Method for improving use reliability of lubricating system for 5M rolling mill stand roll

A technology of lubrication system and rolling mill frame, which is applied in the direction of engine lubrication, roll safety equipment, and lubricating parts, etc. It can solve problems such as bearing burnout, poor lubrication, and economic losses in export racks, and achieve improved lubrication, The effect of reducing the failure of the rack roll and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

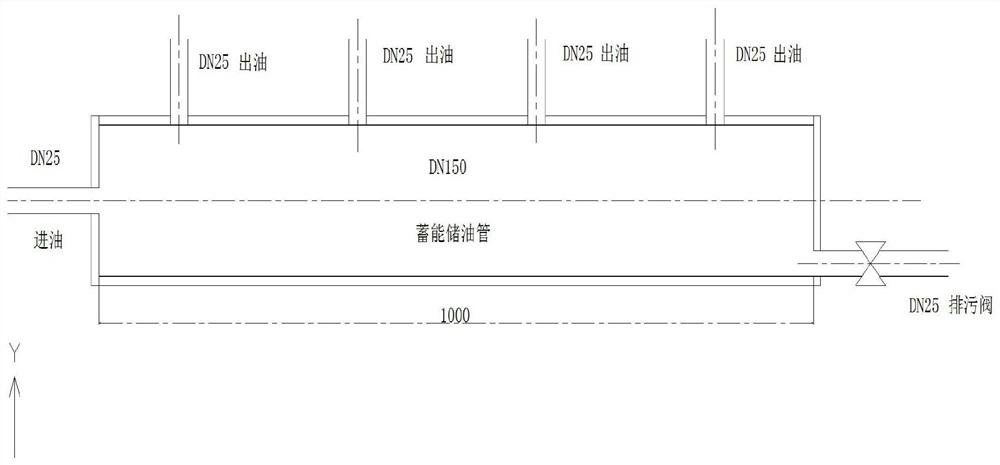

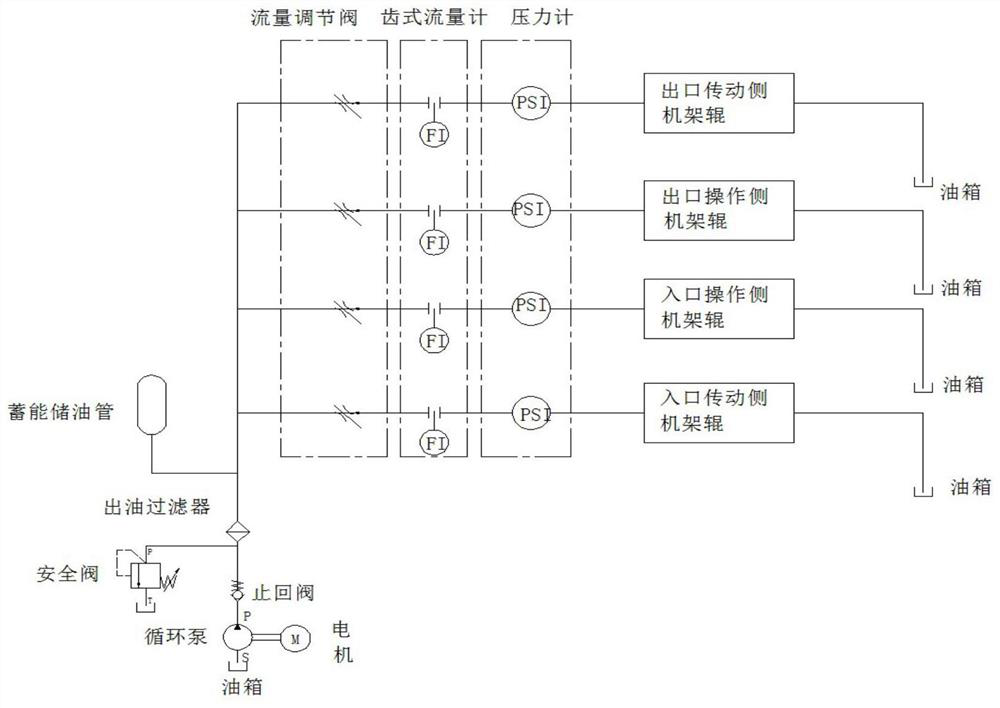

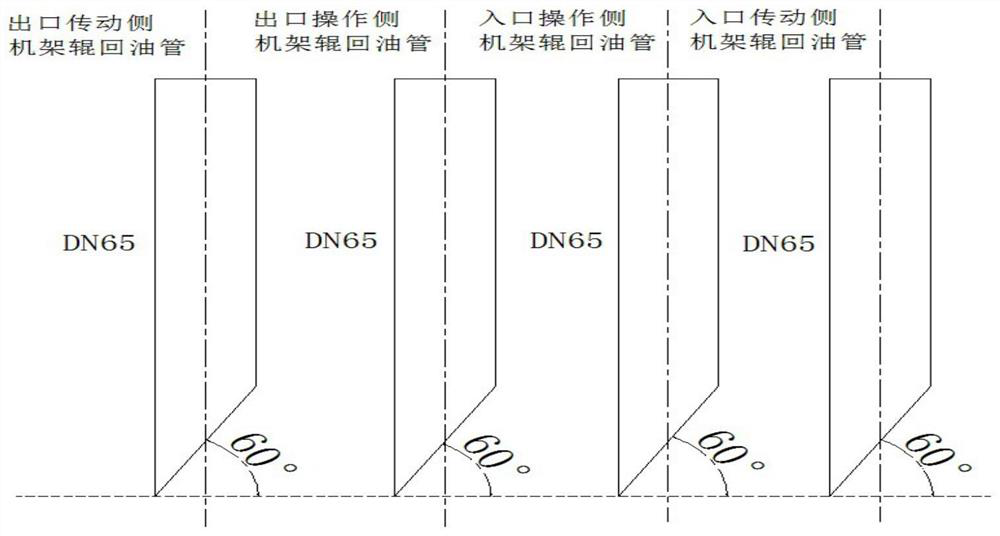

[0018] This embodiment provides a method for improving the reliability of the lubricating system of the stand rolls of a 5M rolling mill, canceling the four-out and one-turn structure of the original lubricating system pipeline, and changing it to four in and four out, that is, by analyzing the mechanical structure of the stand rolls and Rack roll lubrication system, analyze the problems existing in the original lubrication system, transform the piping of the rolling mill rack roll lubrication system, divide the original pipeline into 4 branch pipes to lubricate the 4 rack roll user points, and finally 4 The road branch pipes are collected to the main pipe and returned to the fuel tank, and only the main pipe is set for pressure monitoring, and the user points of the four rack rollers are changed to set up independent circuits for lubrication. The circuits do not affect each other, and each circuit is equipped with a flow meter and a pressure sensor separately. , to realize rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com