Drum mowing device of half-feed combine harvester

A combine harvester and semi-feeding technology, which is applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve problems such as troublesome replacement, easy grass entanglement, and potential safety hazards, and achieves convenient operation, fast crushing, and prevents The effect of chipping or breaking failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

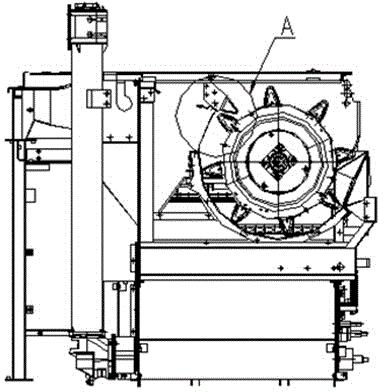

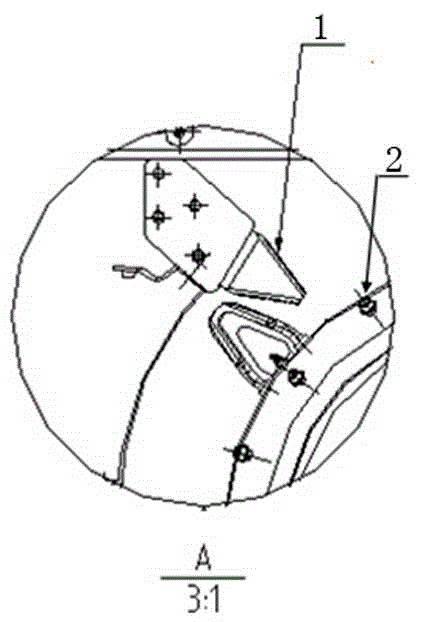

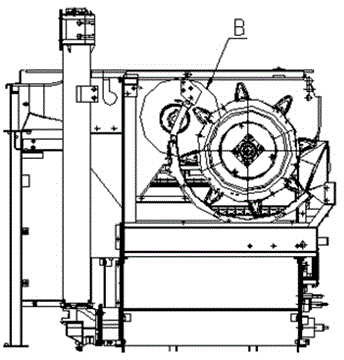

[0019] Such as image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 A kind of semi-feeding type combine harvester drum mower of the present invention shown, comprises support frame 1, is provided with six square ribs 3 between the two side walls of support frame 1 length direction, adjacent ribs 3 to form a blade hole position, a support shaft 9 is provided between the two side walls in the width direction of the support frame 1, and the two ends of the support shaft 9 are provided with a mounting seat 2, and the support shaft 9 is installed on the support frame through the mounting seat 2 1, ten blades 4 are installed on the supporting shaft 9, and the knife edges of the blades 4 correspond to the blade holes between the rib plates 3, and each blade 4 is fixed by two fixed seats 7 symmetrically arranged on both sides of the blade 4 On the support shaft 9, a shaft sleeve 8 is arranged on the support shaft 9 between adjacent blades 4; two sets of pins 6 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com