Water boiler with liquid level stabilizing function

A technology of stable liquid level and water boiler, applied in fluid heaters, lighting and heating equipment, etc., can solve the problems of low water level control accuracy, large water level fluctuation range, unstable water output flow, etc., and achieve boiling water output temperature and water flow The output flow is stable, the water level fluctuation range is reduced, and the water level control accuracy is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

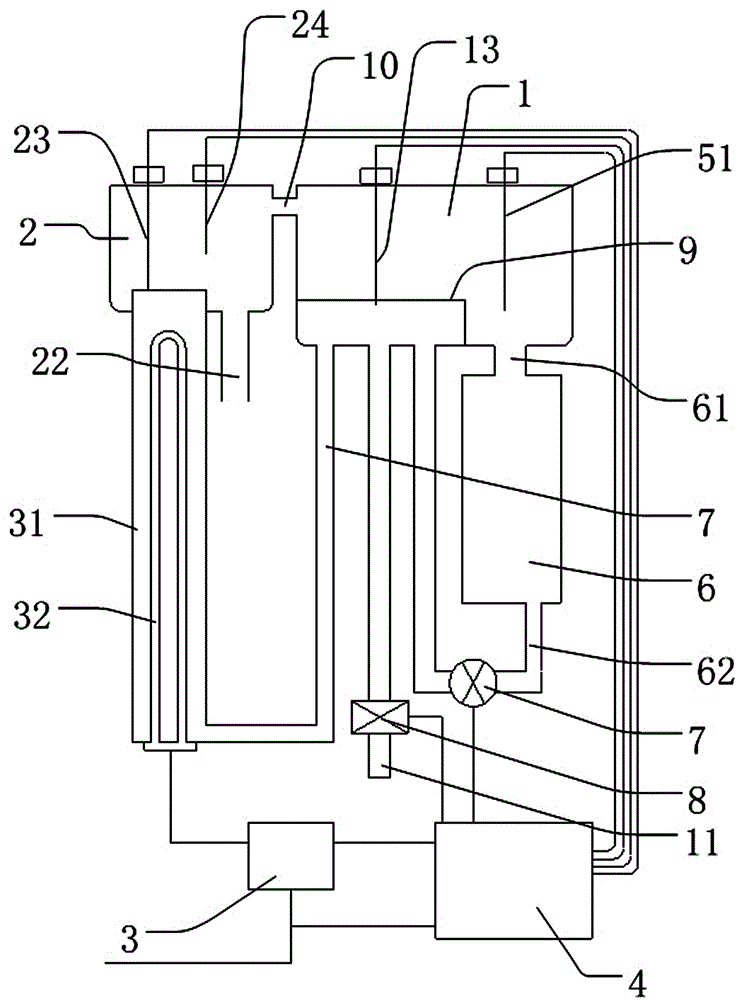

[0043] Such as figure 1 It is a schematic structural diagram of Embodiment 1 of the present invention. The figure shows a water boiler with liquid level stabilization function, including:

[0044] A cold water tank 1 for storing cold water;

[0045] One boiling water tank 2 for storing boiling water;

[0046] A heating pipe 32 for connecting the cold water tank and the boiling water tank;

[0047] The cold water tank 1 is provided with a cold water tank inlet pipe 11 and a cold water tank outlet pipe 12;

[0048] The boiling water tank 2 is provided with a boiling water tank inlet pipe (not shown) and a boiling water tank outlet pipe 22;

[0049] One end of the heating pipe 32 is connected to the cold water tank outlet pipe 12, and the other end is connected to the boiling water tank inlet pipe (not shown);

[0050] A heater 31 is provided in the heating pipe 32 for heating the water in the heating pipe 32;

[0051] An inlet valve 8 is provided on the cold water inlet pipe 11;

[0052] An o...

Embodiment 2

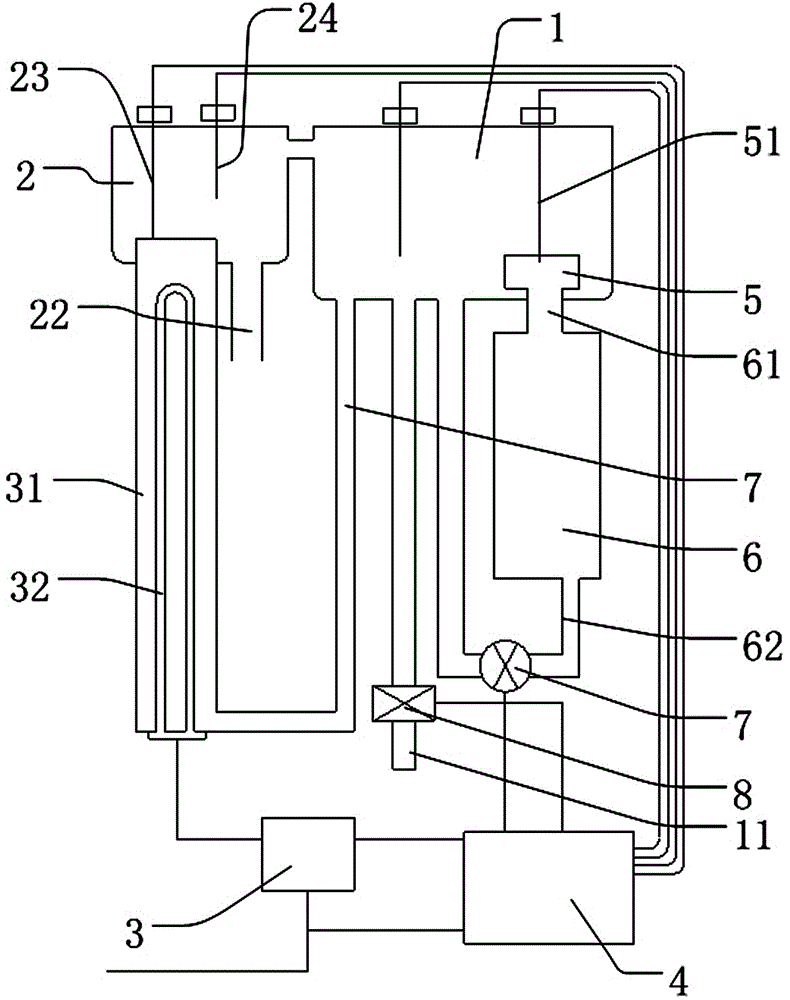

[0070] figure 2 Is a schematic structural diagram of Embodiment 2 of the present invention, such as figure 2 As shown, most of the technical solutions of the second embodiment are the same as those of the first embodiment. The difference technical feature is that the water boiler with liquid level stabilization function also includes a slow flow tube 5, the nozzle of the slow flow tube 5 is high At the bottom of the cold water tank 1, the slow flow chamber 6 is connected to the slow flow pipe 5 through a slow inflow water pipe 61, and the slow outflow water pipe 62 is connected to the bottom of the cold water tank 1. The slow flow pipe 5 is located inside the cold water tank 1.

[0071] After the water level in the cold water tank 1 reaches a certain height (that is, the height of the upper end of the slow flow pipe 5), the water flows out from the upper end of the slow flow pipe 5, flows into the slow flow chamber 6 through the slow inflow water pipe 61, and then flows through ...

Embodiment 3

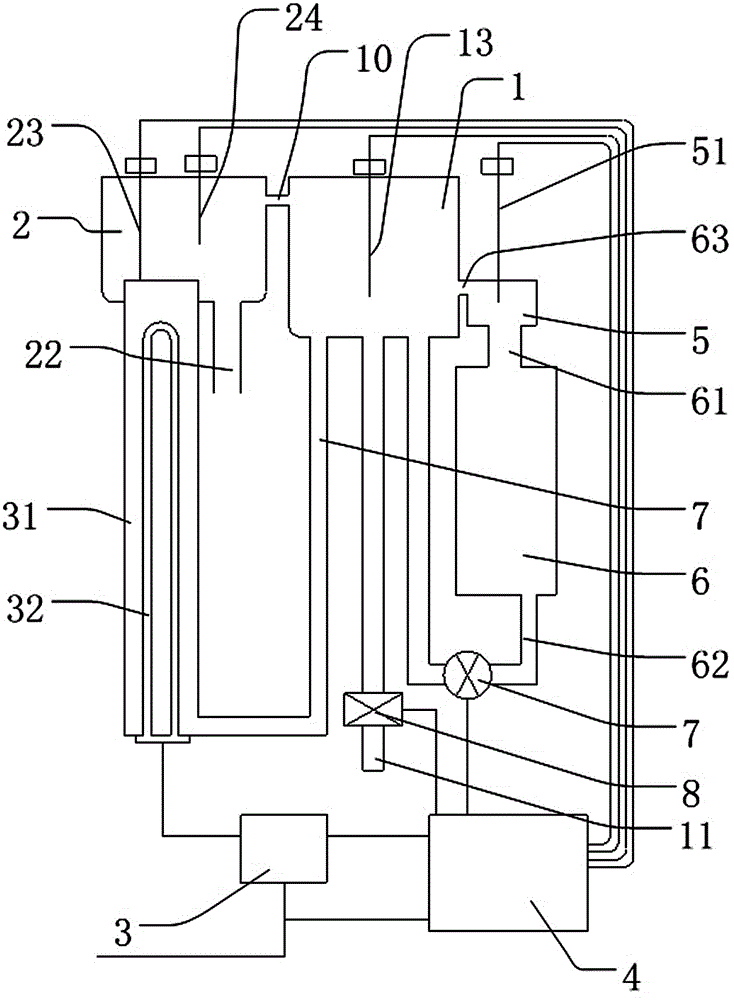

[0075] image 3 It is a schematic diagram of the structure of Embodiment 3 of the present invention, such as image 3 As shown, most of the technical solutions of the third embodiment are the same as those of the second embodiment. The different technical feature is that the slow flow tube 5 is located outside the cold water tank 1, and the slow flow tube 5 is connected to the cold water tank 1 through a slow flow conduit 63. The implementation and technical effects of Example 3 are basically the same as those of Example 2. After the water level in the cold water tank 1 reaches a certain height (that is, the nozzle height of the slow flow duct 63 on the side wall of the cold water tank 1), the water flows from the slow flow duct 63 flows into the slow flow pipe 5, flows into the slow flow chamber 6 through the slow inflow water pipe 61, and then flows back to the cold water tank 1 through the slow outflow water pipe 62. After so many cycles, the water pump 7 provides circulatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com