Resin quantitative replacement device

A technology of resin and plunger pumps, which is applied to casting molding equipment, molds, cores, etc. It can solve the problem of unstable resin addition and achieve the effect of preventing resin oxidation and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

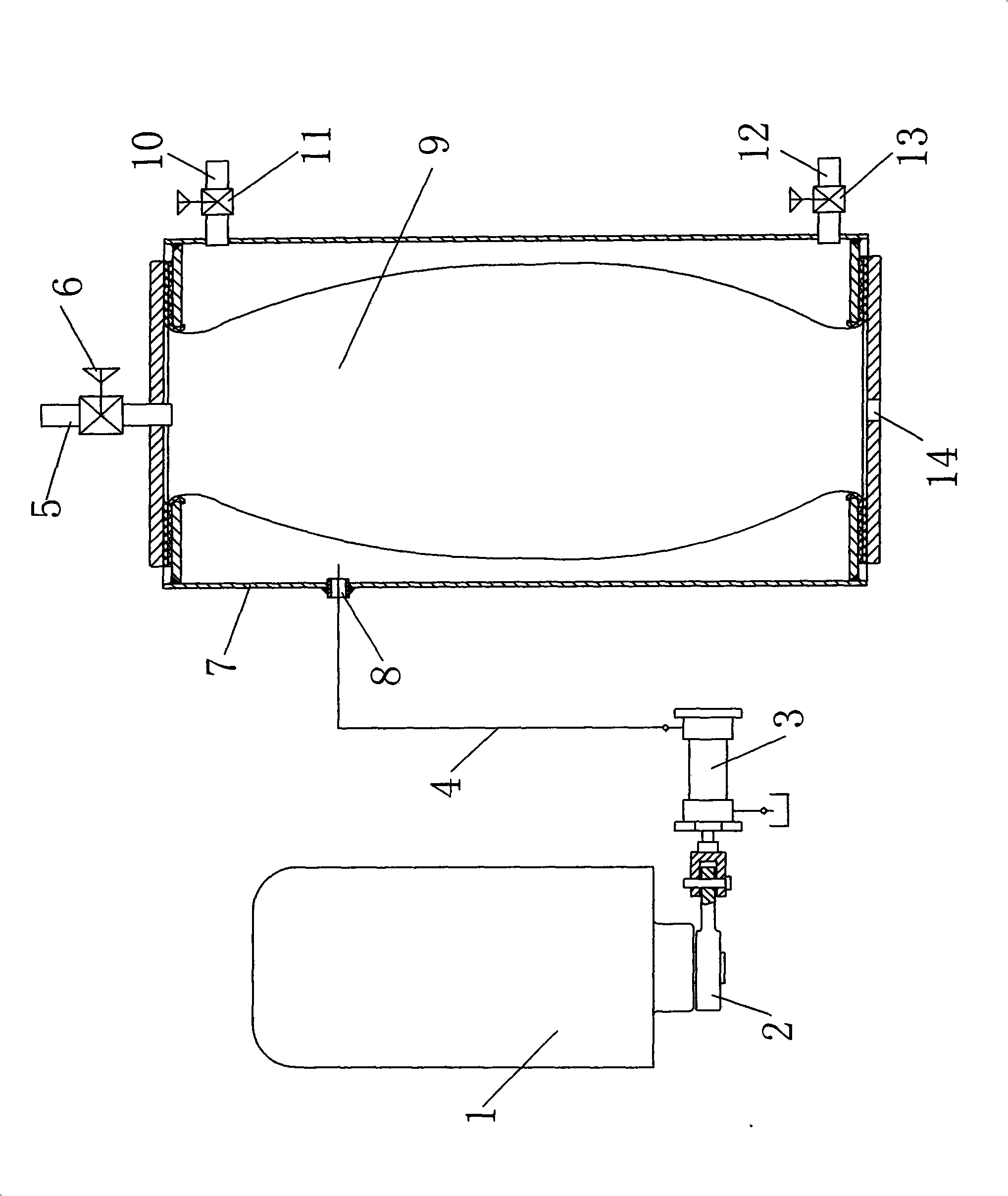

[0011] As shown in the drawings, the quantitative resin replacement device of the present invention includes a speed-regulating motor 1 , a plunger pump 3 and a replacement tank 7 . Capsule 9 is housed in the replacement tank 7, and the upper and lower ports of the capsule 9 are all sealed. The upper end of the replacement tank 7 is provided with a feed pipe 5 extending into the capsule 8, and the feed pipe 5 is provided with a ball valve 6. Feed pipe 5 is connected with resin original barrel during use. An oil filling port 8 and an upper oil discharge pipe 10 are provided on the upper side wall of the displacement tank 7 , and a ball valve 11 is provided on the upper oil discharge pipe 10 . A lower oil discharge pipe 12 is provided on the lower side wall of the displacement tank 7, and a ball valve 13 is provided on the lower oil discharge pipe 12. The bottom of the capsule 9 is provided with a resin output port 14 . The speed regulating motor 1 is connected with the plung...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com