Single-compartment ball mill type cement vertical mill grinding device

A cement and single-silo technology, applied in the field of cement crushing, can solve the problems of low grinding efficiency, low operation rate, and increased power consumption, so as to reduce the power consumption of grinding, stabilize the flow of raw materials, and increase the total power consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

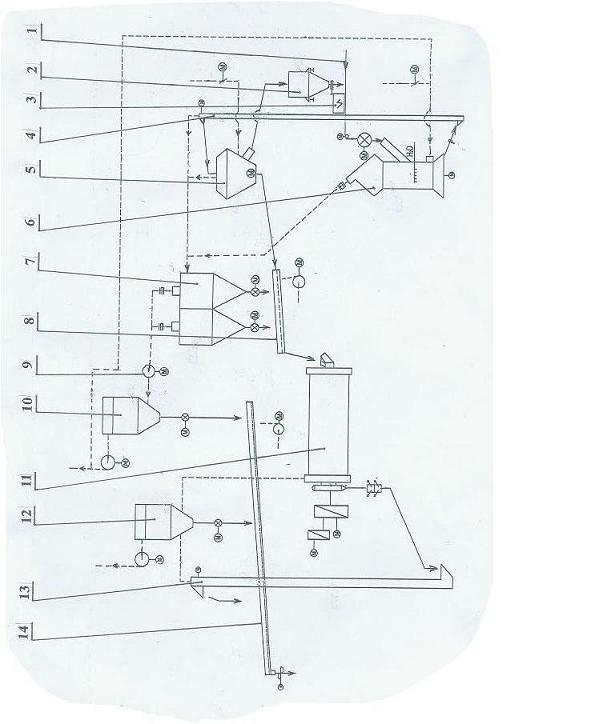

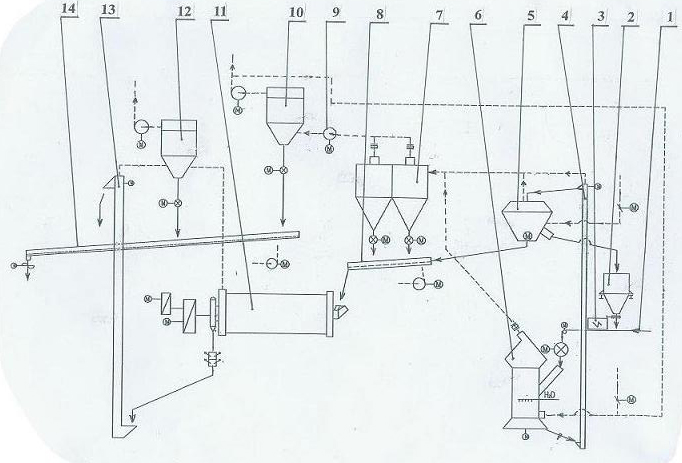

[0010] The accompanying drawings disclose a specific embodiment of the present invention in a non-limiting manner, which will be further described as follows in conjunction with the accompanying drawings.

[0011] The single-chamber ball mill type cement vertical mill grinding device of the present invention includes a raw material conveyor belt 1, an iron remover 3, a cement vertical mill 6, a first hoist 4, a fine powder separator 7, a first dust collector 10, and a semi-finished product conveyor The chute 8, the single-chamber fine grinding ball mill 11, the second elevator 13, the second dust collector 12, the finished product delivery chute 14, also includes a coarse powder circulation device 5, which is connected in series with the cement Between the discharge port of the vertical mill 6 and the feed port of the single-chamber fine grinding ball mill 11, the connection relationship is: the feed port of the coarse powder circulation device 5 is connected with the discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com