Bolt type gas pressure reducing and regulating pipe

A bolt type, pressure regulating pipe technology, applied in the direction of pipe components, pipes/pipe joints/pipe fittings, functional valve types, etc. The effect of unstable flame state, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

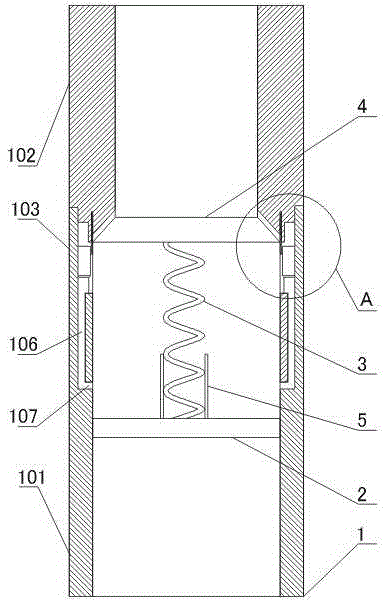

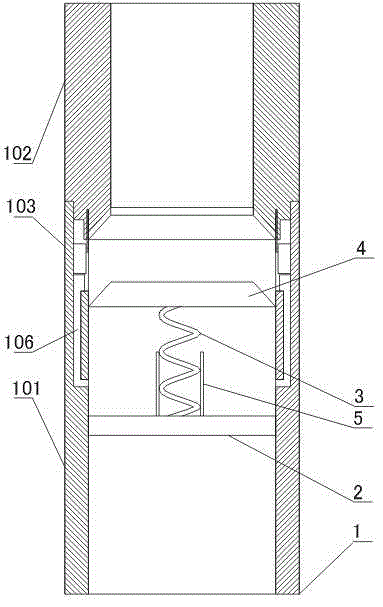

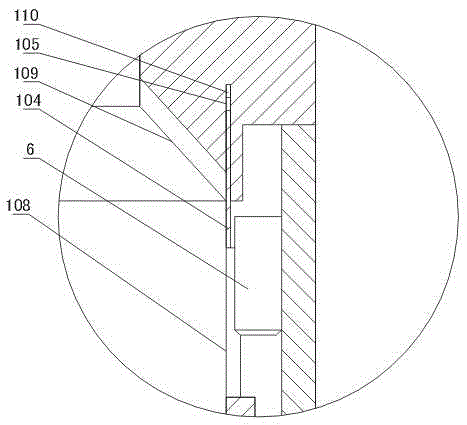

[0043] Such as figure 1 and Figure 5 As shown, the bolted gas decompression and pressure regulating pipe includes: a pipe body 1, the pipe body 1 includes a low-pressure section 101 and a high-pressure section 102, the inner diameter of the high-pressure section 102 is smaller than the inner diameter of the low-pressure section 101, and one end of the low-pressure section 101 is provided with an outer Ring 103 and the inner ring 104 flush with the inner surface of the low-pressure section 101, the inner surface of the outer ring 103 is provided with an internal thread, one end of the high-pressure section 102 is provided with an internal thread that is threadedly connected with the outer ring 103, and the end of the high-pressure section 102 There is also an annular groove 105 for accommodating the inner ring 104; a fixed body 2, the fixed body 2 is arranged in the low-pressure section 101 and connected with the inner surface of the low-pressure section 101, and the fixed bod...

Embodiment 2

[0049] Such as figure 1 and image 3 As shown, this embodiment further describes the fixed body 2 on the basis of the embodiment 1. The fixed body 2 is a porous plate.

[0050] The holes on the fixed body 2 are used for gas to pass through.

Embodiment 3

[0052] Such as figure 1 and Figure 4 As shown, this embodiment further describes the fixed body 2 on the basis of the embodiment 1. The fixed body 2 includes a circular middle plate 201 and a connecting rod 202 evenly arranged on the outer surface of the circular middle plate 201, the connecting rod 202 is connected to the inner surface of the low-pressure section 101, and the spring 3 is connected to the circular middle Board 201 is connected.

[0053] The gaps between the connecting rods 202 are used for gas to pass through.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com