A solid gas starter

A starter and solid technology, applied in the direction of gas turbine devices, jet propulsion devices, machines/engines, etc., can solve the problems of turbine shaft wear, turbojet engine damage, overburning or damage, etc., to achieve stable gas output flow and improve gas Effects of cleanliness and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

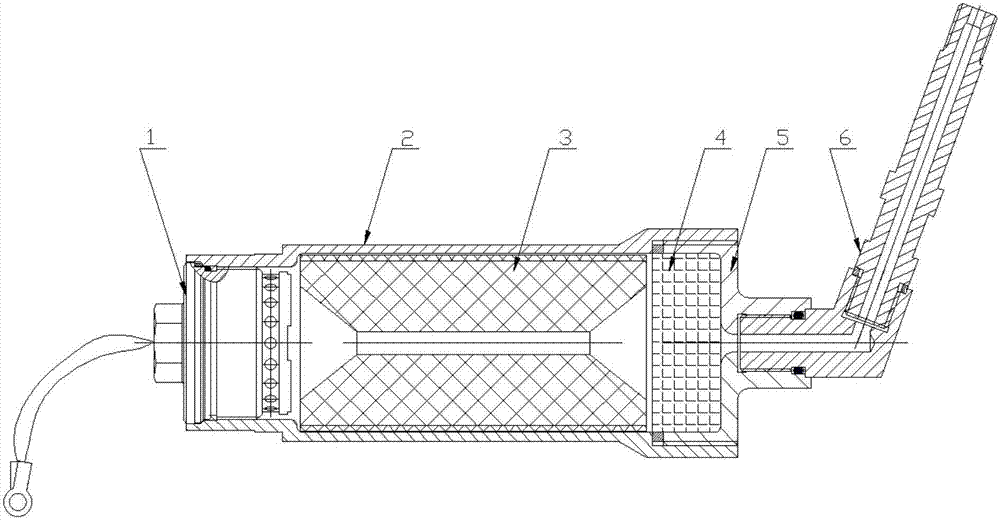

[0021] The solid gas starter is composed of an ignition device 1, a combustion chamber 2, a powder charge 3, a filter screen 4, a sealing head 5 and a gas pipeline 6. The igniter 1 adopts a double-bridge ignition circuit, is threadedly connected with the combustion chamber 2, and adopts a double-layer sealing structure of a copper gasket and an o-ring. The fire outlet of the igniter 1 is packaged with a thin aluminum sheet with a thickness of 0.1mm. The combustion chamber 2 is made of 30CrMnSi material, which is threadedly connected with the head 5 and sealed with a copper gasket. Charge 3 adopts double-base propellant, unsaturated polyester coating layer, the drug type is a combustion structure with tapered holes at both ends, and is freely filled in combustion chamber 2. The theoretical combustion temperature of the double-base propellant is less than 2200K, and the particle size of the residue is less than 20 μm. The filter screen 4 adopts molybdenum wire to be molded into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com