Mini-tiller gear shifting transmission assembly and mini-tiller

A micro-tiller and assembly technology, applied in the field of micro-tillers, can solve problems such as potential safety hazards, increased reverse gear speed, and loss of the best time to get out of trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

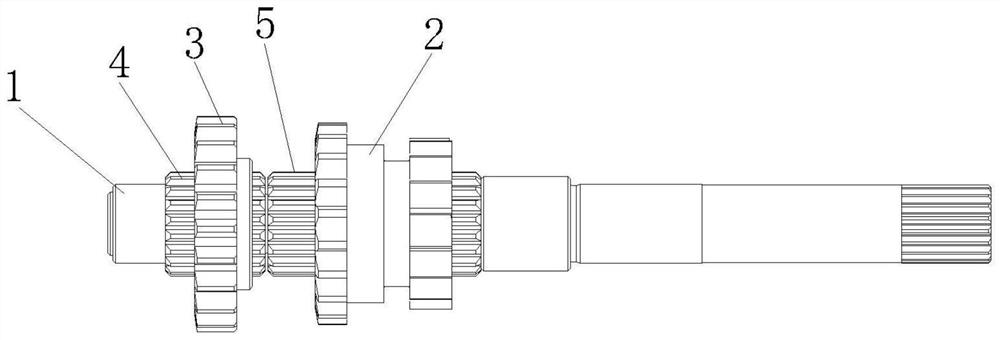

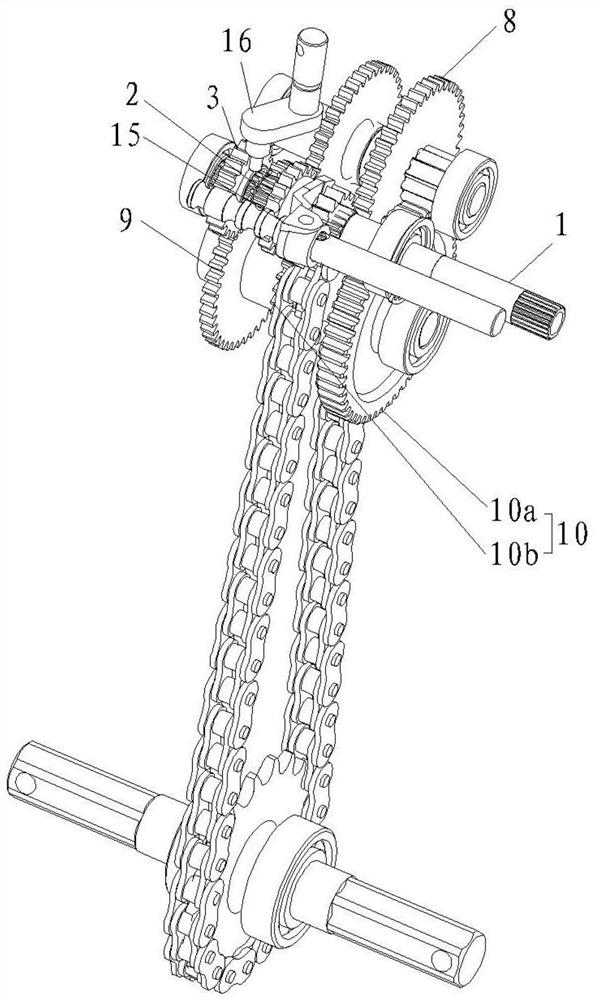

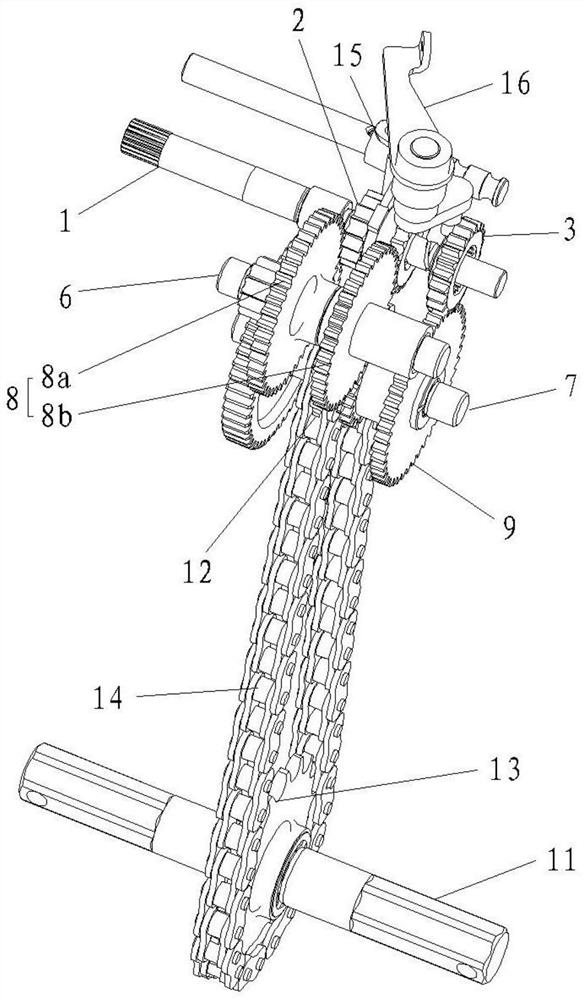

[0019] This embodiment provides a micro tillage machine replacement assembly, including a main shaft 1, a forward gear driving gear 2 and a reverse gear driving gear 3, the forward gear driving gear 2 is rotatably mounted on the main shaft, and the reverse gear driving gear 3 Installed on the main shaft in a transmission fit and axially slidable manner, the reverse driving gear 3 has at least two transmission states when sliding axially along the main shaft:

[0020] State 1: the reverse driving gear 3 is disconnected from the forward driving gear 2, and the reverse driving gear 3 is used to mesh with the reverse transmission structure to transmit power to the output shaft to drive the output shaft to reverse;

[0021] State 2: Reverse gear driving gear 3 is in transmission cooperation with forward gear driving gear 2, and the reverse gear driving gear is separated from the reverse gear transmission structure, and the power is transmitted to the output shaft through the forward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com