Tractor front drive axle provided with cylindrical helix gear-type limited slip differential

A limited-slip differential, front drive axle technology, applied in the control device, transportation and packaging, vehicle components, etc., can solve the problems of front drive axle danger, tractor overturning, etc. Effects through abilities and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

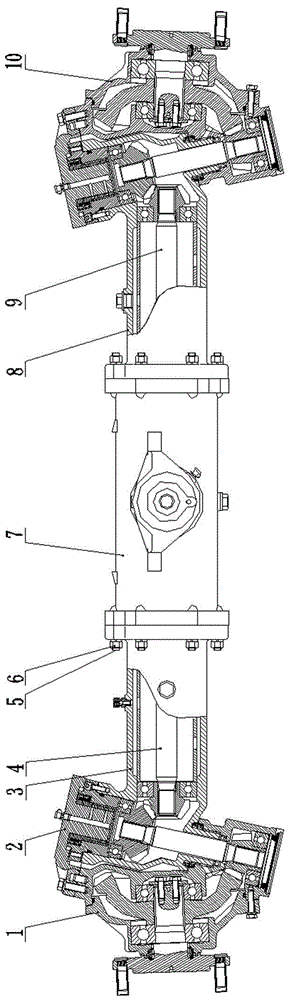

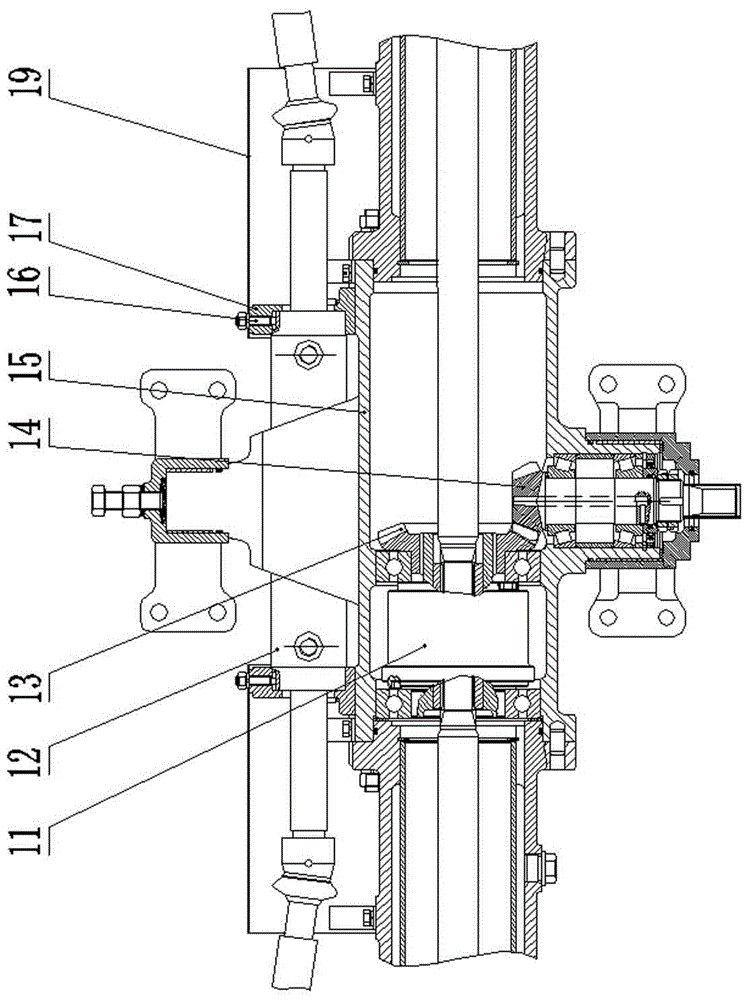

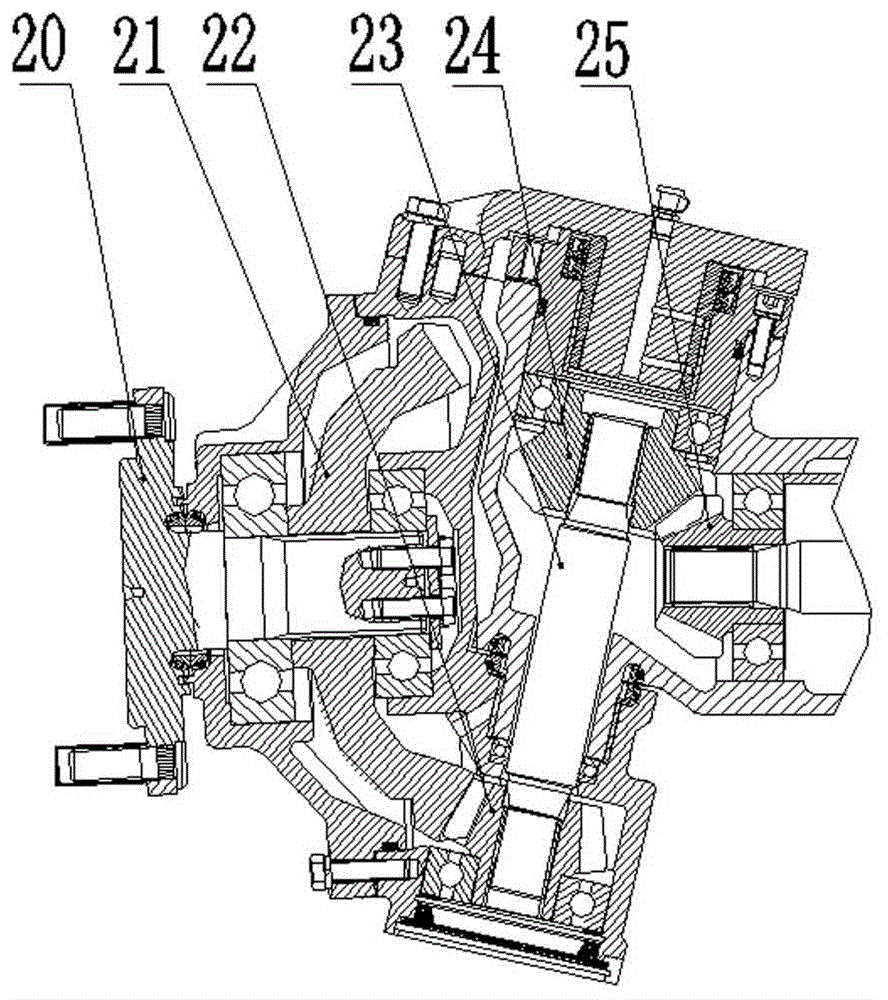

[0024] A tractor front drive axle with a cylindrical helical gear type limited-slip differential of the present invention, its structure includes a main reduction box assembly 7, a left half-shaft housing 3, a left end transmission box assembly 1, and a right half-shaft housing body 8 and right end transmission box assembly 10; the left end of the main reduction box assembly 7 is connected with the left half shaft housing 3, and the main reduction box assembly 7 is respectively connected with the left half shaft housing through studs 5 and nuts 6 3. The right half shaft housing 8 is installed and connected; the left half shaft housing 3 is installed with the left half shaft 4, and the left end of the left half shaft housing 3 is connected with the left end transmission box assembly 1 through the connecting cover 2; the main reduction box The right end of the assembly 7 is connected to the right half shaft housing 8, and the right half shaft 9 is installed in the right half shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com