Double-arc gear pump

A linear gear and double-arc technology, applied in the field of double-arc linear gear pumps, can solve problems such as gear pump output flow fluctuations and increased radial leakage at gear meshing, achieving stable operation, improving stability, and eliminating difficulties The effect of the oil phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be described in further detail below.

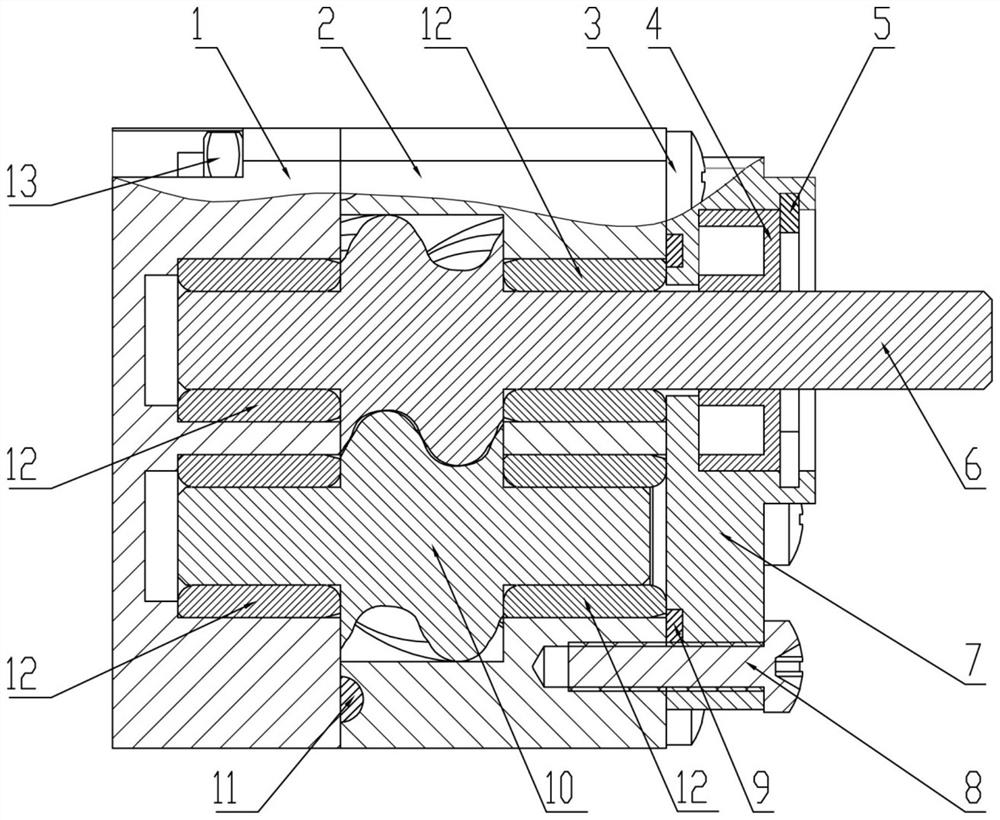

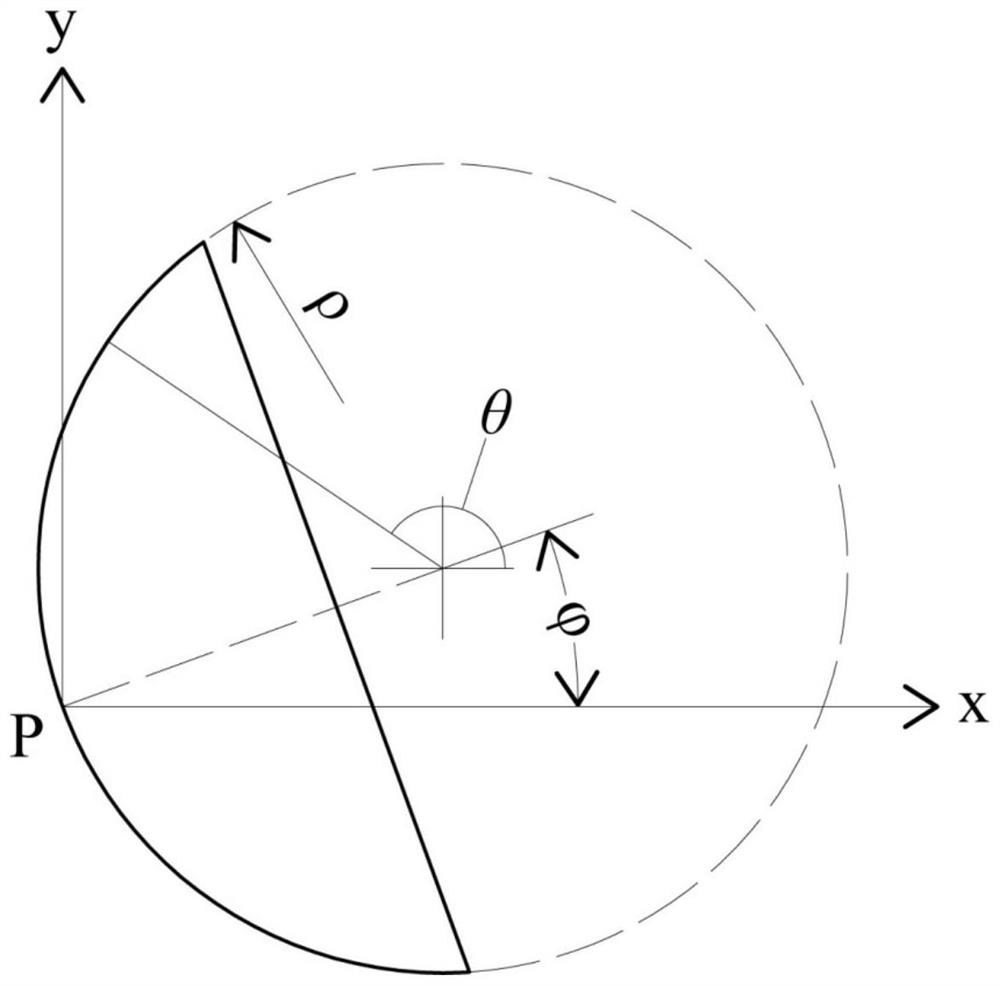

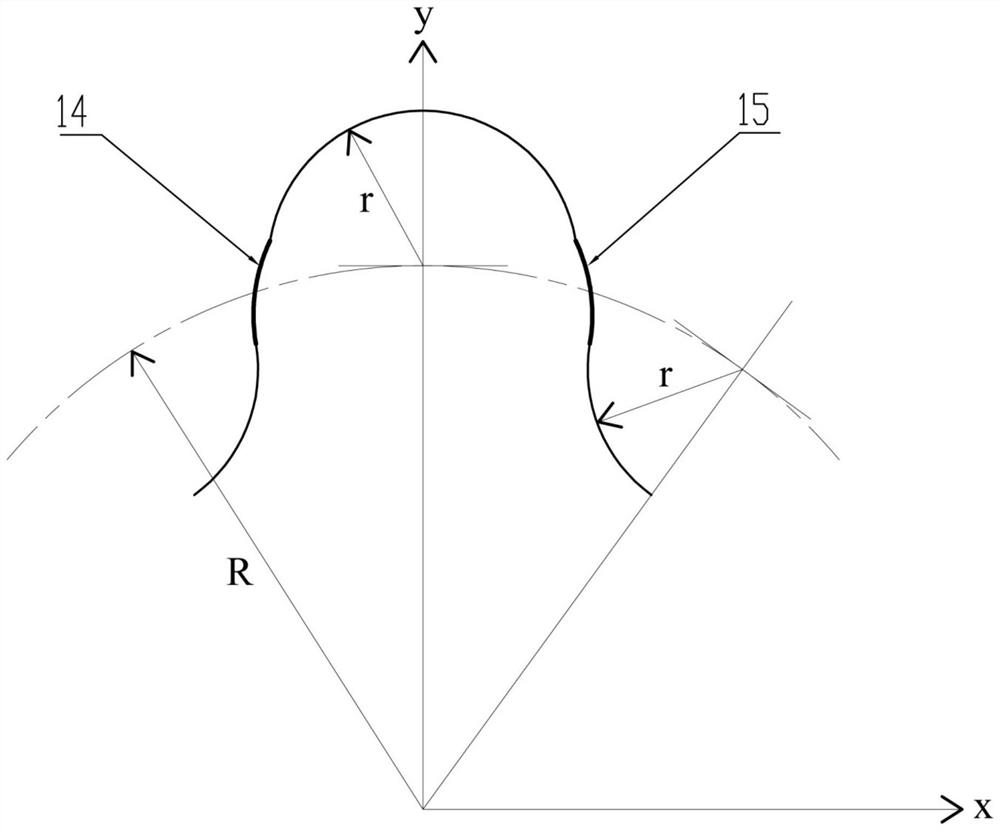

[0063] Such as figure 1 , Figure 5 As shown, a double circular arc gear pump, the overall structure is a common three-piece type, mainly composed of bearing box 1, pump body 2 and end cover 7, including bearing box 1, pump body 2, bolts 3, Oil seal 4, circlip 5, active double circular arc gear 6, end cover 7, Phillips screw 8, second sealing ring 9, driven double circular arc gear 10, first sealing ring 11, sliding bearing 12, hexagonal nut13. Among them, the active double-arc gear 6 and the driven double-arc gear 10 are both double-arc gears whose tooth tops and dedendums are arc-shaped, and the schematic diagram of the end surface meshing state of the double-arc gear pair is shown in Figure 4shown. The active double-arc gear 6 and the driven double-arc gear 10 are installed on the pump body 2, and the right and left ends of the active double-arc gear 6 and the driven double-arc gear 10 are provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com