Atomizer with mixed flue gas function

An atomizer and functional technology, applied in the field of electronic cigarettes, can solve the problems of insufficient fullness and limited length of electronic smoke, and achieve the effects of improving the overall sensory quality, making up for the lack of fullness, and overcoming the lack of fullness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

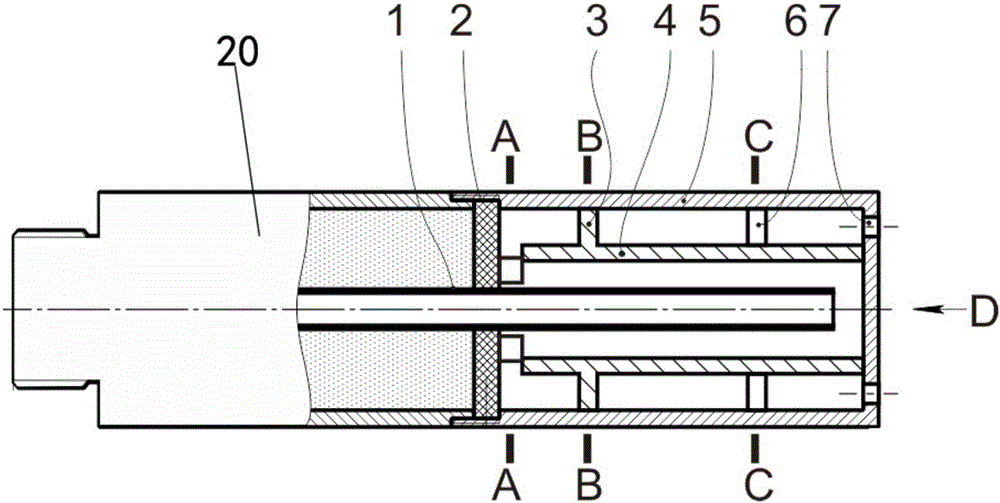

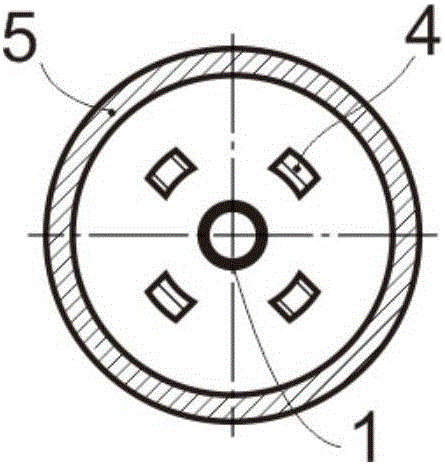

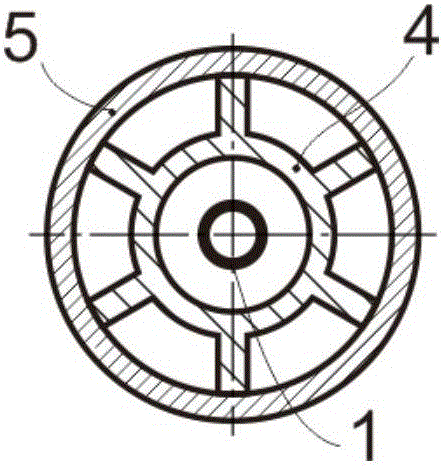

[0042] Figure 1-5 The atomizer shown with the function of mixing smoke includes an atomizer main body 20 and an air guide tube 1 which is arranged in the atomizer main body 20 and has one end protruding from the tail end 2 of the atomizer main body. The air guide tube 1 can also be Insert from the end 2 of the atomizer body;

[0043] It also includes a shell 5 installed on the tail end 2 of the atomizer body and the other end is closed, and an inner tube which is sleeved in the shell 5 and has one end in contact with the tail end 2 of the atomizer body and the other end in airtight contact with the closed end of the shell 5 4;

[0044] The air duct 1 extends to the closed end of the shell 5 and is spaced at a certain distance;

[0045] A first air flow channel is formed between the air guide tube 1 and the inner tube 4;

[0046] A second airflow channel is formed between the inner tube 4 and the outer shell 5;

[0047] The outer wall of the inner tube 4 is provided with t...

Embodiment 2

[0055]As a further improvement of Embodiment 1, such as Figure 6-10 As shown, wherein, the end of the inner tube 4 facing the atomizer main body 20 is provided with a connecting ring 8 detachably connected thereto, and the air guide hole is provided on the connecting ring 8 .

[0056] Further, the end of the inner tube 4 facing the closed end of the outer casing 5 is provided with an isolating ring 9 detachably connected thereto; the isolating ring 9 is provided with a radial spacer 10 to isolate its two sides, which is separated from the closed end of the outer casing 5 A mixing chamber is formed between them, and a ventilation hole communicating with the mixing chamber and the second air flow channel is provided on the spacer ring 9; the air outlet 7 is provided on the closed end of the shell 5 and can communicate with the mixing chamber and the outside world. The rest are basically the same as in Embodiment 1. Of course, only the connection ring 8 or the spacer ring 9 is ...

Embodiment 3

[0059] As a further improvement of Embodiment 2, such as Figure 11-15 As shown, wherein, the air guide tube 1 is covered with a plurality of annular plates 11 spaced a certain distance from the inner wall of the inner tube 4, and the rest of the structure is basically the same as that of the second embodiment. The annular plate 11 can further block the passing flue gas to form eddies and turbulent flows, further increasing the mixing speed of the flue gas.

[0060] In this embodiment, the air guide tube 1 is provided with a ring plate 11 on the entire outer wall of the shell 5. Obviously, only a small amount of ring plates 11 can be placed on the air guide tube 1; One or several ring plates 11 near the air outlet end are fixedly connected with the air duct 1, such as interference fit, bonding or heat bonding without residual odor, so as to ensure that each ring plate 11 will not be damaged during use, transportation, etc. Or the carrying state is separated from the air guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com