a removal device

A technology for rejecting devices and installation positions, applied in sorting and other directions, can solve problems such as affecting material transportation, reducing production efficiency, using costs, increasing energy consumption, etc., and achieves the effects of convenient use, convenient installation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

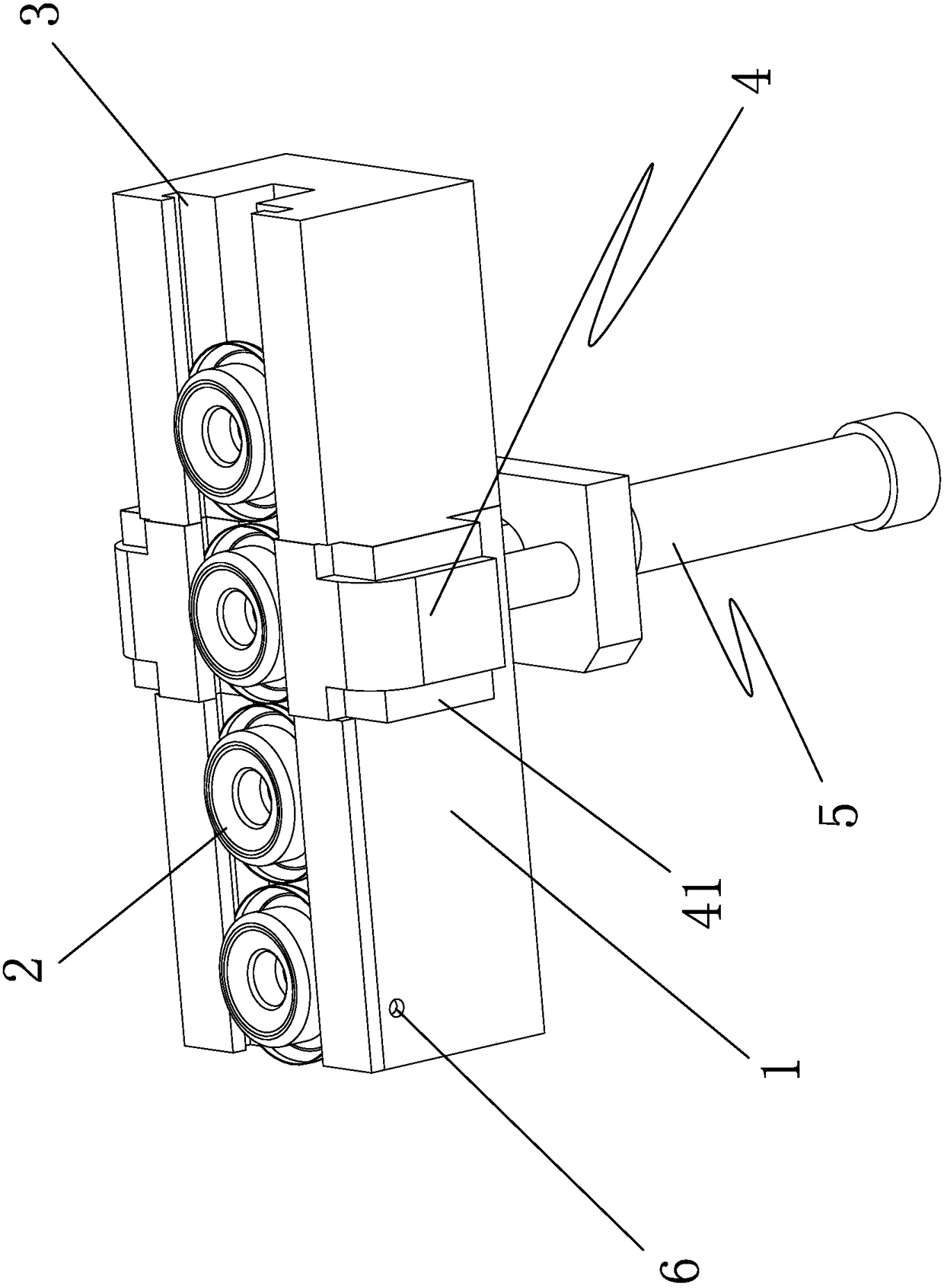

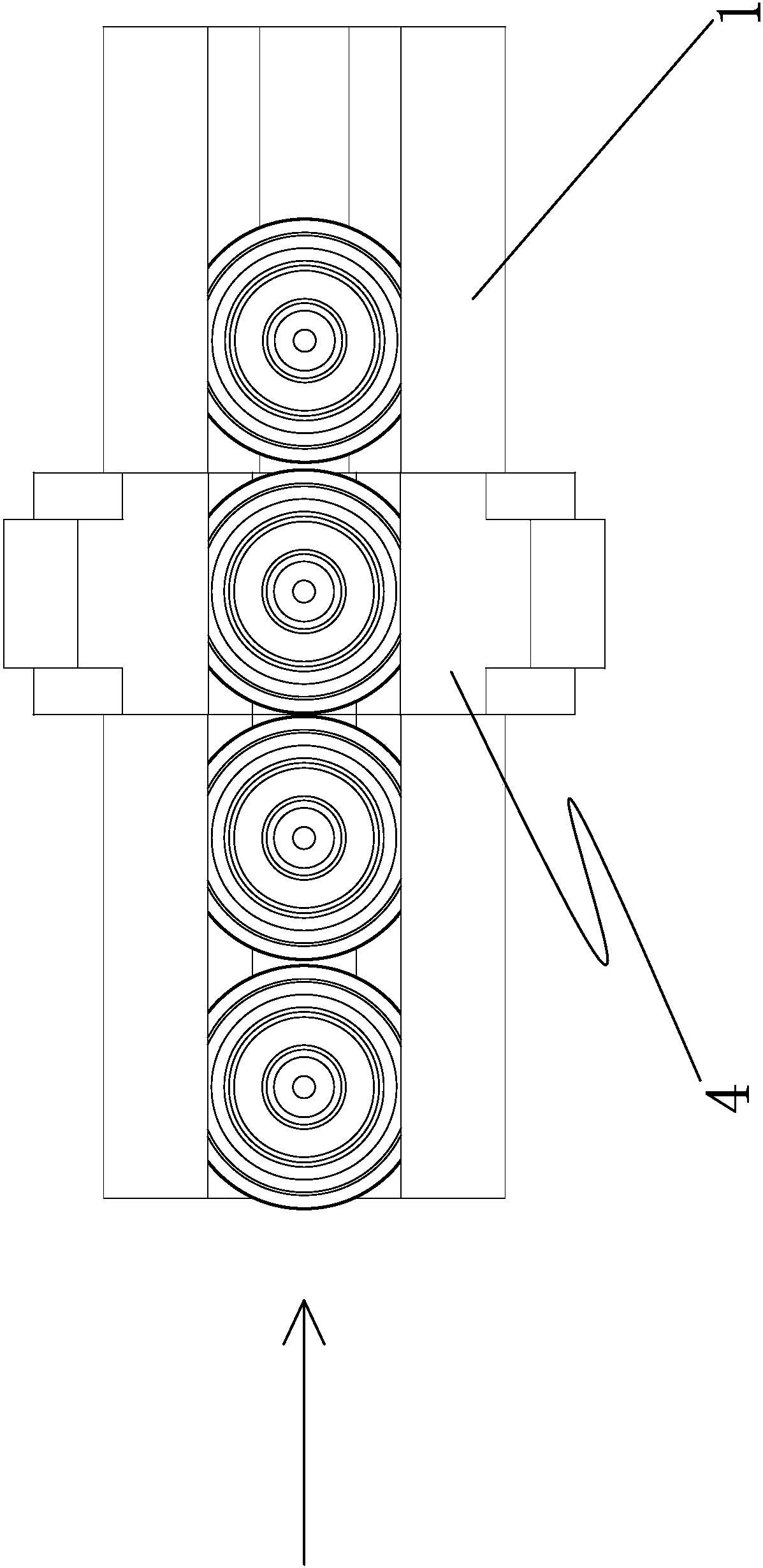

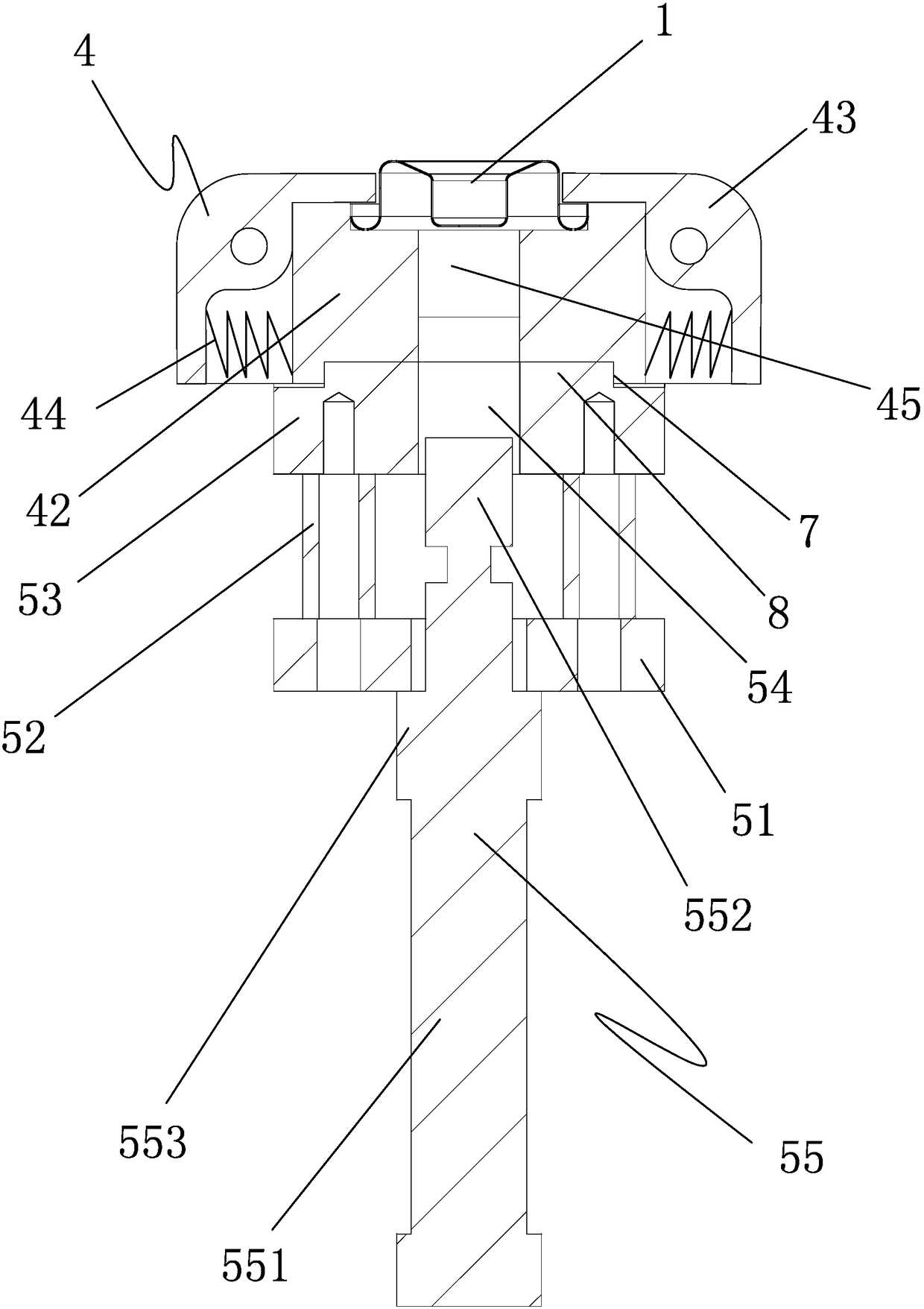

[0019] Such as Figures 1 to 3 A kind of rejecting device shown, comprises track seat 1, is provided with the track groove 3 that is used to place material 2 in described track seat 1, is provided with on described track seat 1 and can make material 2 break away from track groove 3 The loose-leaf mechanism 4 is provided with an ejecting mechanism 5 that can drive the loose-leaf mechanism 4 to open and eject the material 2 out of the track seat 1 under the loose-leaf mechanism 4 .

[0020] In the present invention, when the material passes through the track groove 3 and passes through the loose-leaf mechanism 4, if it is confirmed as an unqualified product by the previous process, it can be quickly ejected here, and the ejecting mechanism 5 moves upward to push the material, and the loose-leaf mechanism 4 overcomes the spring pressure and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com