Electric-hydraulic proportional plunger pump

A technology of electro-hydraulic proportional and plunger pumps, applied in variable capacity pump components, liquid variable capacity machines, pumps, etc., can solve the problems of easy vibration, energy waste, easy damage, etc., and increase the axial bearing capacity , the effect of high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

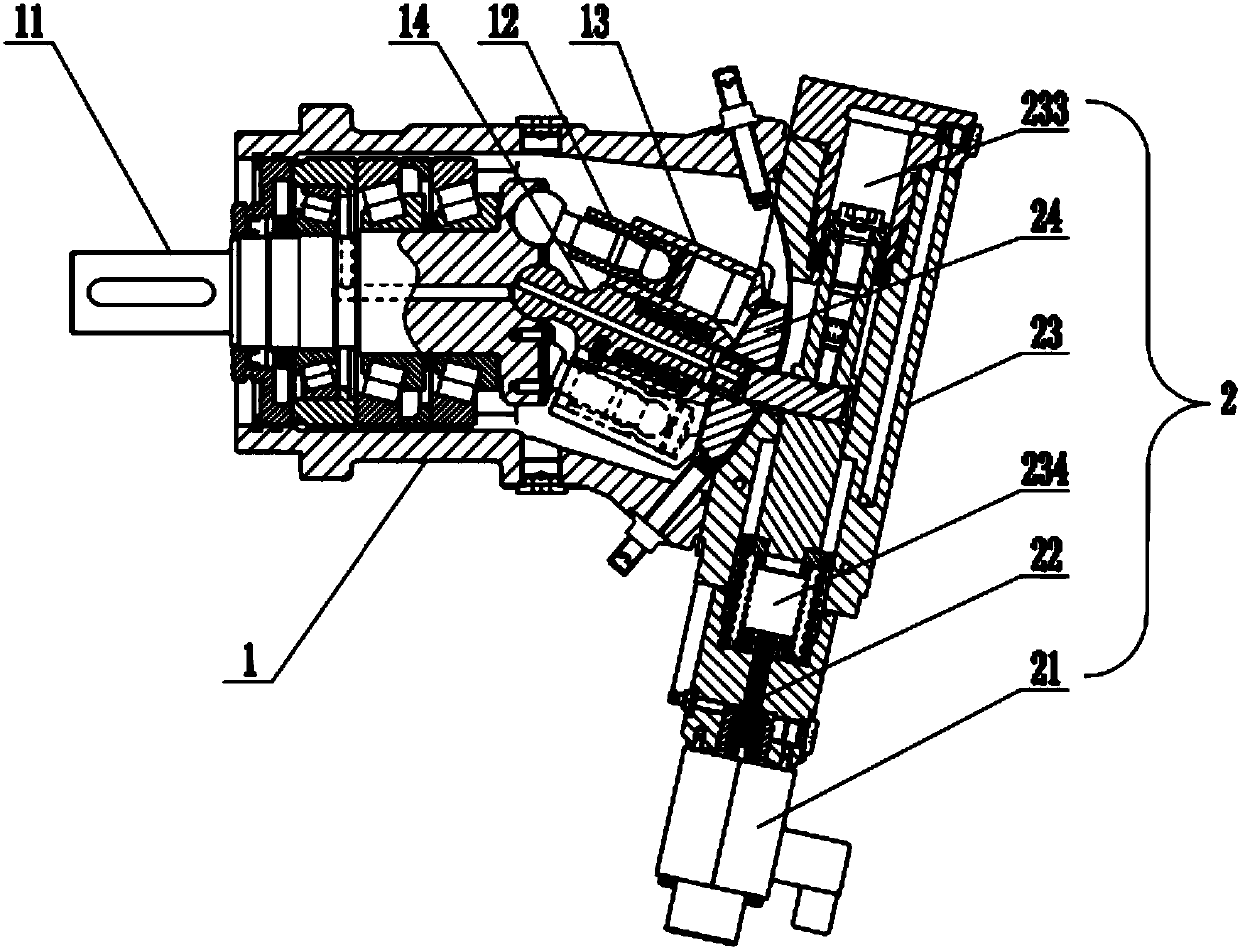

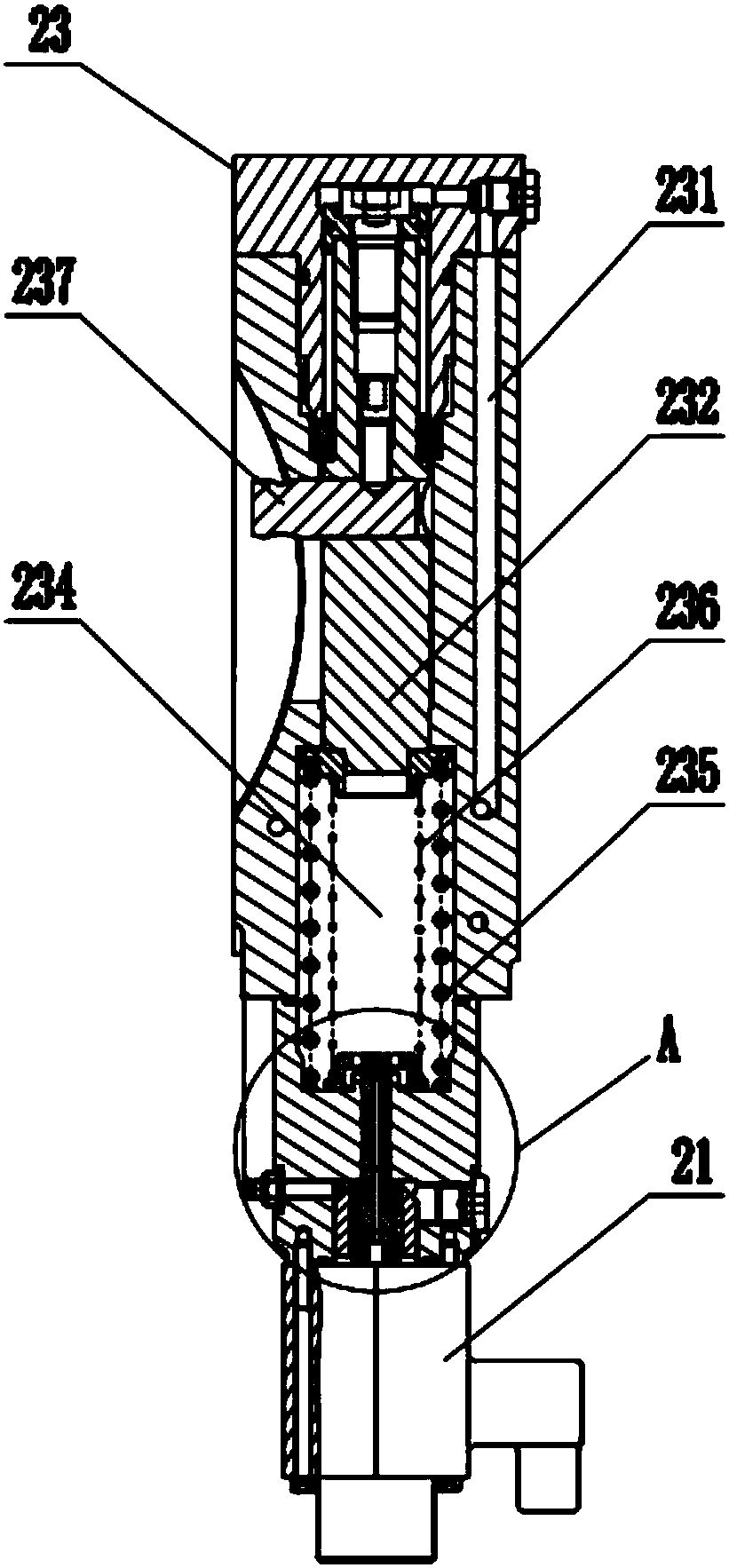

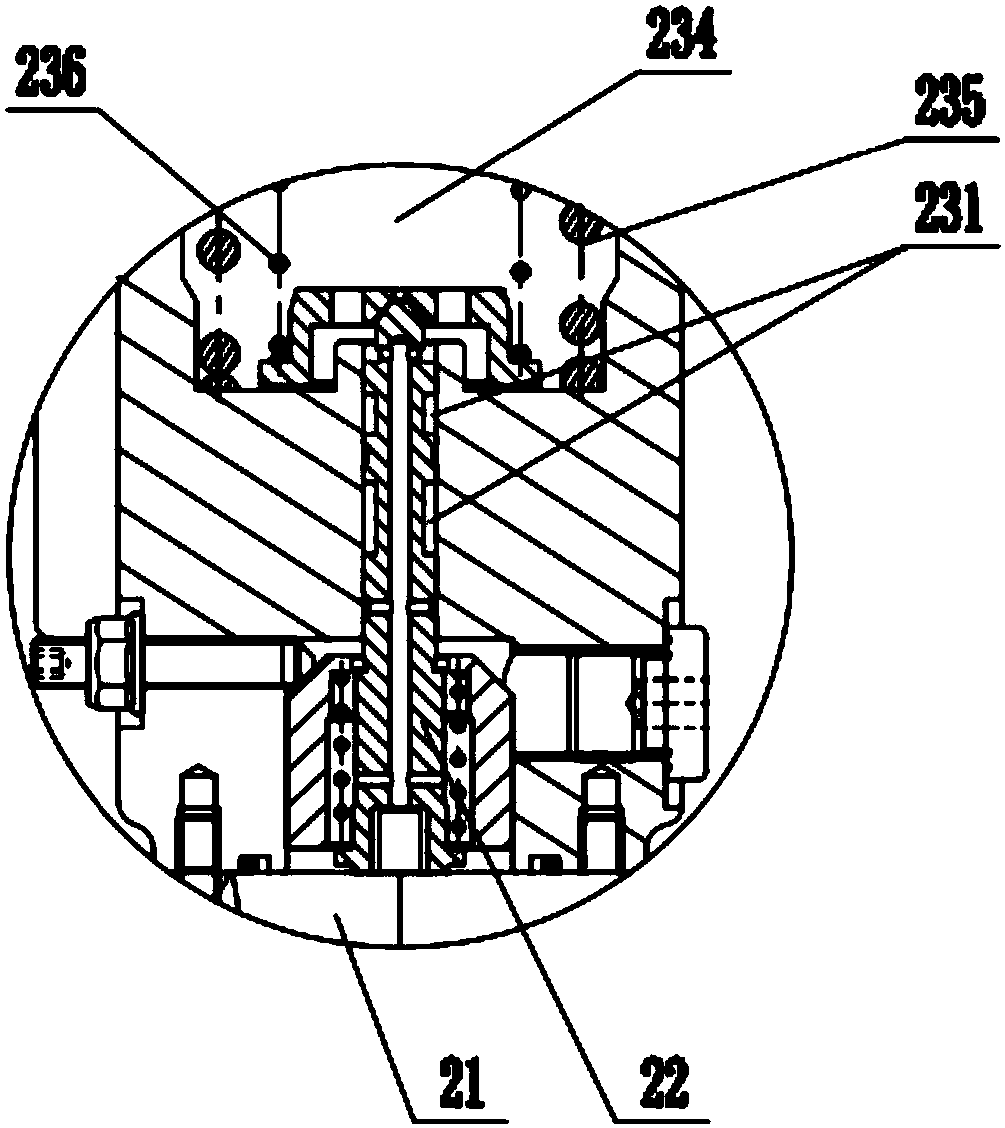

[0036] The specific embodiment of the present invention is as Figure 1 to Figure 6 As shown, an electro-hydraulic proportional plunger pump includes a plunger pump main body 1 and a control device 2 for adjusting the displacement of the pump. Wherein, the plunger pump main body 1 includes a bearing 11 and a central rod 14 for connecting the bearing 11 and the control device 2 and the axis forms an angle with the axis of the bearing 11. There are multiple ends connected to the bearing 11 around the central rod 14. The other end of the plunger 12 is provided with a plunger sleeve 124 and a cylinder body 13 matching the outer diameter of the plunger sleeve 124 in turn. This included angle causes the plunger 12 to rotate once around the center rod 14 When there is a stroke in the cylinder body 13, the oil discharge and oil suction are realized by the back and forth of the stroke, and the adjustment of the included angle has just adjusted the displacement of the pump; the control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com