Position-based multi-hydraulic cylinder coordinated control method and device for smooth output of liquid

A coordinated control, multi-hydraulic cylinder technology, used in fluid pressure actuation devices, fluid pressure actuation system components, servo motors, etc., can solve the problems of output flow and pressure pulsation, and achieve small flow and pressure pulsation, output flow The effect of stable and stable output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

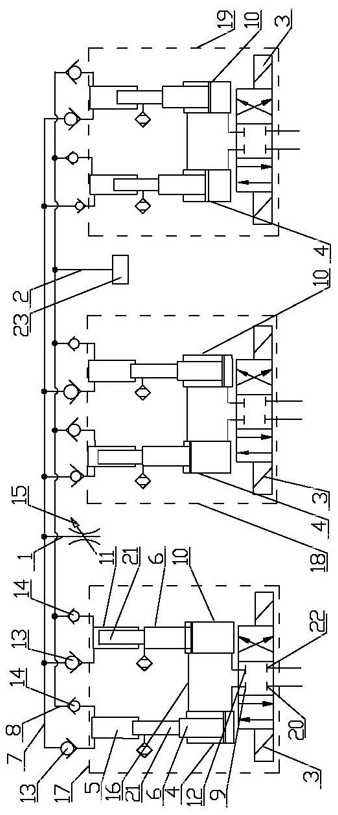

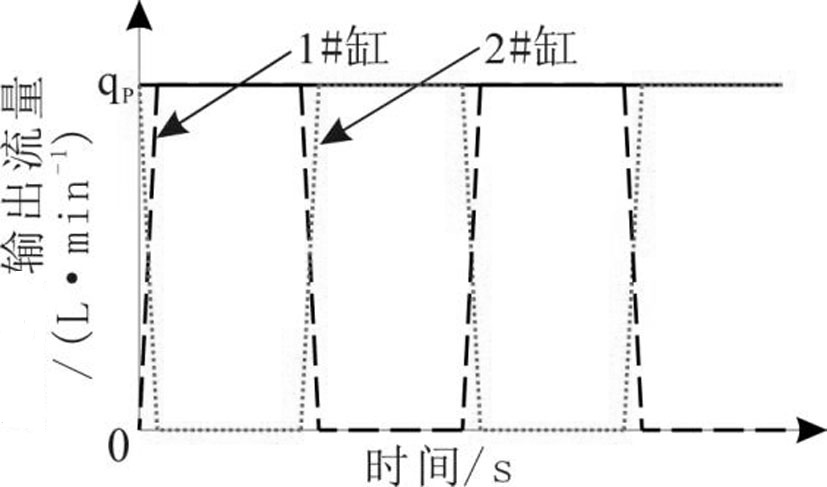

[0028] Embodiment 1: The position-based multi-hydraulic cylinder coordinated control method for smoothly outputting liquid is carried out as follows: before the n groups of hydraulic cylinders work, the strokes of the n groups of hydraulic cylinders are initialized, and the n groups of hydraulic cylinders are respectively in At the starting point of the stroke, near the end point, and at the (n-m+1) / (n-1) stroke, any group of hydraulic cylinders in the n groups of hydraulic cylinders is recorded as the mth group of hydraulic cylinders, 1≤m≤n, m, n are all natural numbers;

[0029] After the hydraulic cylinder stroke of each group of hydraulic cylinders is initialized, the hydraulic cylinder starts to work, the mth group of hydraulic cylinders is in a stop waiting state (at the starting point of the stroke), and the other groups of hydraulic cylinders move normally. When the m+1th group of hydraulic cylinders is about to reach the stroke At the end point, control the reversing ...

Embodiment 2

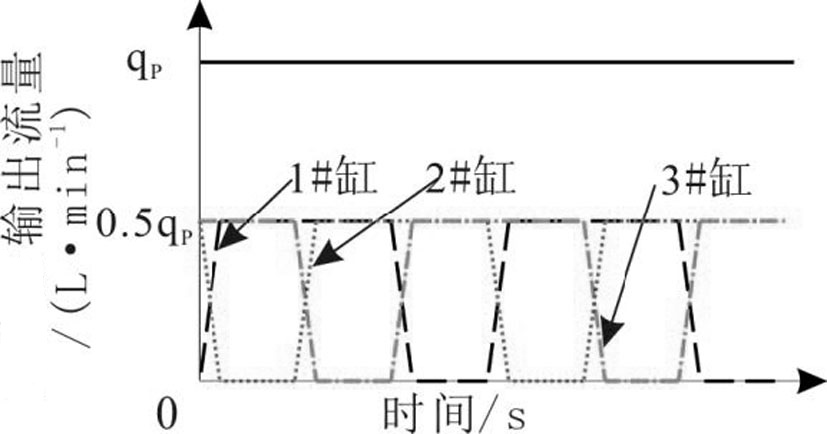

[0030] Embodiment 2: As an optimization of the above embodiment, the position-based multi-hydraulic cylinder coordinated control method for smoothly outputting liquid is carried out as follows: when n is three, before the three groups of hydraulic cylinders work, firstly control the three groups of hydraulic cylinders. The piston position of the hydraulic cylinder is initialized. The initial states of the three groups of hydraulic cylinders are at the starting point, middle point and end point of the stroke respectively, that is, the piston of any one of the hydraulic cylinders in group I 17 is at the starting point of the stroke, and the hydraulic cylinder in group II 18. The piston of any one of the piston cylinders is at the end of the stroke, and the piston of any one of the cylinders in the third group of hydraulic cylinders 19 is at the midpoint of the stroke, and then the three groups of hydraulic cylinders start to work,

[0031] Group II hydraulic cylinder 18 and group...

Embodiment 3

[0032] Embodiment 3: As an optimization of the above-mentioned embodiment, the difference from Embodiment 2 is that the position-based multi-hydraulic cylinder coordinated control method for smoothly outputting liquid is carried out as follows: when n is four, at four Before the group of hydraulic cylinders work, initialize the piston positions of the four groups of hydraulic cylinders. The initial states of the four groups of hydraulic cylinders are at the starting point, end point, 2 / 3 stroke, and 1 / 3 stroke, respectively, that is, group I. The piston of any piston cylinder in hydraulic cylinder 17 is at the starting point of the stroke, the piston of any piston cylinder in group II hydraulic cylinder 18 is at the end of the stroke, and the piston of any piston cylinder in group III hydraulic cylinder 19 is at 2 / 3 stroke. , the piston of any one of the cylinders in the IV group is at 1 / 3 of the stroke, and then the four groups of hydraulic cylinders start to work,

[0033] W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com