Machine tool lifting stability control method and system and tractor

A technology of smooth control and implements, applied in the field of tractors, can solve problems such as poor lifting and lowering stability of tractors, achieve the effects of good micro-motion control, improve response time, and reduce hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

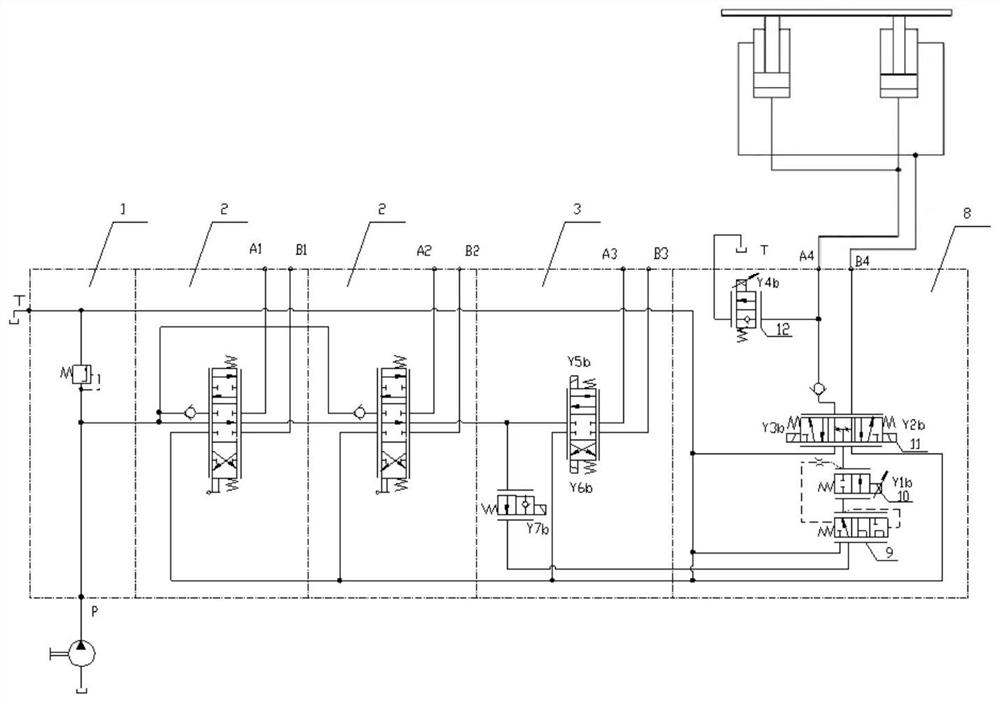

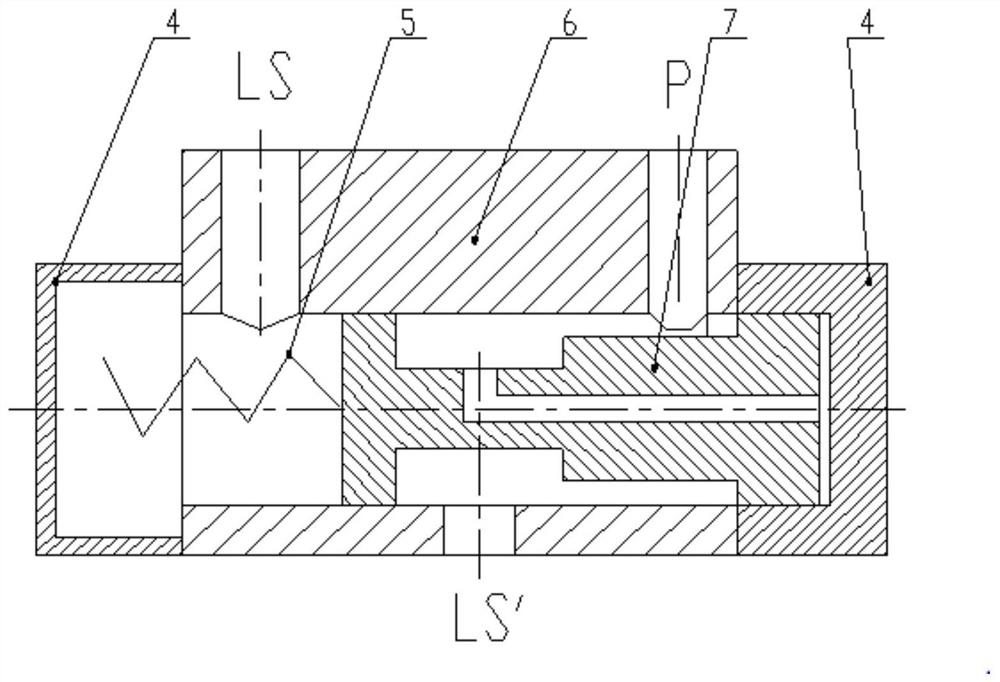

[0042] This embodiment provides a smooth control system for the lifting and lowering of the implement, the hydraulic principle diagram of which is as follows figure 1 As shown, it includes oil inlet 1, mechanical hydraulic output 2, electronically controlled hydraulic output 3, lift control 8, and the suspension cylinder in the suspension mechanism, including the oil tank, the main pump, the electromagnetic switch valve, the compensation valve 9, The ascending control solenoid valve 10, the first electromagnetic reversing valve 11, the first one-way valve, the descending control solenoid valve 12 and the suspension oil cylinder in the suspension mechanism; the inlet of the main pump is connected to the oil tank, and the outlet is sequentially connected with the electromagnetic switch valve and the compensation valve 9. The ascending control solenoid valve 10 and the first electromagnetic reversing valve 11, the outlet of the first electromagnetic reversing valve 11 is connected...

Embodiment 2

[0049] This embodiment provides a smooth control method for the lifting and lowering of an implement, based on the figure 1 The hydraulic schematic diagram shown is used for control, and the control methods of the above-mentioned smooth control system for lifting and lowering of the machine are provided under the four states (the machine is raised, the machine is lowered by its own weight, the machine is forced to fall, and the machine is floating). The control method can be continuous control or any combination, specifically:

[0050] When the mechanical hydraulic output coupling 2 and the electronically controlled hydraulic working coupling 3 do not work, when the lifting control coupling 8 works,

[0051] method one:

[0052] The Y7b of the electromagnetic switch valve is not energized. When the Y1b of the ascending control solenoid valve 10 is energized, the compensation valve 9 works in the left function position, and the Y3b of the first electromagnetic reversing valve ...

Embodiment 3

[0074] Based on the smooth control system for machine lifting according to Embodiment 1 and the method for smoothly controlling machine lifting according to Embodiment 2, this embodiment provides a tractor equipped with the machine lifting and lowering according to Embodiment 1. A smooth control system is provided, and based on the smooth control method of the implement lifting and lowering described in Embodiment 2, the implement is controlled to ascend and descend smoothly, and the automatic control of the hydraulic output of the tractor is realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com