A construction method for assembling trolley formwork with gradually changing section of tunnel arch wall lining

A trolley formwork and construction method technology, applied in tunnel lining, tunnel, shaft lining and other directions, can solve the problems of easy deformation of formwork, time-consuming and labor-intensive, and achieve the effect of ensuring clearance size, simple and convenient dismantling, and ensuring appearance quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

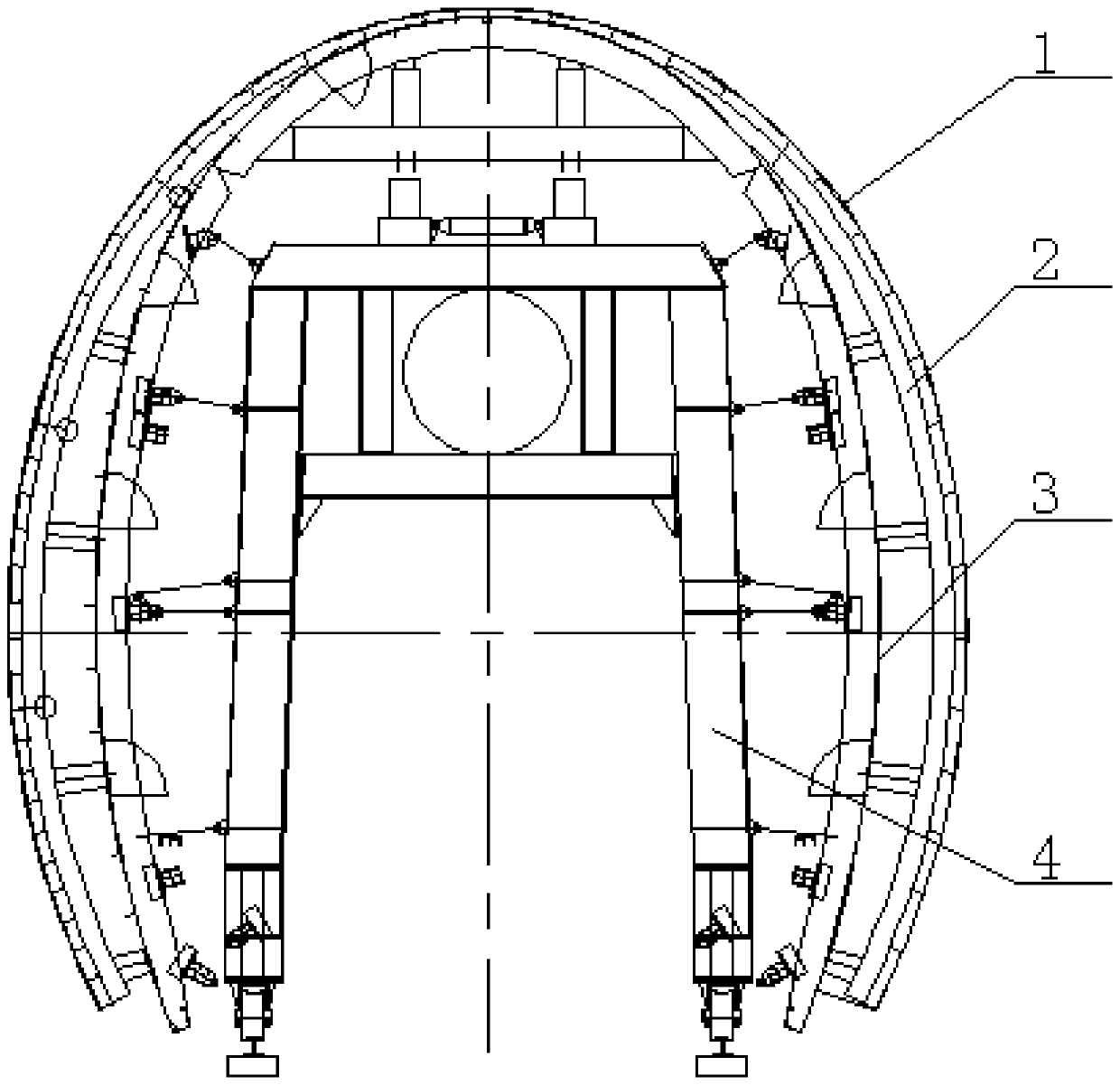

[0025] The trolley template, such as figure 1 As shown, including trolley 4, which is used as the main support of the trolley formwork, the original trolley formwork 3 is provided on the outside of the trolley 4, and a plurality of The formwork support 2 is assembled with a formwork 1, between the original trolley formwork 3 and the trolley 4, between the formwork support 2 and the original trolley formwork 3 and between the formwork support 2 and the trolley The templates 1 are fixed by bolts.

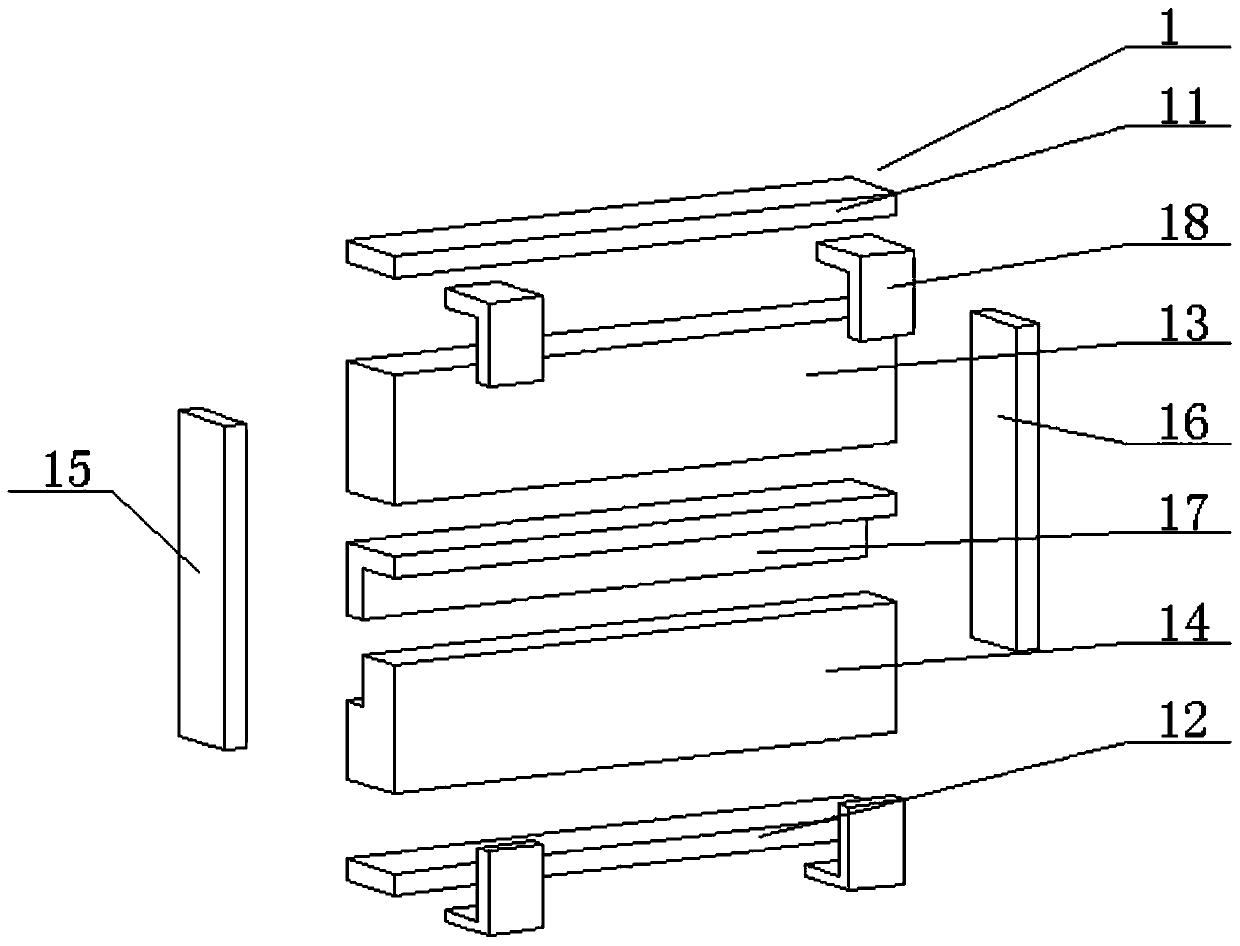

[0026] Further, the template 1 includes a frame composed of an upper connecting plate 11, a lower connecting plate 12, a front arch 15 and a rear arch 16, the upper edge of the upper connecting plate 11 and the upper panel 13 are formed by welding, so The lower connecting plate 12 and the lower edge of the lower panel 14 are formed by welding, and the front arch plate 15 and the rear arch plate 16 are respectively welded at the two side edges of the upper panel 13 and the lower panel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com