Cutting device and lawnmower with same

A cutting device and cutting blade technology, applied in cutters, harvesters, agricultural machinery and implements, etc., can solve the problems of limited storage cavity capacity, affecting cutting efficiency, etc., to prevent grass accumulation at the front end, high cutting efficiency, high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

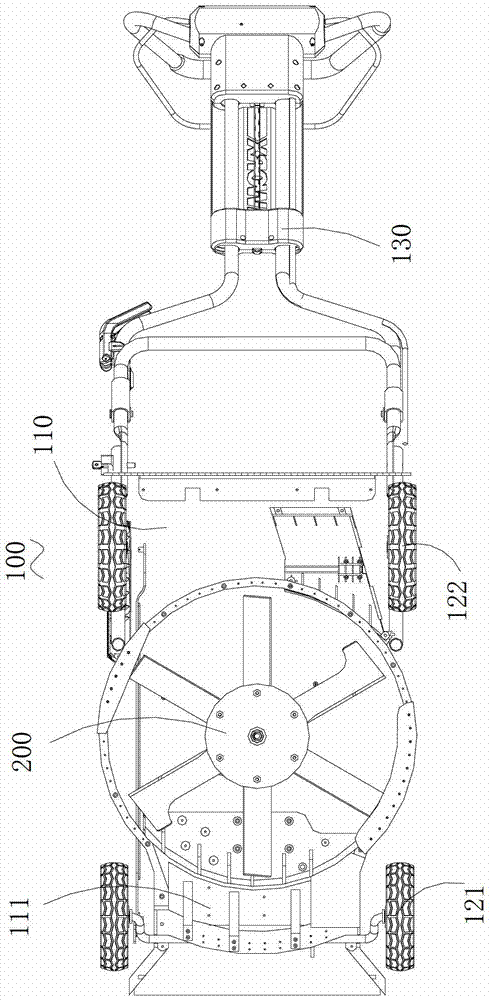

[0027] Please refer figure 1 In this embodiment, the lawn mower 100 has a housing 110, and a plurality of rollers are provided at the bottom of the housing 110 to support the lawn mower 100 to move on the ground. The rollers include a pair of front wheels 121 supporting the front casing 110 and a pair of rear wheels 122 supporting the rear casing 110. The front end of the casing 110 forms a cutting cavity 111 between the two front wheels 121. An operating mechanism 130 extending to the rear of the lawn mower 100 is connected to the rear of the casing 110 for controlling the operation of the lawn mower 100. A driving device is provided in the casing 110. Preferably, the driving device is a motor (not shown), the motor is connected with an output shaft, and the motor drives the output shaft to output rotational power. An energy unit for providing energy for the motor is provided in the housing 110. Preferably, the energy unit is a battery pack (not shown). The cutting device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com