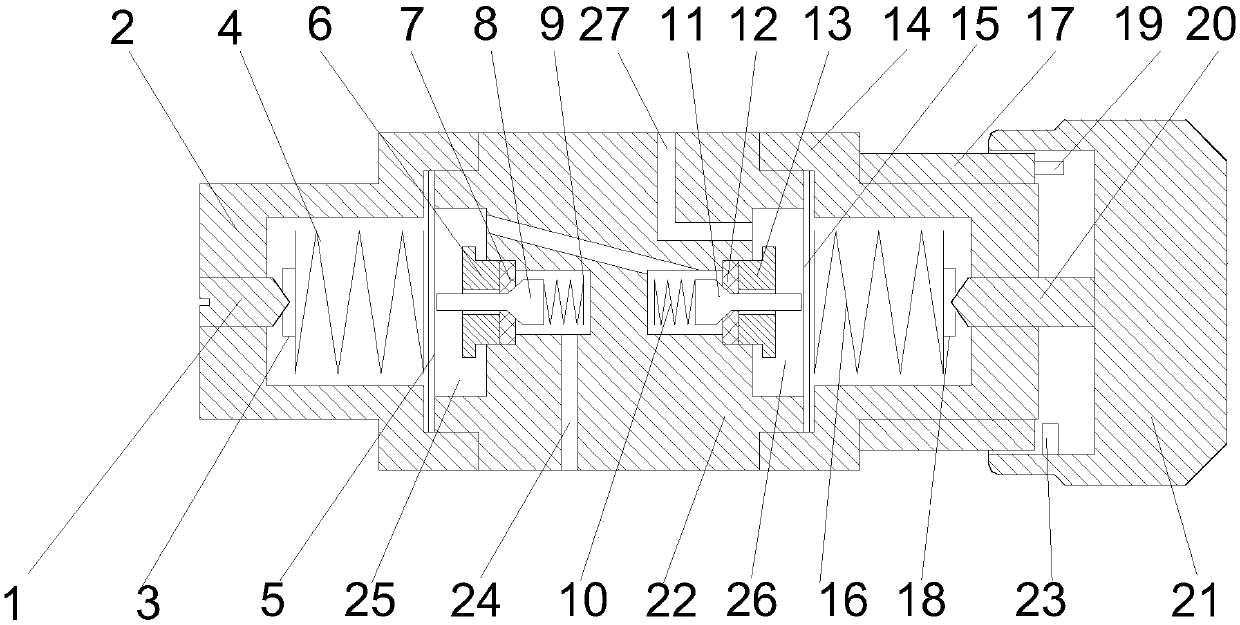

Constant pressure reducing valve

PendingCN109611593AStable output pressureStable output flowEqualizing valvesSafety valvesEngineeringMechanical engineering

The invention discloses a constant pressure reducing valve which comprises a valve body. The first end is provided with a primary low-pressure cavity and a primary transition cavity. The second end isprovided with a secondary low-pressure cavity and a secondary transition cavity. A gas inlet and a gas outlet are formed in the side wall of the valve body. The gas inlet, the primary transition cavity, the primary low-pressure cavity, the secondary transition cavity, the secondary low-pressure cavity and the gas outlet sequentially communicate. A primary pressure adjusting assembly is arranged on the communicating portion of the primary transition cavity and the primary low-pressure cavity. A secondary pressure adjusting assembly is arranged on the communicating portion of the secondary transition cavity and the secondary low-pressure cavity. A primary valve cover is connected with the first end. A primary pressure sensitive element is arranged between the primary valve cover and the first end. A primary valve cover elastic element is arranged in the primary valve cover cavity. A secondary valve cover is connected with the first end. A secondary pressure sensitive element is arrangedbetween the secondary valve cover and the first end. A secondary valve cover elastic element is arranged in the secondary valve cover cavity. A handle is fixedly connected with one end, extending outof the secondary valve cover, of a secondary ejection screw. The constant pressure reducing valve outputs pressure and flow stably and is convenient to be closed and opened.

Owner:AEROTECH BEIJING

Resin quantitative replacement device

InactiveCN101524738BRealize equivalent replacementPrevent oxidationFoundry mouldsMould handling/dressing devicesFuel tankPlunger pump

The invention provides a resin quantitative replacement device which comprises a speed regulating motor, a plunger pump and a replacement tank, wherein a rubber bag is arranged in the replacement tank, the upper end of the replacement tank is provided with a feeding pipe which extends into the rubber bag, a valve is arranged on the feeding pipe, the upper side wall of the replacement tank is provided with an oil filling hole, the side wall of the replacement tank is provided with an upper oil drain pipe and a lower oil drain pipe, valves are arranged on the oil drain pipes, the bottom of the rubber bag is provided with a resin output hole, the speed regulating motor is connected with the plunger pump by a crank, an oil filling hole of the plunger pump is connected with a hydraulic oil tank, and an oil outlet of the plunger pump is connected with the oil filling hole of the replacement tank. The invention outputs the resin by a hydraulic oil extruding method and can realize the quantitative replacement of hydraulic oil with the resin, the resin does not in direct contact with the pump, which radically avoid the damage of the pump by the resin, the pump can stably operate and does not need to be cleaned and maintained, the resin output flow is not influenced by environmental temperature to ensure the stable resin output flow, and meanwhile, the seal type resin output is adopted to prevent resin oxygenation.

Owner:冯新林

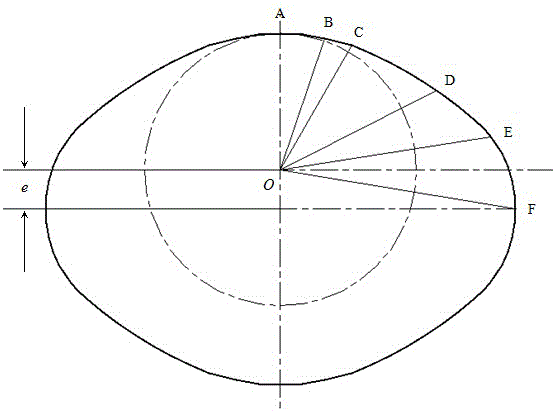

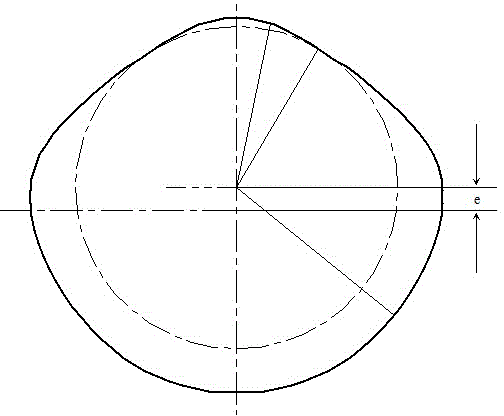

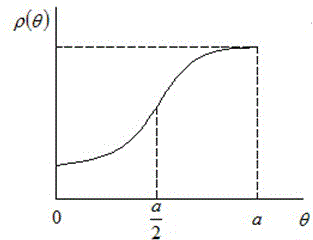

Method for designing negative camber of stator of booster vacuum pump for brake

InactiveCN104879300ASituations that reduce the rate of wearConditions that do not contribute to wear rateRotary/oscillating piston pump componentsLiquid fuel engine componentsEngineeringVacuum pump

The invention provides a method for designing the negative camber of a stator of a booster vacuum pump for brake. An integral stator curve is formed by smooth connection of a circular curve and a transitional curve, and is an arc section AB, a high-order curve section BC, an involute section CD, a high-order curve section DE and an arc section EF; a composite curve is symmetrical about XY axis; an inner curve of the whole stator is obtained according to the symmetry by only obtaining a quarter of molded line. According to the method, the high-order curve is added in the middle of the original molded line, so that the curve is smooth, the shock excitation impact phenomenon is eliminated, and the work efficiency of the booster vacuum pump is effectively prolonged.

Owner:SHANGHAI UNIV

Pipe type fuel gas pressure-relief device

The invention discloses a pipe type fuel gas pressure-relief device. The device comprises a pipe body, a fixing body, a spring, a piston and ventilating holes, wherein the two ends of the pipe body are provided with connecting threads, the space in the pipe body is composed of a high-pressure cavity and a low-pressure cavity, and the inner diameter of the high-pressure cavity is smaller than that of the low-pressure cavity; the fixing body is arranged in the low-pressure cavity and connected with the inner surface of the low-pressure cavity, and a gap for gas to pass through is formed in the fixing body; one end of the spring is connected with the fixing body; the piston is connected with the other end of the spring, and the piston is pushed by the spring to be tightly attached to the end of the high-pressure cavity; the ventilating holes are evenly formed in the pipe wall of the low-pressure cavity, the two ends of each ventilating hole are both communicated with the internal space of the low-pressure cavity, and the ventilating holes are located between the fixing body and the ends of the high-pressure cavity. The pipe type fuel gas pressure-relief device is simple in structure, small in size and capable of being conveniently connected with a fuel gas conveying pipe. Due to the pipe type fuel gas pressure-relief device, fuel gas flow turbulence can not be caused, and the situation that the flame state is not stable is avoided.

Owner:CHENGDU GUOGUANG ELECTRONICS INSTR

Electromagnetic direct-push type reversing valve

InactiveCN106439109AImprove connectivityPollution abilityServomotor componentsMultiple way valvesSolenoid valveElectromagnetic interference

The invention provides an electromagnetic direct-push type reversing valve. The electromagnetic direct-push type reversing valve comprises a valve body, a first oil channel and a valve rod, wherein the first oil channel is arranged inside the valve body; the valve rod is used for controlling the first oil channel to be connected with a second oil channel or a third oil channel; the valve rod is used for controlling the second oil channel to be connected with a fourth oil channel or controlling the third oil channel to be connected with a fifth oil channel; the two ends of the valve rod are each provided with a solenoid valve; a push rod is arranged between the second oil channel and the third oil channel; the second oil channel is connected with a first oil hole through a first one-way valve; the third oil channel is connected with a second oil hole through a second one-way valve; the push rod is capable of opening the first one-way valve in a pushing manner when approaching to the second oil channel and is capable of opening the second one-way valve in a pushing manner when approaching to the third oil channel. The reversing valve provided by the invention is high in oil liquid pollution resistance and is capable of realizing stable flow output.

Owner:HEFEI XIELI HYDRAULIC TECH CO LTD

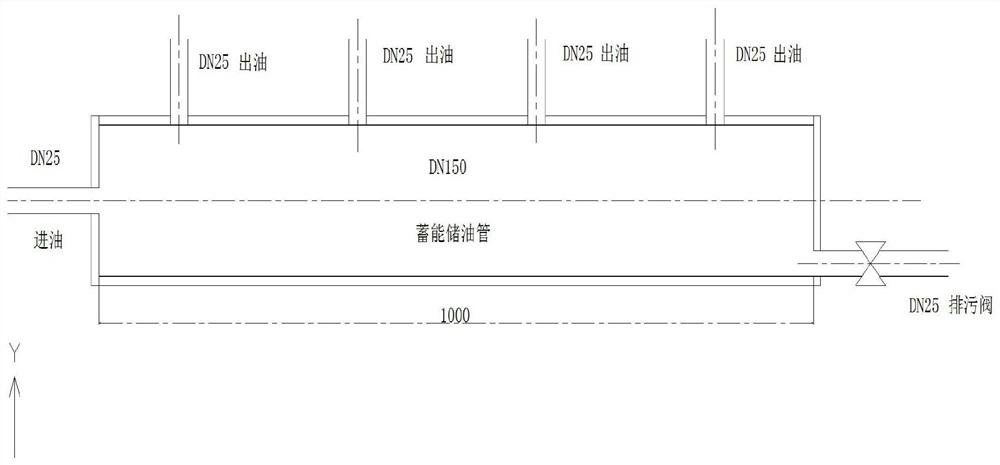

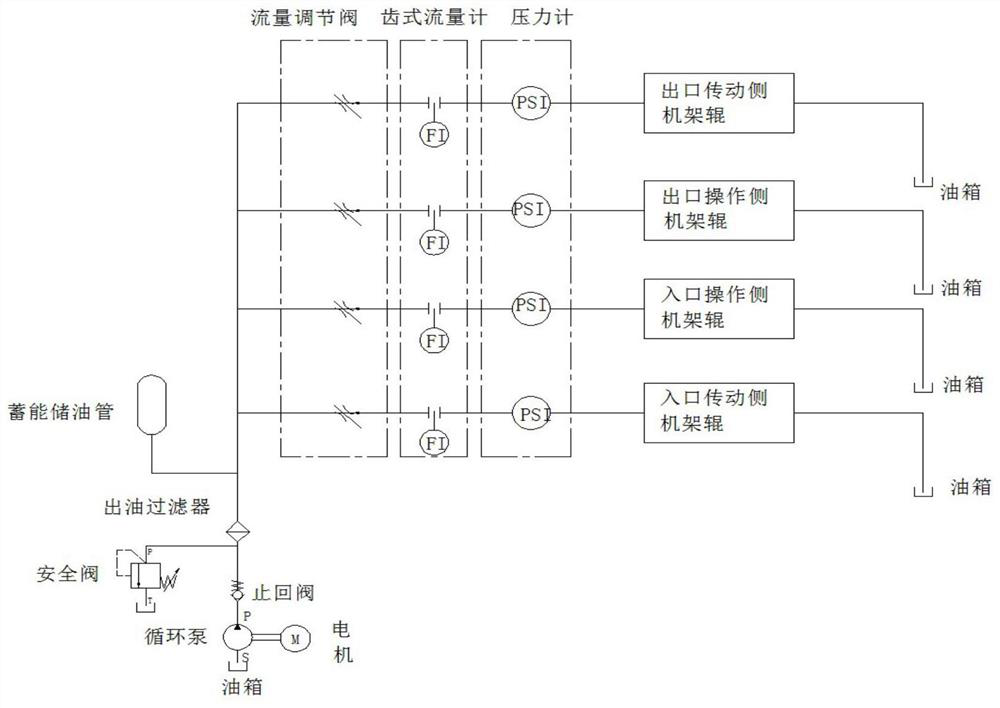

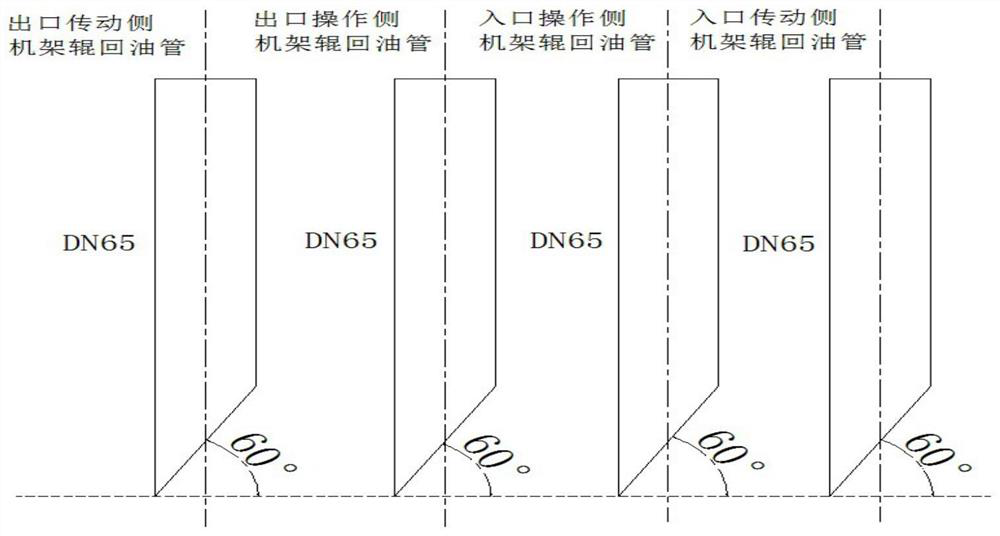

Method for improving use reliability of lubricating system for 5M rolling mill stand roll

PendingCN113653931AExtended service lifeImprove lubricationEngine pressureRolling safety devicesThermodynamicsLubrication

The invention discloses a method for improving the use reliability of a lubricating system for a 5M rolling mill stand roll. The method for improving the use reliability of the lubricating system for the 5M rolling mill stand roll is characterized in that a pipeline of the lubricating system for the rolling mill stand roll is transformed, the design that one main pipe of the original pipeline is divided into four branch pipes to lubricate four stand roll user points separately, finally, the four branch pipes are gathered to the main pipe and return to an oil tank, and only the main pipe is provided with a pressure monitor is changed into the design that the four stand roll user points are provided with an independent loop for lubrication separately, the loops do not influence one another, each loop is independently provided with a flow meter and a pressure sensor, and real-time monitoring for lubrication pressure and flow of the four stand roll user points is realized. According to the invention, poor lubrication and uneven lubrication of a stand roll bearing are effectively avoided, and the service life of the stand roll is prolonged.

Owner:NANJING IRON & STEEL CO LTD

Bolt type gas pressure reducing and regulating pipe

The invention discloses a bolt-type fuel gas pressure reducing and regulating tube. The bolt-type fuel gas pressure reducing and regulating tube comprises a tube body, a fixing body, a spring, a piston, a blind hole, a gas exhaust hole, a gas feeding strip hole and a regulating bolt, wherein the tube body comprises a low-pressure section and a high-pressure section, one end of the low-pressure section is provided with an outer ring and an inner ring, the inner surface of the outer ring is provided with an internal thread, one end of the high-pressure section is provided with an internal thread which is in thread connection with the outer ring, and the end of the high-pressure section is further provided with a circular ring groove used for containing the inner ring; the fixing body is arranged in the low-pressure section; one end of the spring is connected with the fixing body; the piston is connected with the other end of the spring; the blind hole is evenly formed in the position, located between the outer ring and the inner ring, of the end of the low-pressure section, and the starting end of the blind hole is provided with an internal thread; the gas exhaust hole is formed in the low-pressure section and enables the low-pressure section to be communicated with the tail end of the blind hole; the gas feeding strip hole is formed in the inner surface of the end of the low-pressure section; the regulating bolt is in thread connection with the blind hole. The bolt-type fuel gas pressure reducing and regulating tube can be used for conveniently regulating pressure of output fuel gas.

Owner:广州中桥能源科技有限公司

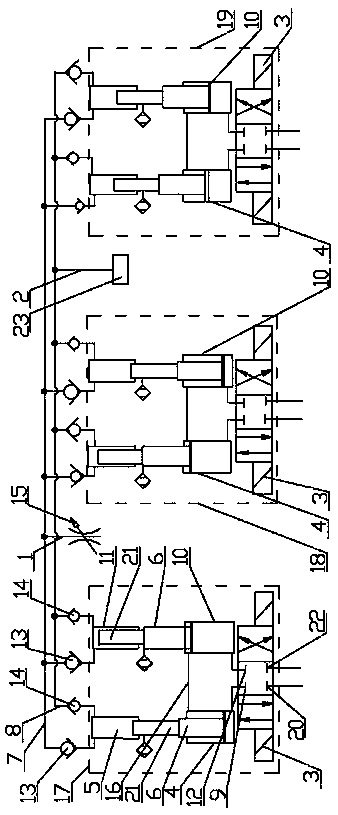

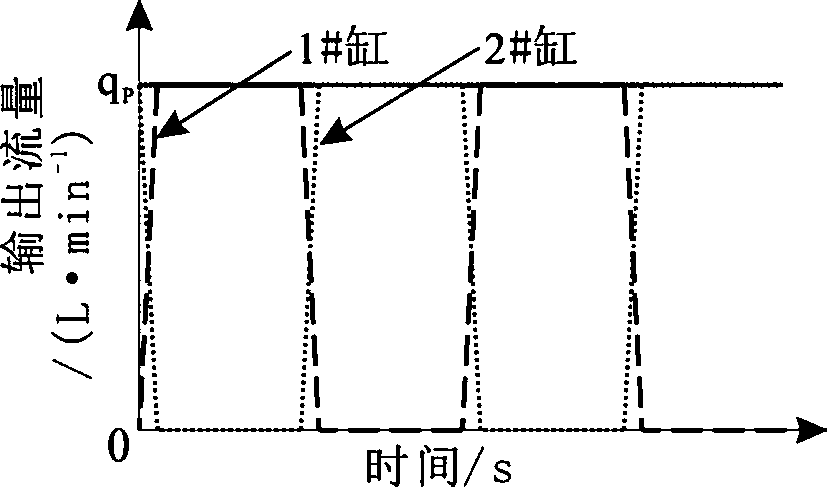

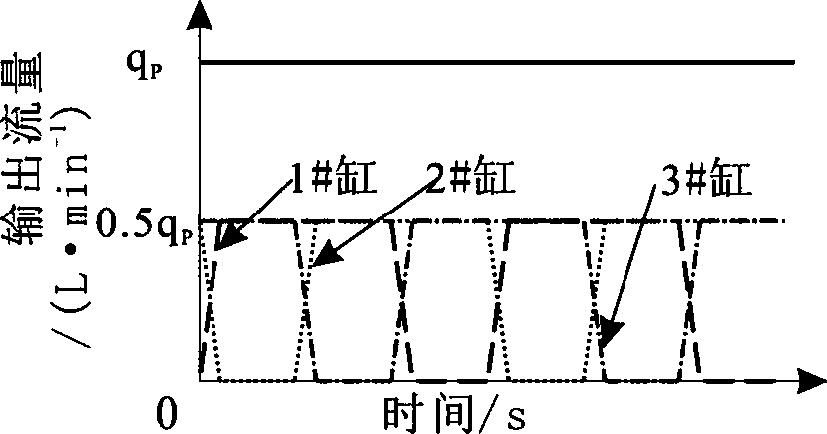

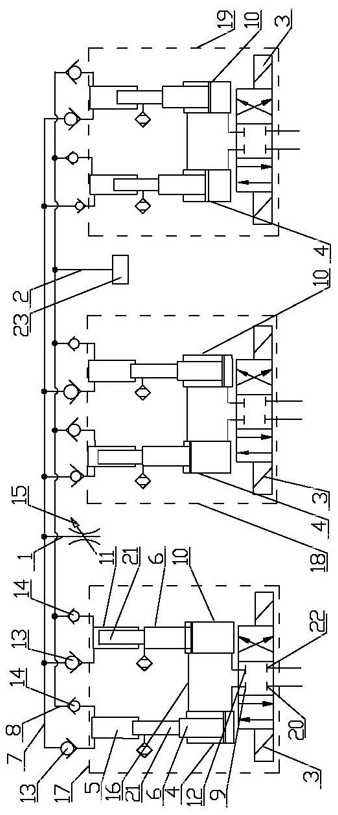

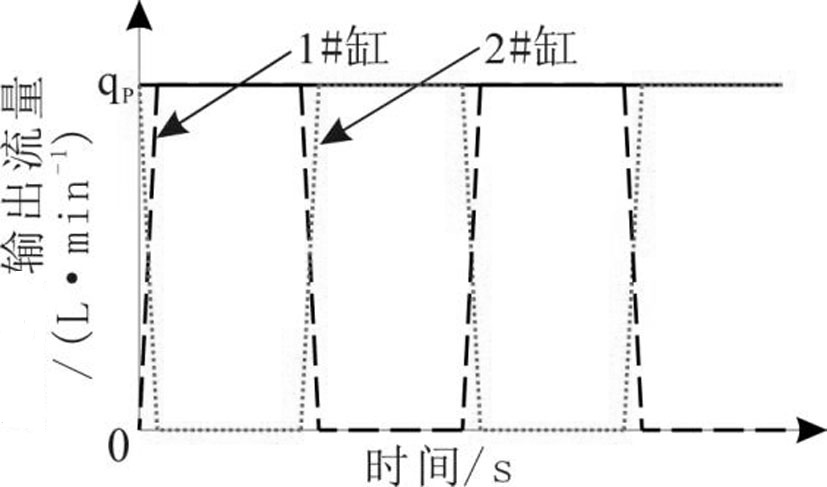

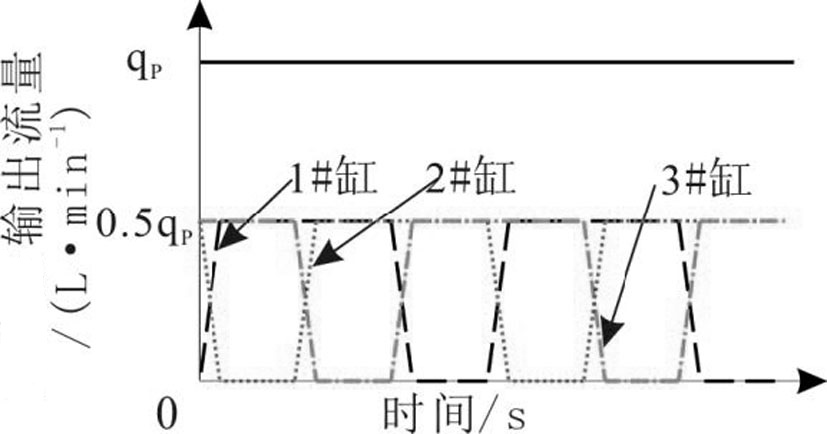

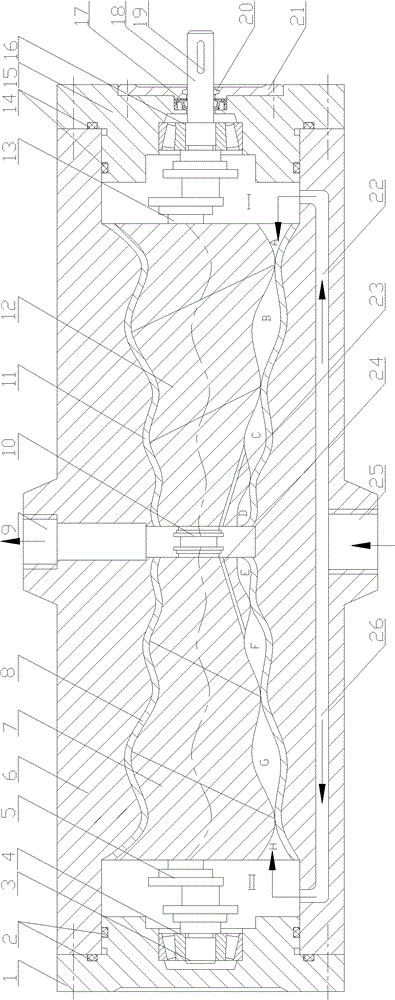

Position-based multi-hydraulic-cylinder coordination control method and device for stably outputting liquid

ActiveCN111173793AStable output flowSmall flow and pressure pulsationsServomotor componentsServomotorsEngineeringCoordinate control

The invention relates to the technical field of multiple sets hydraulic cylinder control, in particular to a position-based multi-hydraulic-cylinder coordination control method and device for stably outputting liquid. Before n sets of hydraulic cylinders work, the positions of pistons of the n sets of hydraulic cylinders are initialized firstly, then the hydraulic cylinders start to work, by detecting the positions of the pistons or piston rods or plungers of one set of hydraulic cylinders, the other set of hydraulic cylinders is controlled to reverse, ordered reversing of the multiple sets ofhydraulic cylinders is achieved, the starting and accelerating process of the mth set of hydraulic cylinders and the decelerating and stopping process of the (m + 1) th set of hydraulic cylinders arecompletely overlapped, and perfect overlapping of the output flow is achieved. According to the method, by detecting the positions of the piston rods or the plungers of one set of hydraulic cylindersand controlling reversing of reversing valves of the other set of hydraulic cylinders, ordered reversing of the multiple sets of hydraulic cylinders is achieved, the output flow is stable, and flow and pressure pulsation are small.

Owner:XINJIANG UNIVERSITY

A steady flow valve for a pump

ActiveCN106949110BAdjustable cracking pressureProcess stabilityServomotor componentsEngineeringMechanical engineering

The invention discloses a current stabilization valve for a pump. The current stabilization valve comprises a valve body, an oil inlet and an oil return port formed in the valve body; a current stabilization spring cavity and an output oil way connected with the oil inlet are also arranged in the valve body; a current stabilization valve element is slidingly arranged in the current stabilization spring cavity, and is provided with a piston section; the piston section is arranged between the oil return port and the oil inlet; a current stabilization valve base is connected to the valve body behind the current stabilization valve element; a return spring is arranged between the current stabilization valve element and the current stabilization valve base; a throttling port is formed in the output oil way; the output oil way behind the throttling port is connected with the current stabilizing spring cavity behind the current stabilization valve element through a connecting hole; a blind hole is formed in the back section of the current stabilization valve element; a pressure limiting valve is arranged in the blind hole; and the front section of the blind hole is connected with the oil return port through a radial hole. When the oil supply quantity of an oil pump and the load of a hydraulic system are changed, the current stabilization valve can basically keep the output flow stable to meet the requirements of stable rotating speed and steering stability of a host machine so as to guarantee normal work of the host machine.

Owner:四川长江液压件有限责任公司

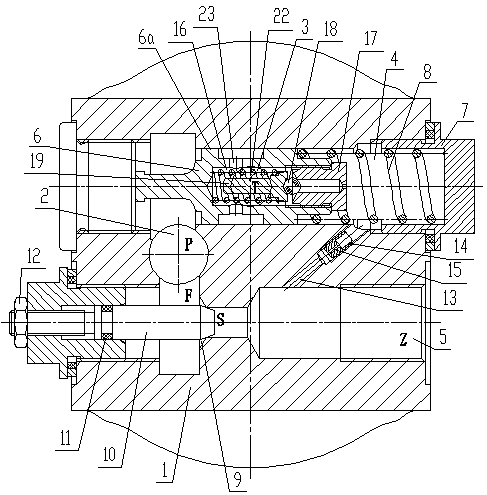

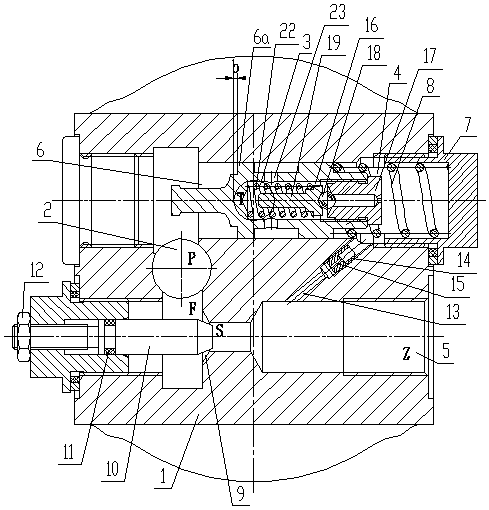

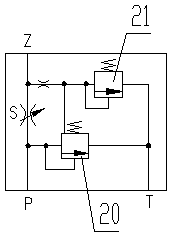

Electric-hydraulic proportional plunger pump

InactiveCN107701385AChange displacementHigh control precisionPositive displacement pump componentsPositive-displacement liquid enginesOil distributionControl valves

The invention discloses an electric-hydraulic proportional plunger pump, which belongs to the technical field of plunger pumps, and comprises a plunger pump body and a control device for adjusting pump displacement. The plunger pump body comprises a bearing and a central rod used for connecting the bearing and the control device and provided with an axial line forming an included angle with an axial line of the bearing; a plurality of plungers connected with the bearing are arranged around the central rod; the control device comprises an electromagnet, a displacement and feedback force systemand a control valve element for connecting the electromagnet and the displacement and feedback force system; and an oil distribution disc for installing the central rod is arranged on the displacementand feedback force system. The invention provides the plunger pump which has the displacement capable of being adjusted from zero to maximum infinitude, and is convenient to adjust, higher in rotaryspeed and stain resistant.

Owner:广州华欣液压科技股份有限公司

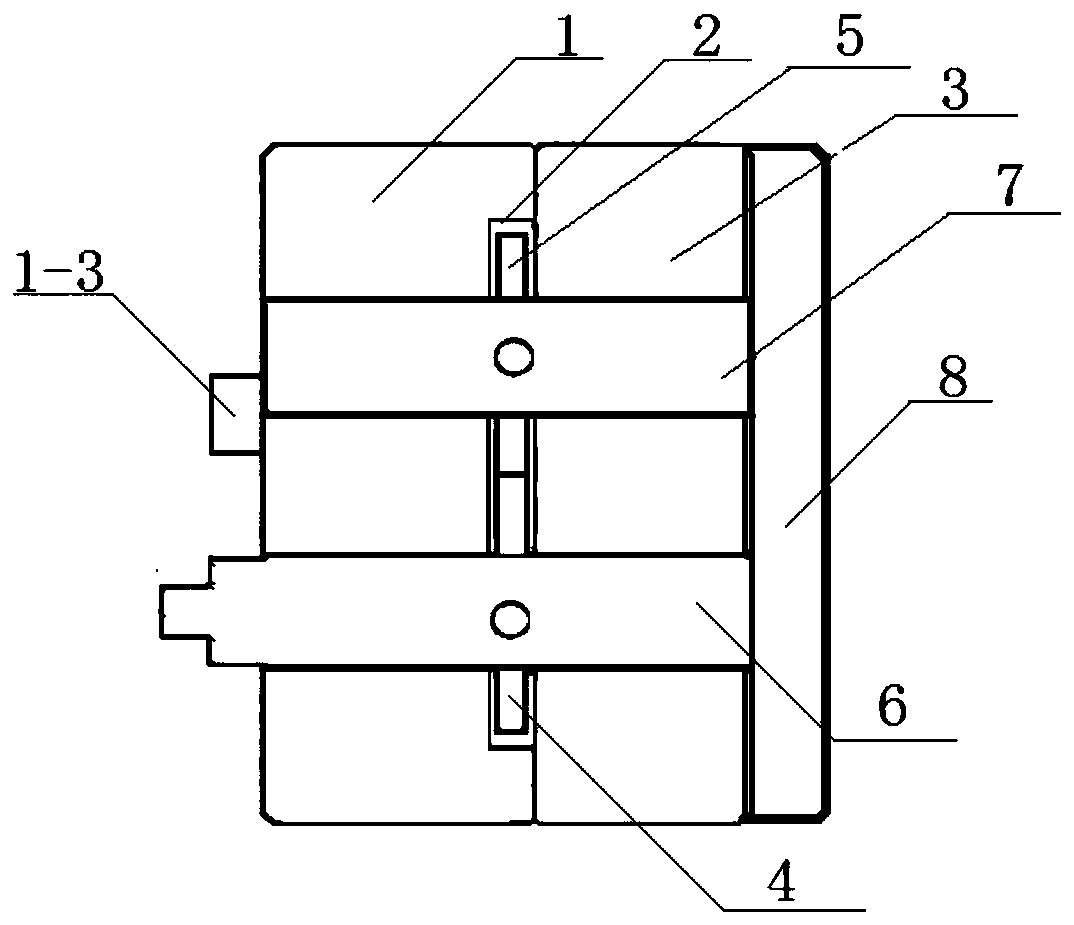

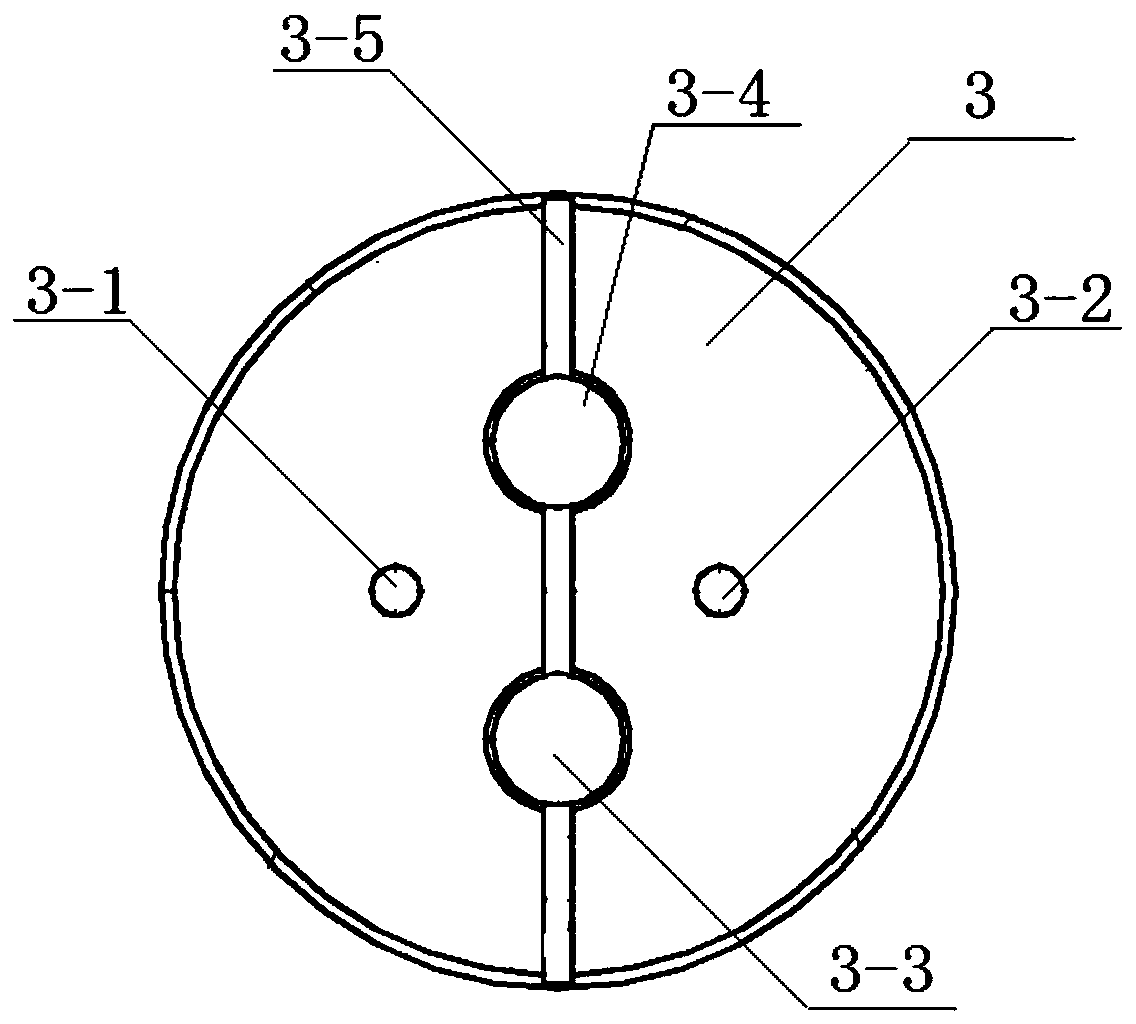

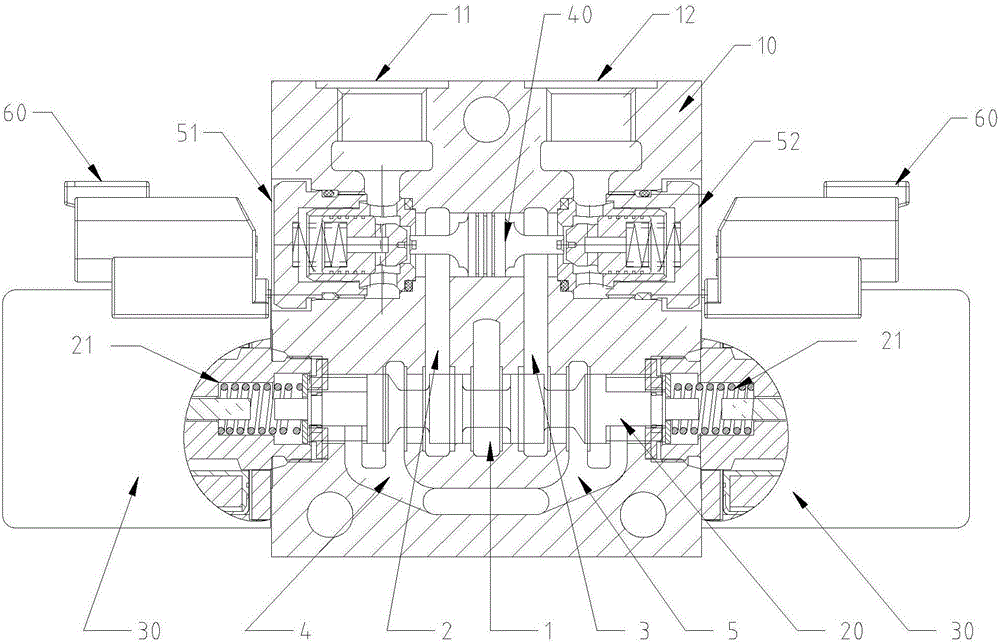

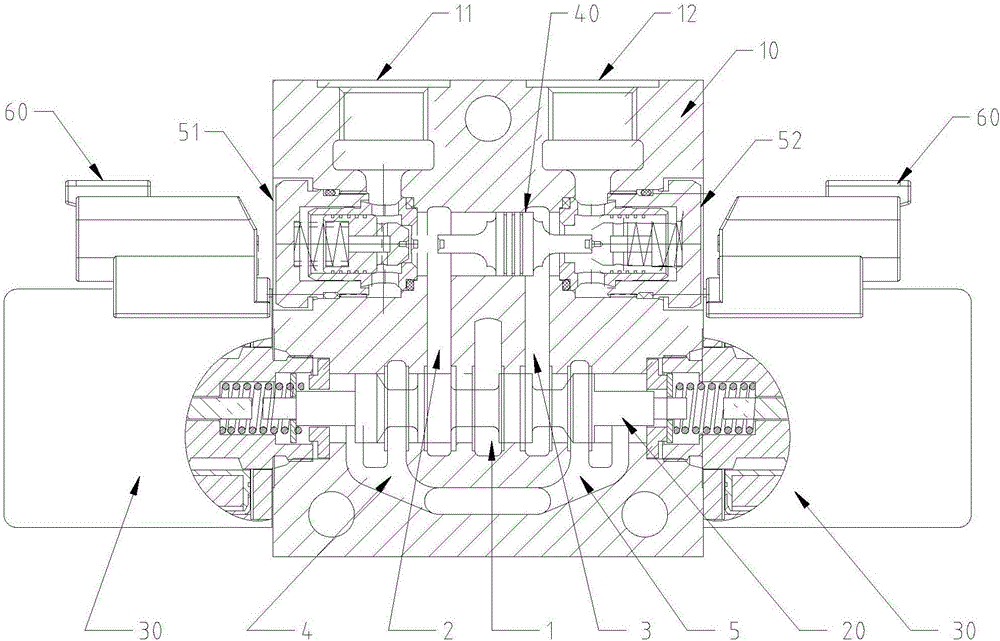

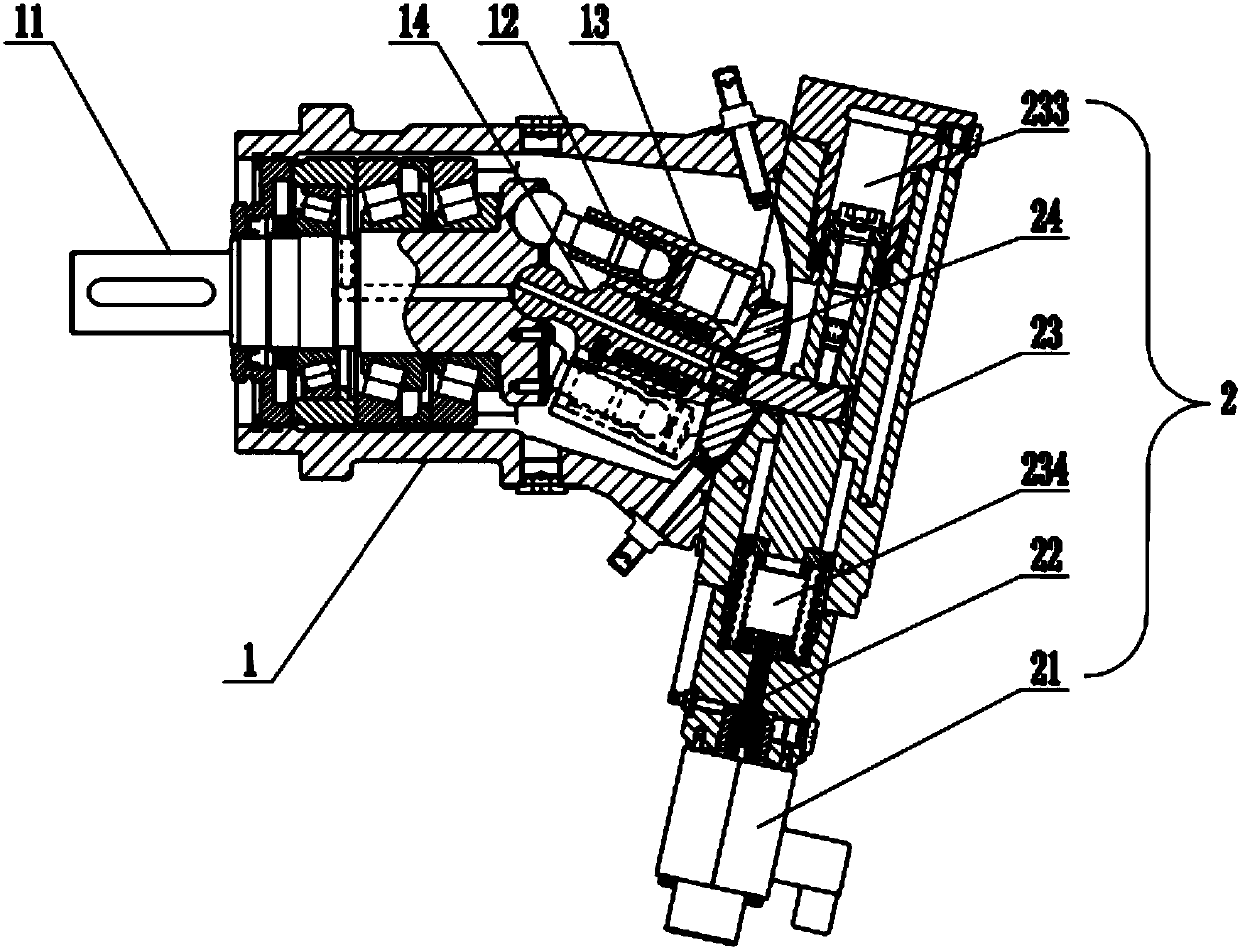

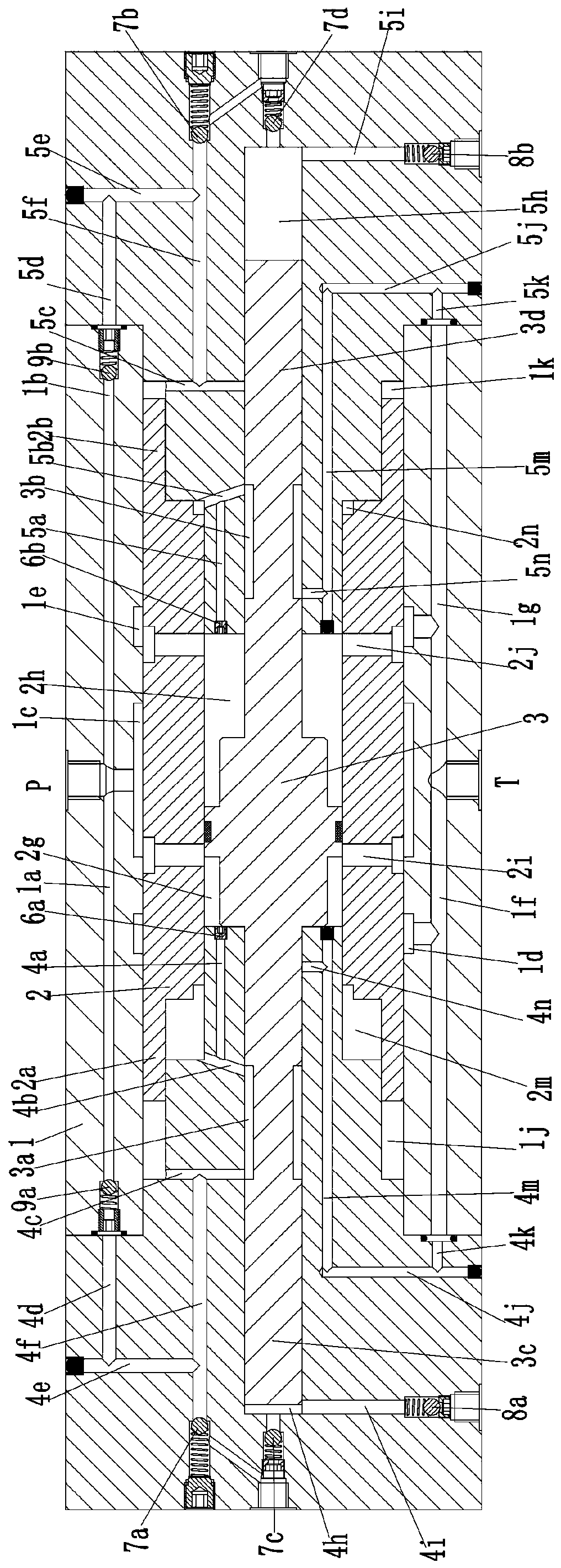

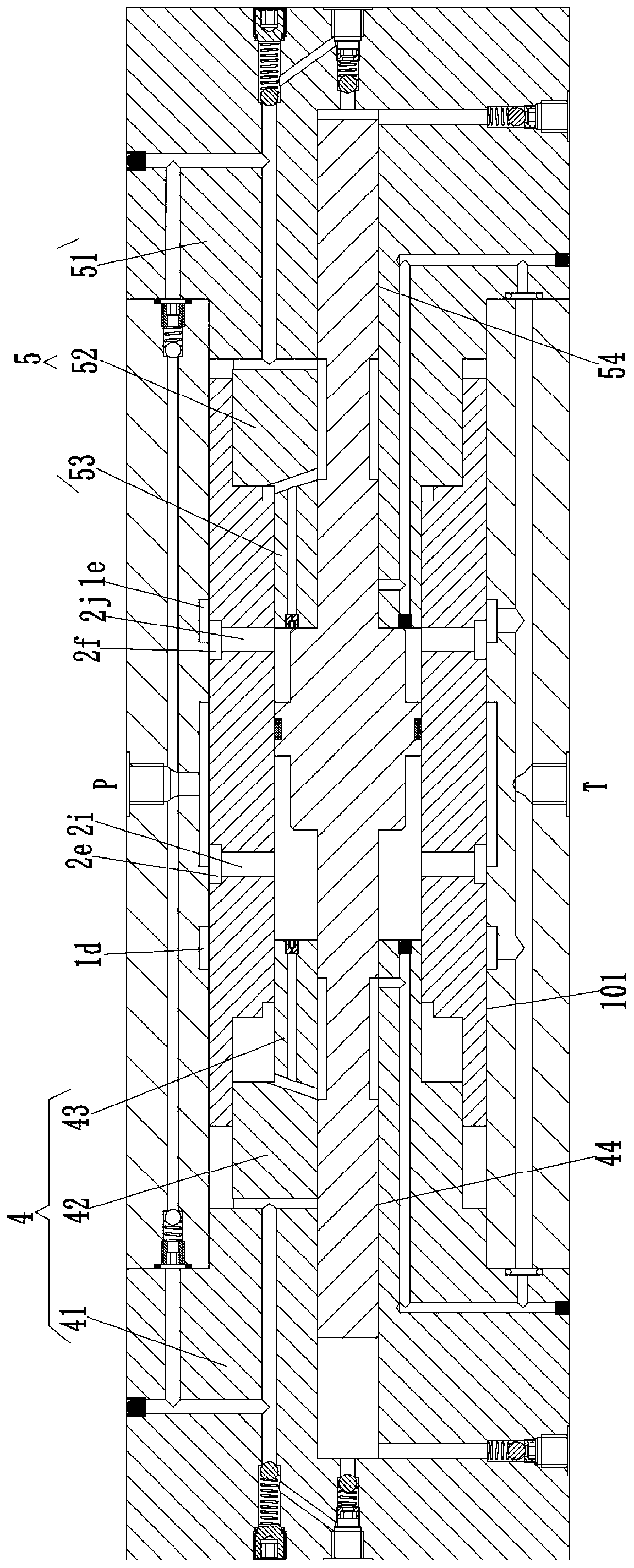

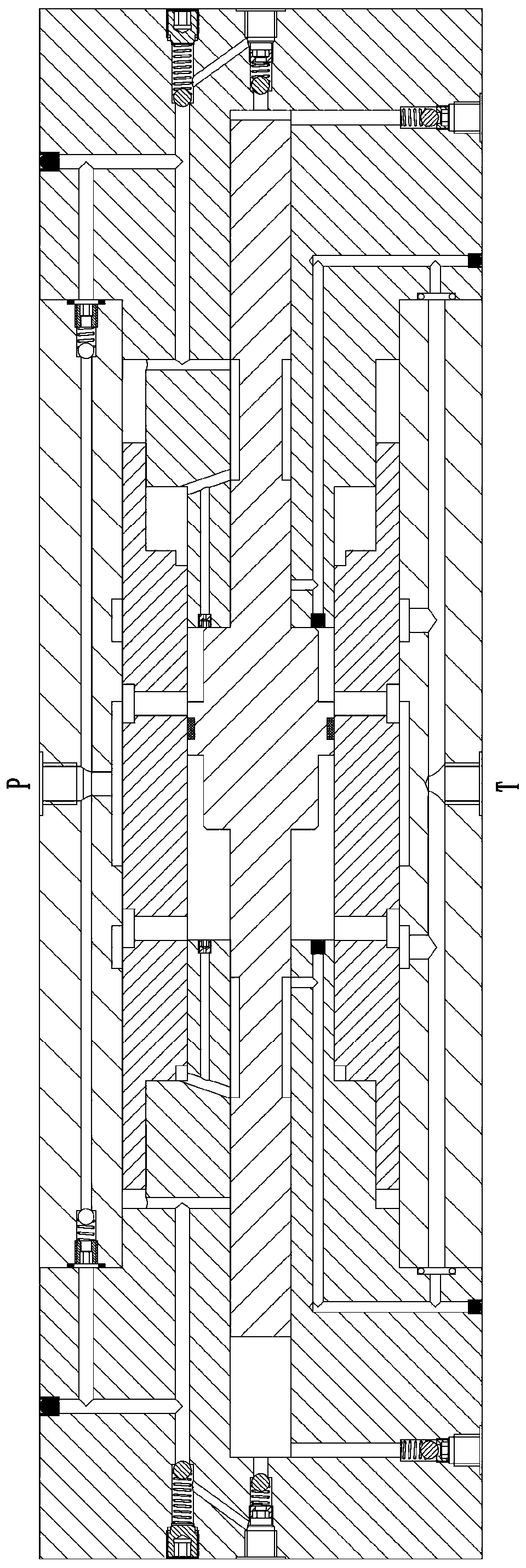

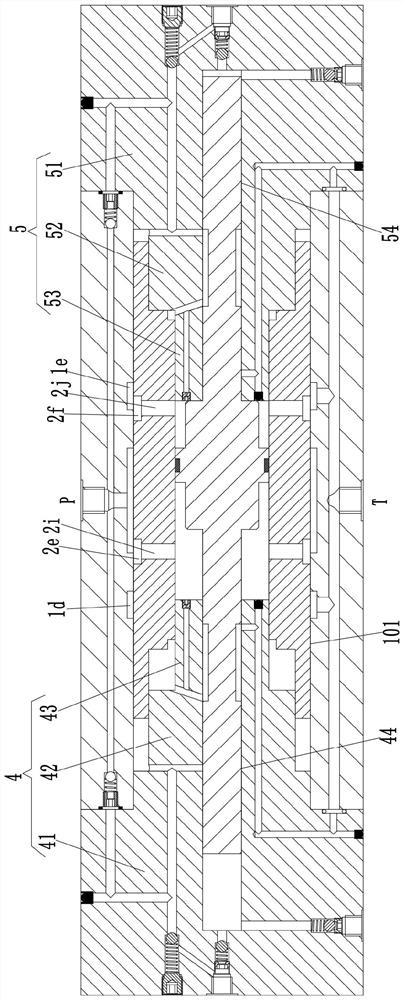

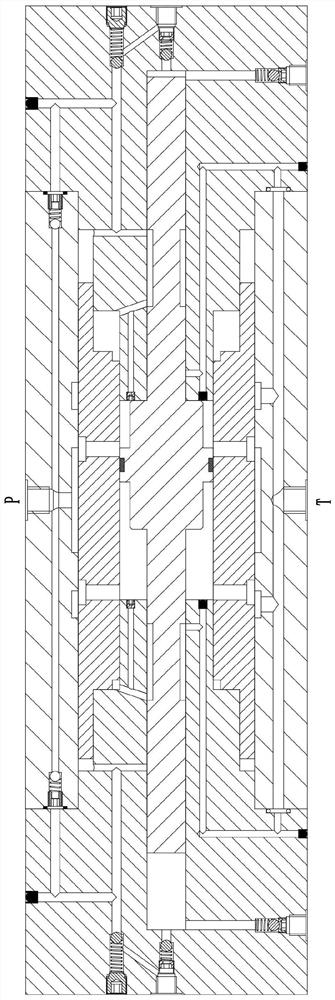

Double-plunger supercharger

ActiveCN111120427ALarge displacementHighly integrated designFluid-pressure convertersStructural engineeringElectric control

The invention discloses a double-plunger supercharger. The double-plunger supercharger comprises a machine body, wherein a mounting hole is formed in the machine body; a port P and a port T which communicate with the mounting hole are formed in the side surface of the machine body; a left end cover is mounted on the left side of the machine body, and a right end cover is mounted on the right sideof the machine body; the left end cover comprises a left body; a left first convex column is arranged on the left body; a left second convex column is arranged at the right end of the left first convex column; the right end cover comprises a right body; a right first convex column is arranged on the right body; a right second convex column is arranged at the left end of the right first convex column; a cylinder sleeve is slidably connected in the mounting hole; a power piston is slidably connected in the cylinder sleeve; a left piston cavity is formed between the left end of the power piston and the left second convex column in the cylinder sleeve, and a right piston cavity is formed between the right end of the power piston and the right second convex column in the cylinder sleeve; a leftpump assembly is arranged in the left end cover; and a right pump assembly is arranged in the right end cover. The double-plunger supercharger is highly integrated in integral design, space and partsare saved, moreover, oil ways are reduced, control is simple, and in addition, electric control is not required.

Owner:宁波真格液压科技有限公司

Position-based multi-hydraulic cylinder coordinated control method and device for smooth output of liquid

ActiveCN111173793BInherently low commutation time requirementsStable outputServomotor componentsServomotorsHydraulic cylinderMechanical engineering

The invention relates to the technical field of multi-group hydraulic cylinder control, and relates to a position-based multi-hydraulic cylinder coordinated control method and device for stably outputting liquid. , and then the hydraulic cylinder starts to work. By detecting the position of a group of hydraulic cylinder pistons or piston rods or plungers, it controls the reversal of another group of hydraulic cylinders to achieve orderly reversal of multiple groups of hydraulic cylinders, and the startup of the mth group of hydraulic cylinders is accelerated. The process completely overlaps with the deceleration and stop process of the m+1 group of hydraulic cylinders, and the output flow is perfectly superimposed. The invention controls the reversing valve direction of another group of hydraulic cylinders by detecting the position of the piston rod or plunger of one group of hydraulic cylinders to realize orderly reversal of multiple groups of hydraulic cylinders, stable output flow, and small flow and pressure pulsation.

Owner:XINJIANG UNIVERSITY

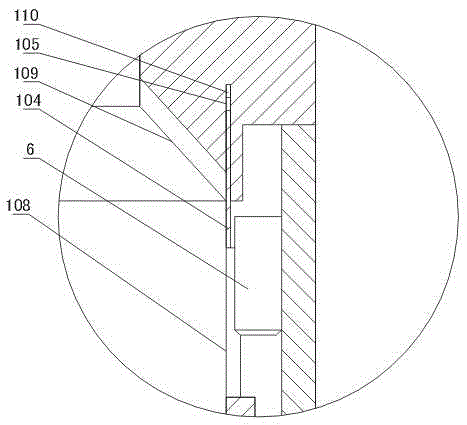

A double plunger supercharger

ActiveCN111120427BLarge displacementHighly integrated designFluid-pressure convertersStructural engineeringMechanical engineering

The invention discloses a double-plunger supercharger, which comprises a machine body, a mounting hole is arranged in the body, a P port and a T port communicated with the mounting hole are arranged on the side of the body; the left side of the body is installed There is a left end cover, and a right end cover is installed on the right side; the left end cover includes a left body, the left body is provided with a left post, and the right end of the left post is provided with a left two post; the right end cover includes a right body, a right The body is provided with a right convex column, and the left end of the right convex column is provided with a right two convex column; a cylinder liner is slidably connected in the installation hole; a power piston is slidably connected in the cylinder liner; A left piston chamber is formed between the left end of the power piston and the two left convex posts, and a right piston chamber is formed between the right end of the power piston and the two right convex posts; Pump assembly; the double plunger supercharger is not only highly integrated in overall design, saving space and parts, but also reduces oil passages, simple control, and no need for electric control.

Owner:宁波真格液压科技有限公司

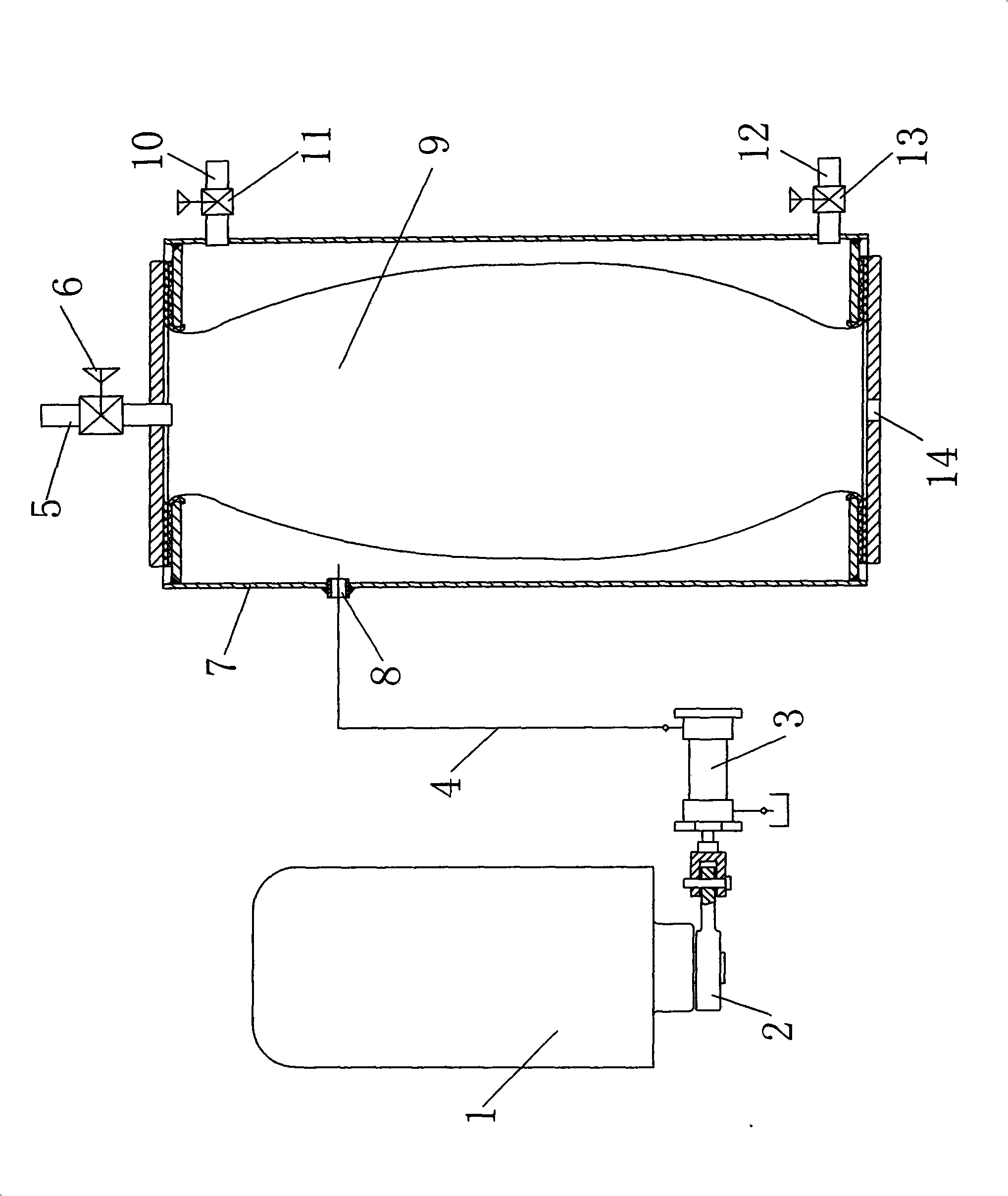

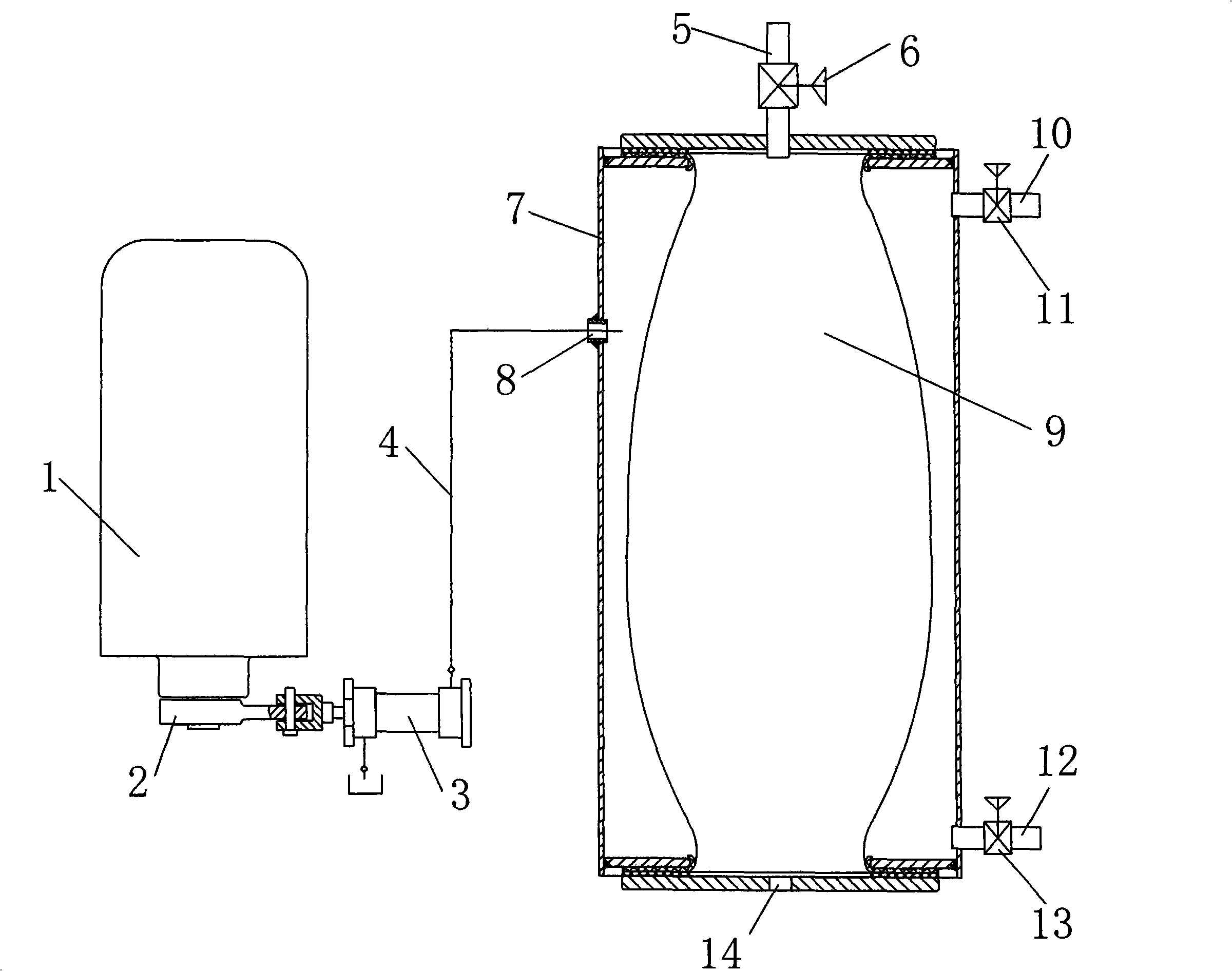

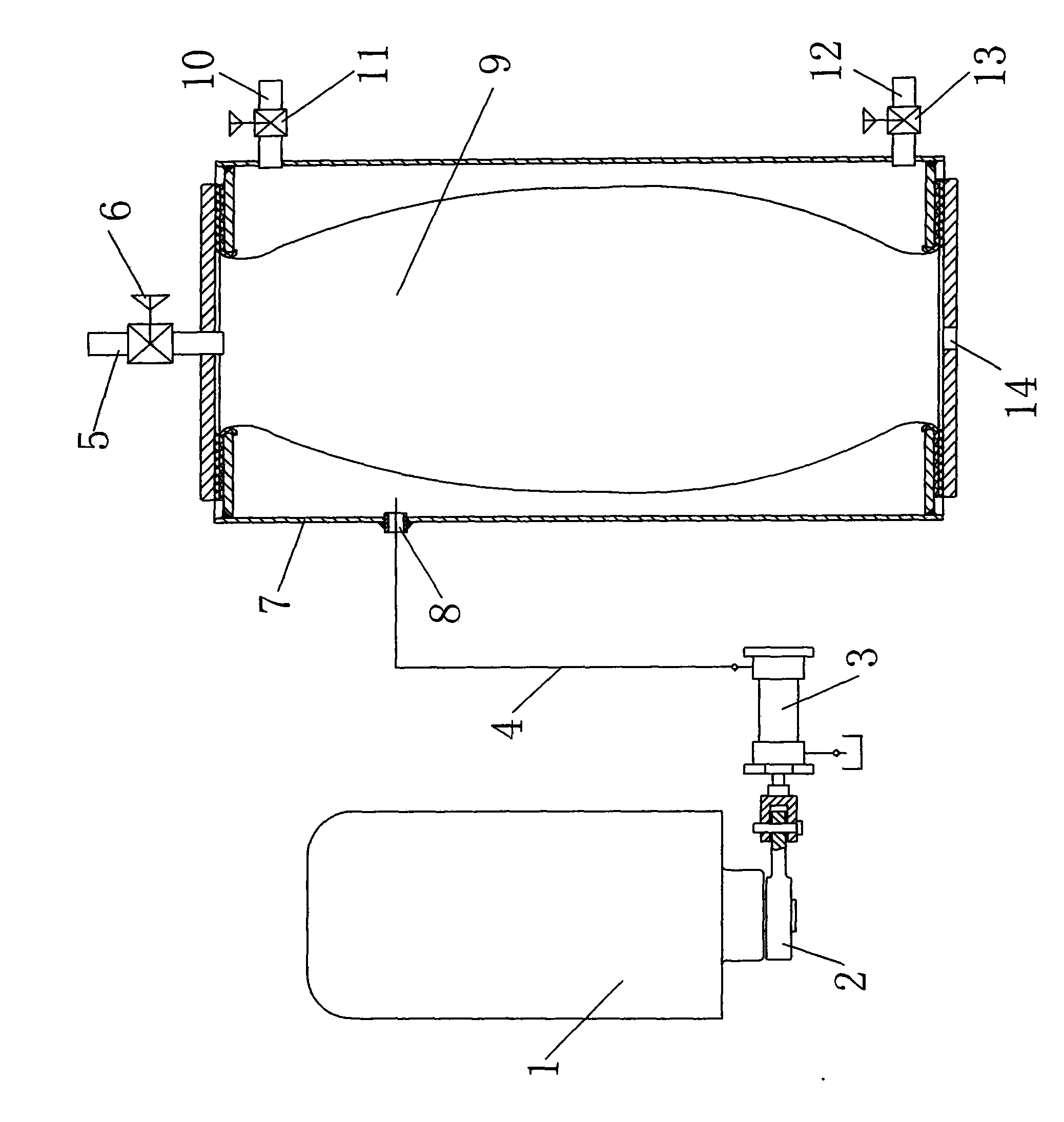

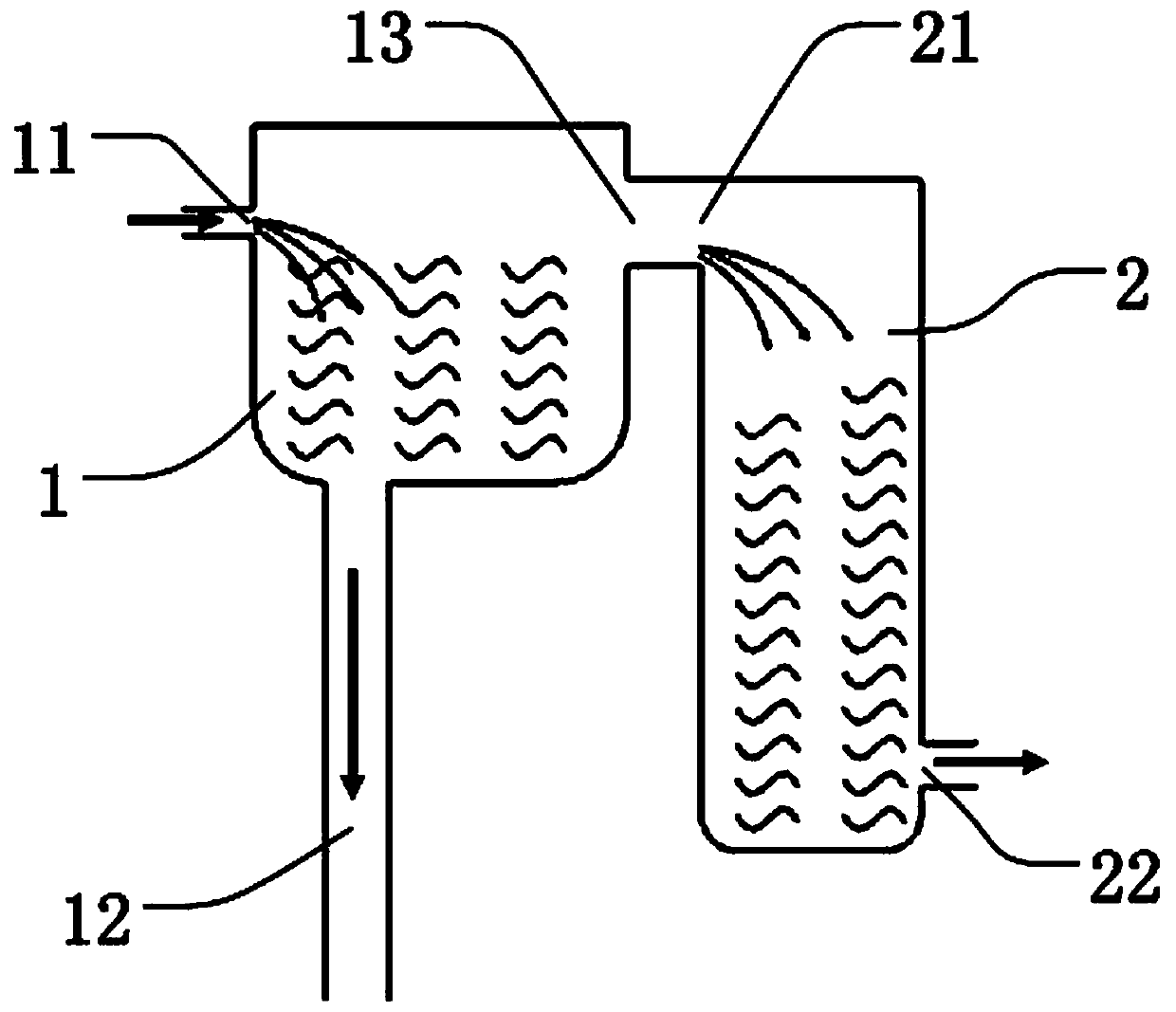

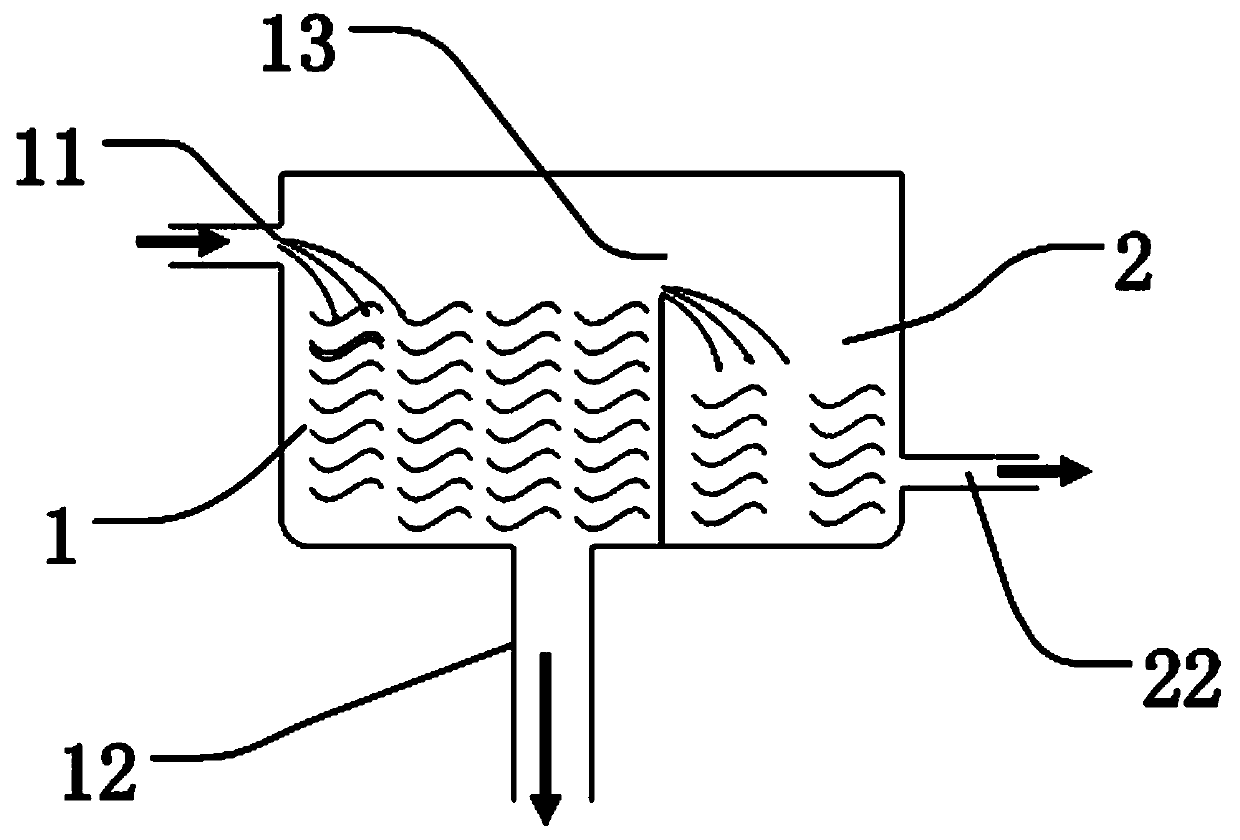

A liquid storage tank with stable liquid output flow

ActiveCN103057871BStable output flowHigh control precisionLarge containersLiquid storage tankEngineering

The invention discloses a liquid storage tank capable of stabilizing liquid output flow. The liquid storage tank includes a main tank for storing liquid and further includes a limit device for limiting a height of a liquid level in the main tank, wherein the main tank is provided with a main tank liquid inlet for importing liquid and a main tank liquid outlet for draining liquid. The liquid storage tank capable of stabilizing liquid output flow has the advantages of stabilizing liquid levels of containers by limiting heights of the liquid levels in the containers so that the liquid output flow is stabilized, and being high in control accuracy.

Owner:上海莹致节能电器有限公司

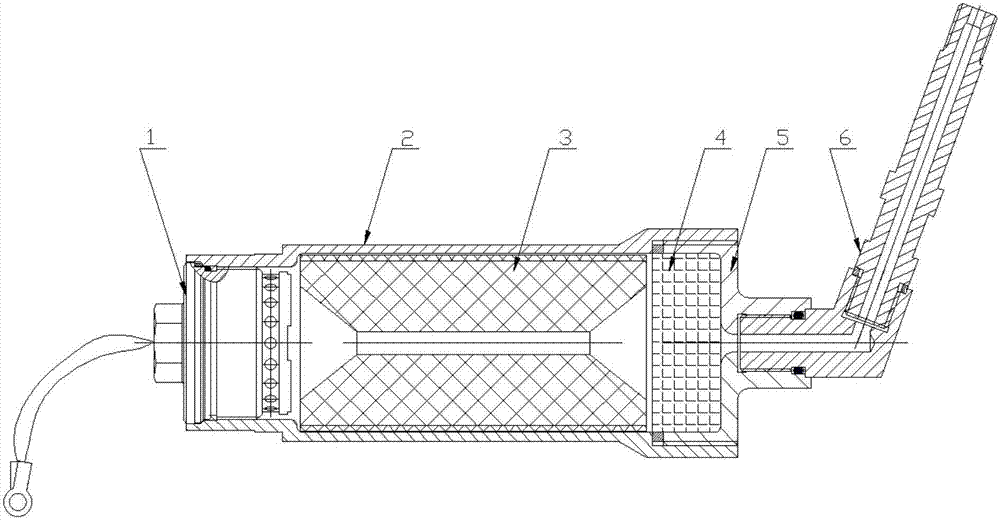

A solid gas starter

ActiveCN106481457BSimple structureEasy to assembleGas turbine plantsJet propulsion plantsCombustion chamberCopper

The invention discloses a solid gas starter applied to a turbojet engine. The solid gas starter comprises an igniting tool, a combustion chamber, a propellant, a filter screen, an end socket and a gas pipeline. The igniting tool adopts a double-bridge igniting circuit, is in threaded connection with the combustion chamber and adopts a copper gasket and O-shaped ring double-layer sealing structure; the combustion chamber and the end socket are in threaded connection with each other and are sealed by adopting a copper gasket; the propellant adopts a double-base propellant and an unsaturated polyester coating layer; the propellant form is of a combustion structure with two ends which are each provided with an inner taper hole; the combustion chamber is freely filled with the propellant; the filter screen is formed in a columnar shape by adopting a molybdenum wire by means of one-time mold pressing and is embedded inside the end socket; the end socket and the gas pipeline are in threaded connection with each other and are sealed by adopting an O-shaped ring; and an outlet end of the gas pipeline is provided with an external interface thread by means of machining. The solid gas starter disclosed by the invention can solve the problems that the gas of a start source for a conventional turbojet engine is high in temperature and unstable in gas flow and contains lots of gas residues. The solid gas starter disclosed by the invention can output low-temperature clean gas and is stable in output flow.

Owner:XIAN MODERN CHEM RES INST

Novel energy-saving dosing pump

InactiveCN104564629AHigh precisionRealize closed-loop controlPump controlPositive-displacement liquid enginesControl systemMedicine

The invention discloses a novel energy-saving dosing pump which structurally comprises a pump body, an adjuster and an automatic flow control system. The novel energy-saving dosing pump has the advantages that the flow rate of the dosing pump can be monitored in real time, and the adjuster of the dosing pump can be adjusted automatically according to flow change, so that the output flow rate of the dosing pump can be more accurate.

Owner:NINGXIA QIKAI ENERGY SAVING EQUIP

Machine tool lifting stability control method and system and tractor

PendingCN114876889AAchieve floating controlStable output flowServomotor componentsServomotorsAutomatic controlSolenoid valve

The invention discloses a machine tool lifting stability control method and system and a tractor, and belongs to the technical field of tractors. An inlet of the main pump is connected with an oil tank, an outlet of the main pump is sequentially connected with an electromagnetic switch valve, a compensation valve, a rising control electromagnetic valve and a first electromagnetic reversing valve, an outlet of the first electromagnetic reversing valve is connected with a rod cavity and a rodless cavity of the suspension oil cylinder, and the first one-way valve is connected between the first electromagnetic reversing valve and the rodless cavity of the suspension oil cylinder. An inlet of the descending control solenoid valve is connected between a rodless cavity of the suspension oil cylinder and the first one-way valve, an outlet of the descending control solenoid valve is connected with an oil tank, and the first solenoid directional valve and the compensation valve are further provided with outlets connected with the oil tank. Stable control over ascending and descending of the machine tool is achieved, an electromagnetic directional valve is additionally arranged, a strong pressure mode of a hard land parcel and machine tool floating control are achieved, a compensation valve is arranged in a matched mode, output flow and pressure stability are achieved, and the combined automatic control over hydraulic output and machine tool ascending and descending and the field edge management function are achieved.

Owner:XCMG AGRI EQUIP TECH CO LTD

High-pressure seawater hydraulic pump for double-cone opposite-cone threaded rod

InactiveCN102619747BEliminate trapped oilFlow rate changes evenlyRotary piston pumpsRotary piston liquid enginesCouplingHydraulic pump

The invention provides a high-pressure seawater hydraulic pump for a double-cone opposite-cone threaded rod, belonging to a volume type hydraulic pump. A core part of the high-pressure seawater hydraulic pump is a pair of cone-shaped threaded rods and a layer of bushing block with equal thickness. The two cone-shaped threaded rods with the same structure and size and the different rotating directions are symmetrically arranged at two sides of a universal coupling, and small ends of the two cone-shaped threaded rods are respectively connected with two ends of the universal coupling, so that a double-cone opposite structure is formed, and the thickness of each position on the same cross section of the bushing block is equal to one another; and a liquid passageway is formed on the cone-shaped threaded rod which is nearest to a discharge end and forms into an integrated seal chamber, and the passageway is communicated with a seal chamber and a discharge-end chamber. After the double-cone opposite structure is adopted, the whole structure of a screw pump is balanced in force application, so that the defects such as eccentric wear, leakage and the like caused by the unbalanced force application can be removed; and static pressure support is formed between the threaded rods and the bushing block, so that the threaded rod has the function of the static pressure support, therefore, the wear between the threaded rods and the bushing block can be reduced, the moving stability of the hydraulic pump can be improved, and the hydraulic pump is small in noise, long in service life, high in output pressure, stable in output flow, and small in pressure pulsation.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com