An automatic positioning device for riveting the intermediate joint of a rubber hose

A technology of automatic positioning and intermediate joints, which is applied in the field of mechanical devices, can solve problems such as time-consuming and labor-intensive, and achieve the effects of improving production efficiency, realizing automated and unmanned production, and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

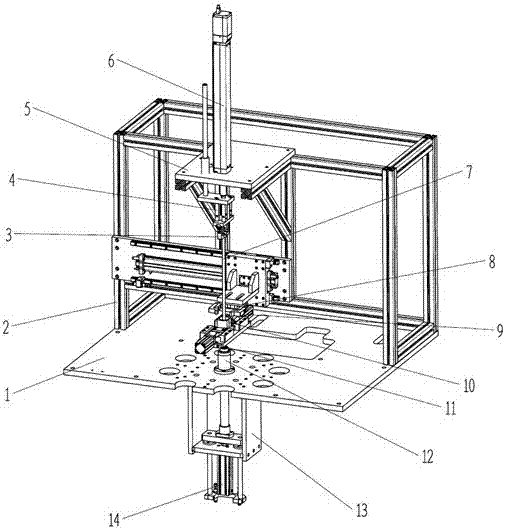

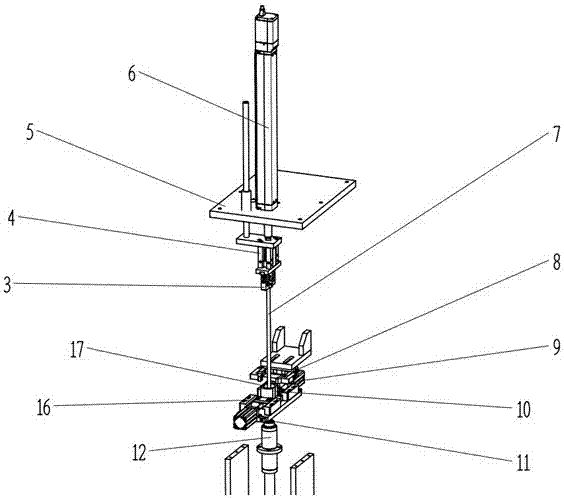

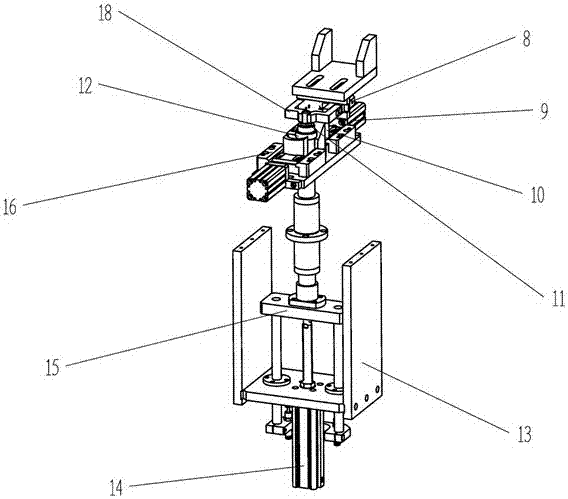

[0013] Such as Figure 1 to Figure 3 As shown, a rubber hose intermediate joint riveting automatic positioning device is characterized in that it includes a main board 1, a bracket 2 located above the main board 1, a joint cylinder fixing plate 13 located below the main board 1, and a 2 on the cylinder fixing plate 5, the cylinder fixing plate 5 is equipped with a rubber hose feeding electric cylinder 6, the piston rod of the rubber hose feeding electric cylinder 6 is connected to the rubber hose clamping claw cylinder 4, and the rubber hose clamping claw cylinder 4 is provided with a rubber hose clamping jaw 3 A joint support cylinder 14 is installed on the joint cylinder fixing plate 13, the piston rod of the joint support cylinder 14 passes through the main board 1 and its end is connected to the joint support block 12, and a guide slide i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com