Dual output inner rotor non-conical gear hydraulic motor

A non-conical gear, hydraulic motor technology, applied in the direction of rotary piston engine, rotary or swing piston engine, machine/engine, etc., can solve the problem that the configuration of oil inlet and outlet is easy to interfere with the installation position, affecting the displacement and output of hydraulic motor The problems of torque, planetary gear size and transmission ratio limitation can eliminate the phenomenon of trapped oil, increase the life and improve the strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

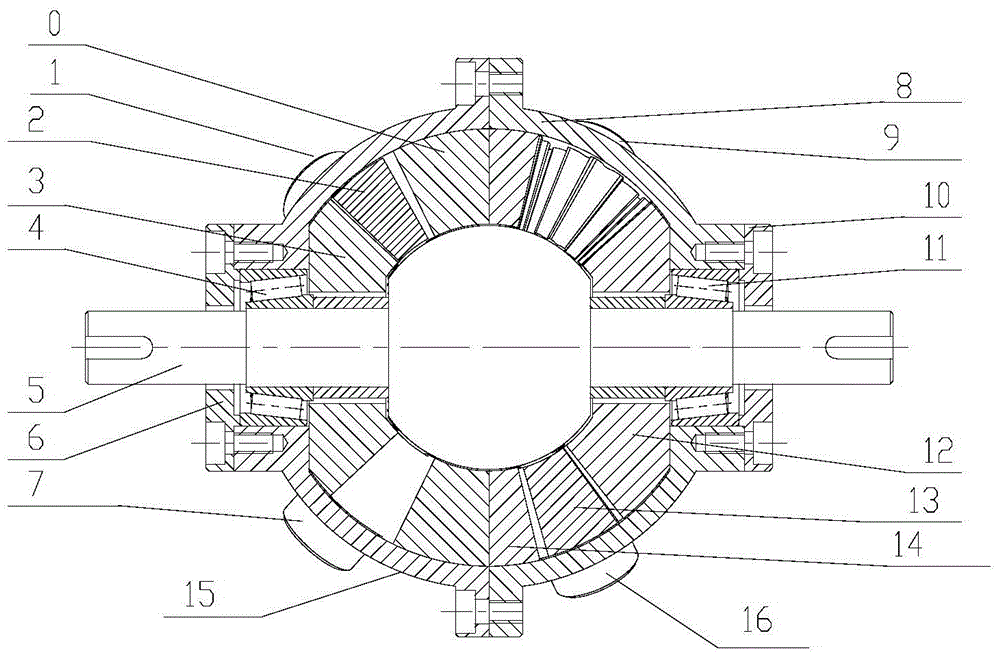

[0040] Such as figure 1 As shown, the double-output inner rotor non-conical gear hydraulic motor includes a housing, the housing includes a left housing 15 and a right housing 8, and the two housings are fastened by bolts;

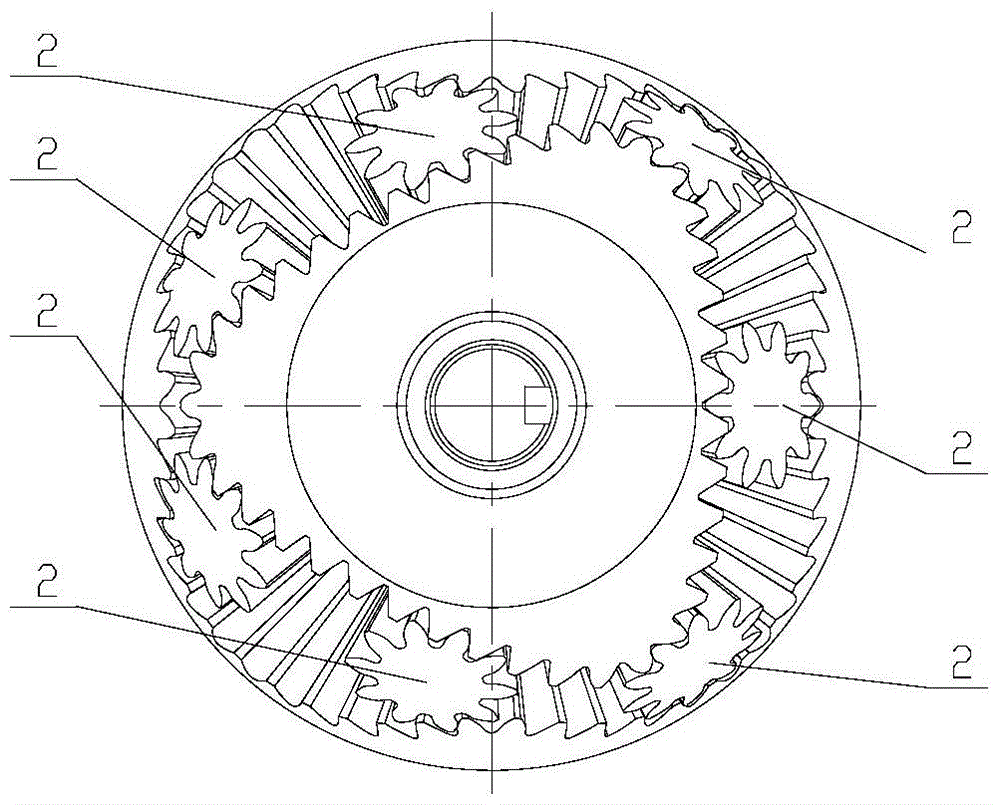

[0041] The left end cover 6 is installed outside the left end of the left housing 15, and the left end cover 6 presses the outer ring of the left bearing 4, and the inner ring of the left bearing 4 is in interference fit with the left shoulder of the output shaft 5; The left outer non-conical gear 3 is installed with the inner spherical surface positioning.

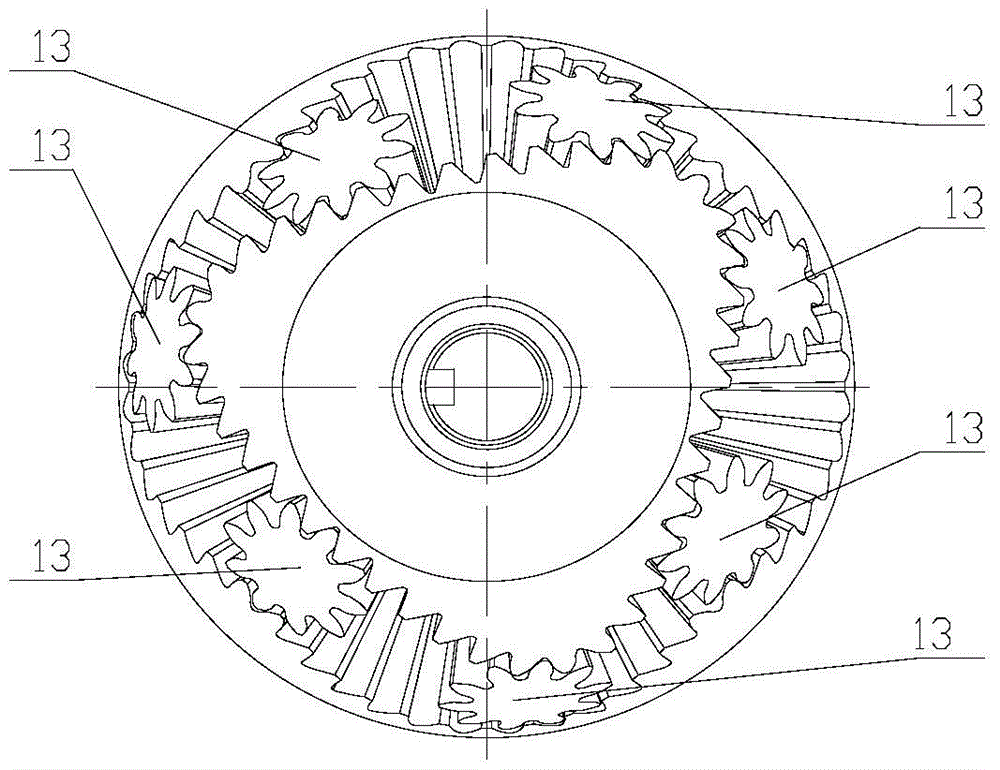

[0042] The right end cover 10 is installed outside the right end of the right housing 8, and the right end cover 10 presses the outer ring of the right bearing 11, and the inner ring of the right bearing 11 is installed and fixed on the right shoulder of the output shaft 5; The right outer non-conical gear 12 is installed with the inner spherical surface positioning. The right outer non-conical gear...

specific Embodiment approach 3

[0048] Such as figure 1 As shown, the double-output inner rotor non-conical gear hydraulic motor includes a housing, the housing includes a left housing 15 and a right housing 8, and the two housings are fastened by bolts;

[0049] The left end cover 6 is installed outside the left end of the left housing 15, and the left end cover 6 presses the outer ring of the left bearing 4, and the inner ring of the left bearing 4 is in interference fit with the left shoulder of the output shaft 5; The left outer non-conical gear 3 is installed with the inner spherical surface positioning.

[0050] The right end cover 10 is installed outside the right end of the right housing 8, and the right end cover 10 presses the outer ring of the right bearing 11, and the inner ring of the right bearing 11 is installed and fixed on the right shoulder of the output shaft 5; The right outer non-conical gear 12 is installed with the inner spherical surface positioning. The right outer non-conical gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com