A print head structure and its printer

A print head and printer technology, applied to typewriters, printing, transfer materials, etc., can solve the problems of inaccurate cutting position, inaccurate front and rear position, inaccurate printing position, etc., to achieve easy installation and mass production, simplify Structure and assembly method, effect of preventing wrinkling and cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

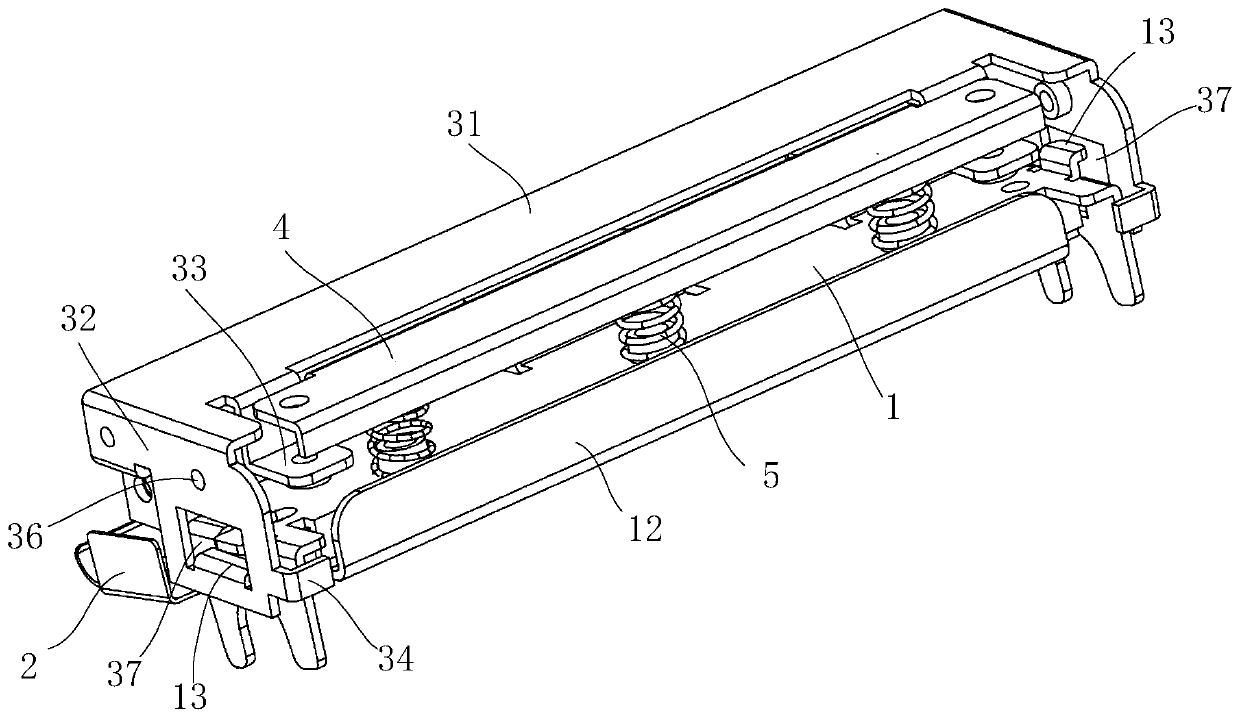

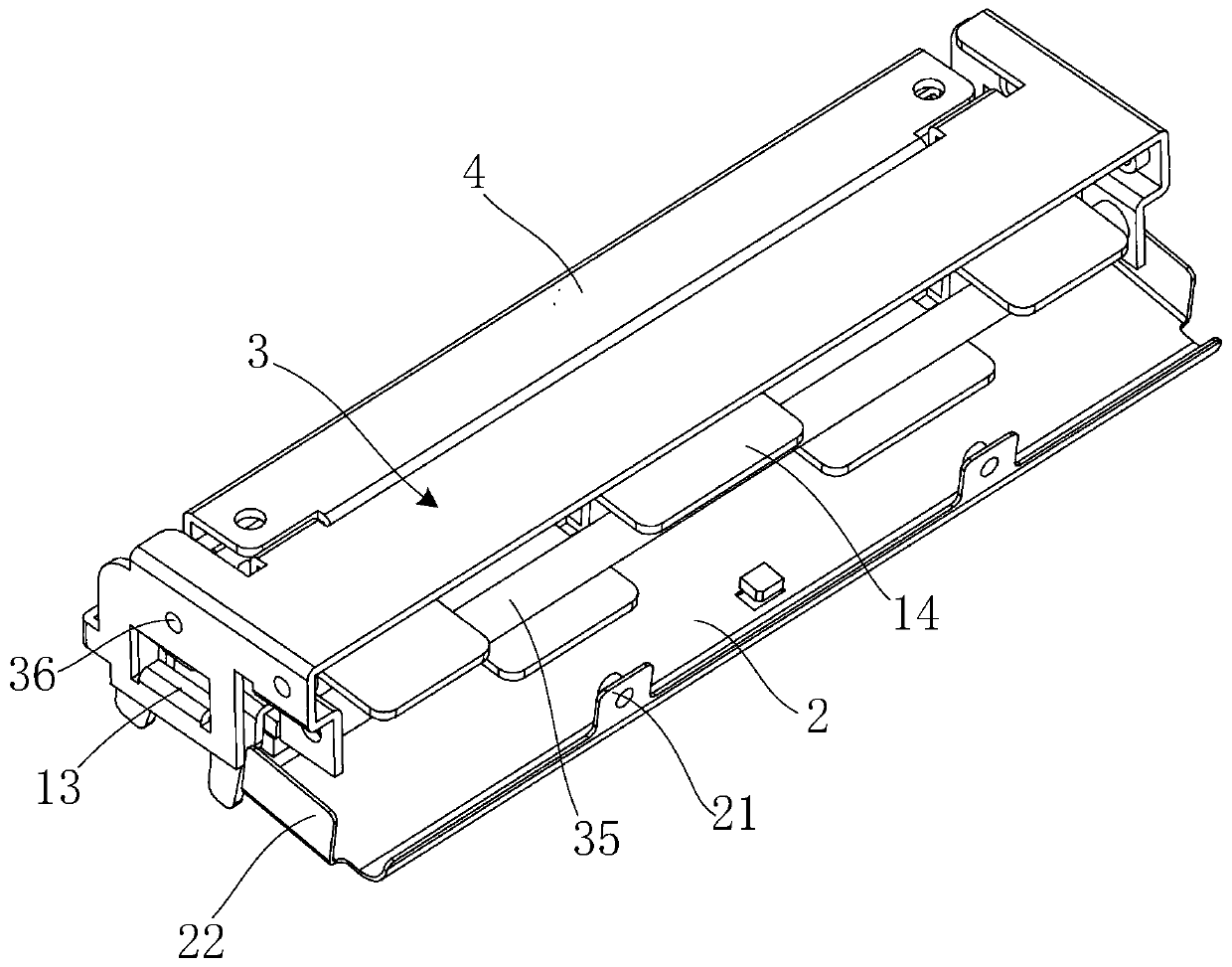

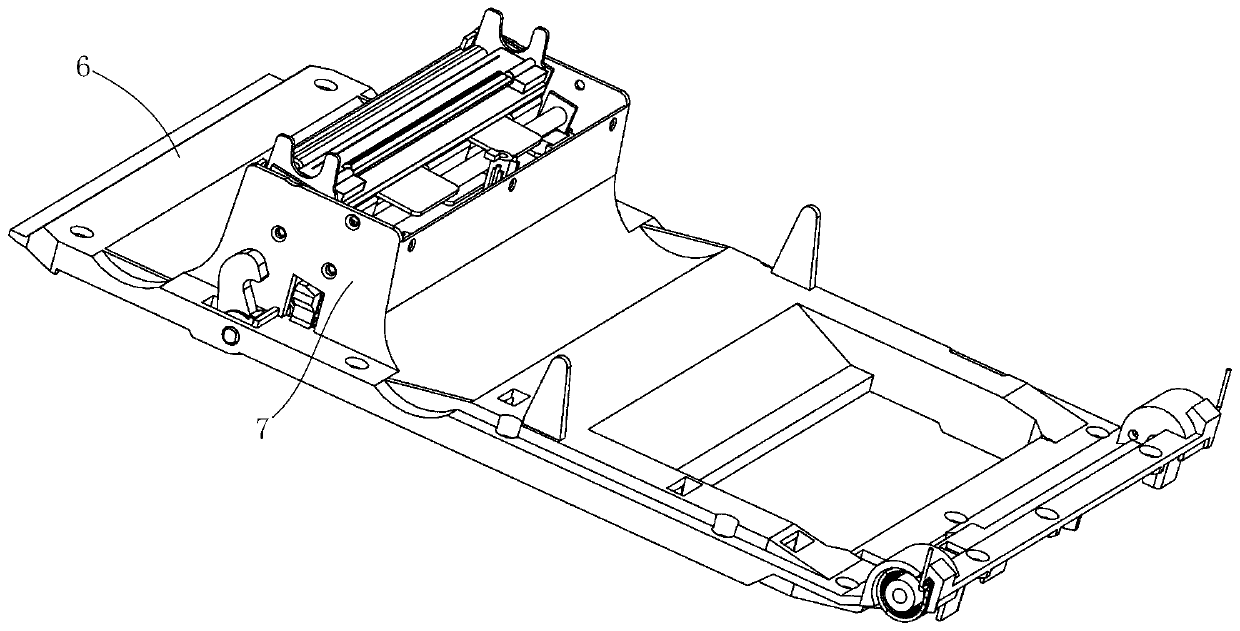

[0049] Such as figure 1 , figure 2 and Figure 5 As shown, a print head structure includes a print head support 1, a print head 11 is installed in the middle and lower part of the print head support 1, and a guide structure 12 is integrally formed on the front of the print head support 1. The cross section of the guide structure 12 is U-shaped. The key is , also includes a carbon ribbon guide frame 2, the carbon ribbon guide frame 2 is located at the rear side of the print head support 1, specifically at the rear side of the print head 11, for guiding the carbon ribbon, the carbon ribbon guide frame 2 and the print head support 1 independent of each other to form a split structure and thus float independently of each other. The ribbon guide frame 2 can be installed on the upper case of the printer, and the print head support 1 can be directly or indirectly installed on the upper case of the printer, and a floating pressing structure is arranged between the upper case and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com