High-pressure seawater hydraulic pump for double-cone opposite-cone threaded rod

A cone-screw and hydraulic pump technology, which is applied in the direction of pumps, rotary piston pumps, liquid fuel engines, etc., to achieve the effects of uniform flow changes, reduced wear, and high output pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

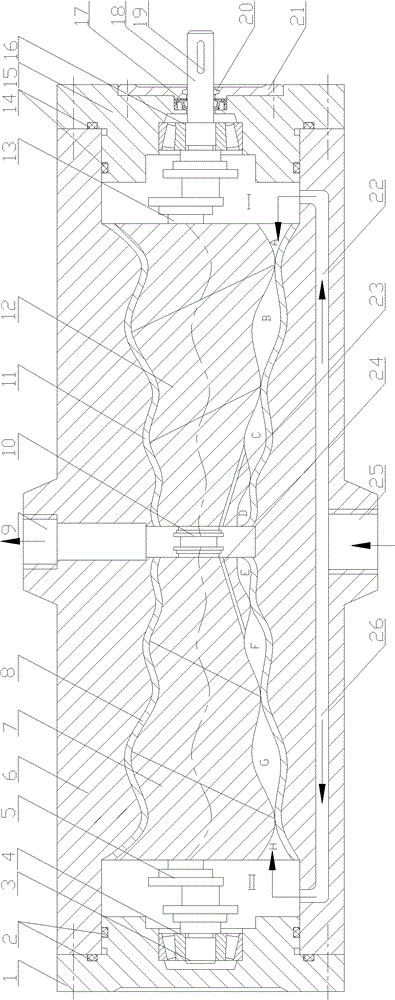

[0019] Invented a double-cone opposed cone-screw high-pressure seawater hydraulic pump, including a left end cover 1, a left O-ring seal 2, a shaft 3, a left tapered roller bearing 4, a left universal joint coupling 5, and a metal shell 6 , Left taper screw 7, left bushing 8, middle universal joint coupling 10, right bushing 11, right taper screw 12, right universal joint coupling 13, right O-ring 14, right end cover 15. Right tapered roller bearing 16, FB type rotary shaft lip seal ring 17, drive shaft 18, flat key 19, felt seal ring 20, small end cover 21.

[0020] The right end of the transmission shaft 18 is connected to the motor through the flat key 19 on the transmission shaft 18. The left end of the transmission shaft 18 is connected to the right end of the right universal joint coupling 13, and the small end cover 21 is installed on the transmission shaft 18 and is connected to the transmission shaft. 18 The clearance fit is sealed by the felt seal ring 20, the small end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com