Pipe type fuel gas pressure-relief device

A decompression device, gas technology, applied in the direction of the valve device, safety valve, engine components, etc., can solve the problems of unstable flame state, turbulent natural gas flow, complex structure of the pressure reducing valve, etc., to avoid unstable flame state and cost Low, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

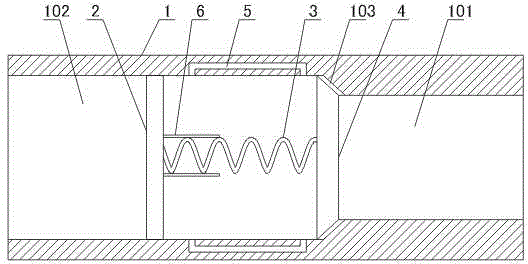

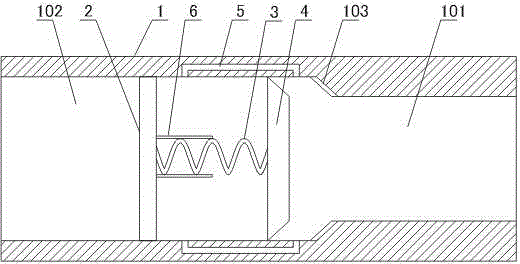

[0033] Such as figure 1 As shown, the tubular gas decompression device includes: a pipe body 1, two ends of the pipe body 1 are provided with connecting threads, and the space in the pipe body 1 is composed of a high-pressure chamber 101 and a low-pressure chamber 102; the inner diameter of the high-pressure chamber 101 is smaller than that of the low-pressure chamber The inner diameter of 102; fixed body 2, fixed body 2 is arranged in low-pressure chamber 102 and is connected with the inner surface of low-pressure chamber 102, and fixed body 2 is provided with the gap that passes through for gas; Spring 3, one end of spring 3 and fixed body 2 Connection; piston 4, piston 4 is connected with the other end of spring 3, spring 3 pushes piston 4 close to the end of high-pressure chamber 101; vent hole 5, vent hole 5 is evenly opened on the tube wall of low-pressure chamber 102, vent hole Both ends of 5 communicate with the inner space of the low-pressure chamber 102 , and the ven...

Embodiment 2

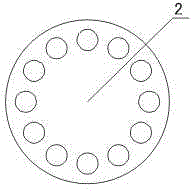

[0037] Such as figure 1 with image 3 As shown, this embodiment further describes the fixed body 2 on the basis of the embodiment 1. The fixed body 2 is a porous plate.

[0038] The holes on the fixed body 2 are used for gas to pass through.

Embodiment 3

[0040] Such as figure 1 with Figure 4 As shown, this embodiment further describes the fixed body 2 on the basis of the embodiment 1. The fixed body 2 includes a circular middle plate 201 and a connecting rod 202 evenly arranged on the outer surface of the circular middle plate 201. The connecting rod 202 is connected to the inner surface of the low-pressure chamber 102, and the spring 3 is connected to the circular middle Board 201 is connected.

[0041] The gaps between the connecting rods 202 are used for gas to pass through.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com