A gearbox tray

A gearbox and tray technology, applied in the field of gearboxes, can solve the problems that the gearbox disassembly can only be done manually, the gearbox does not have enough support, and the gearbox is damaged, so as to solve the problem of bumping or even falling to the ground with high reliability , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

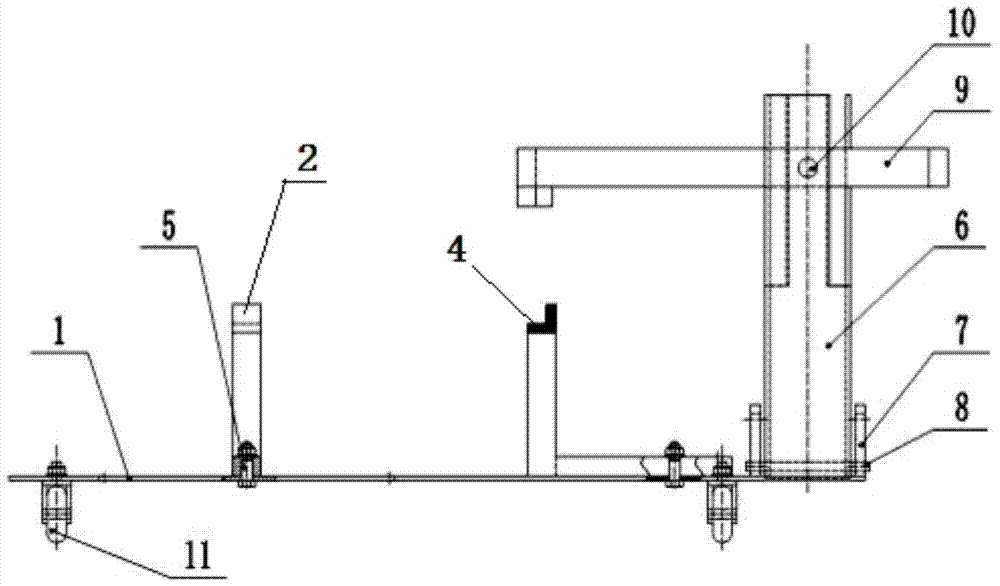

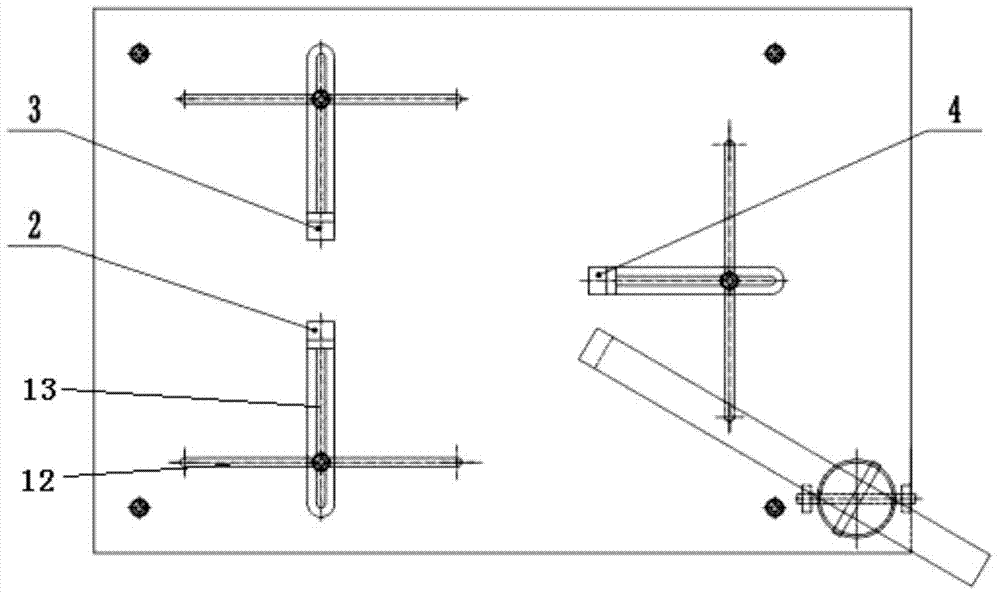

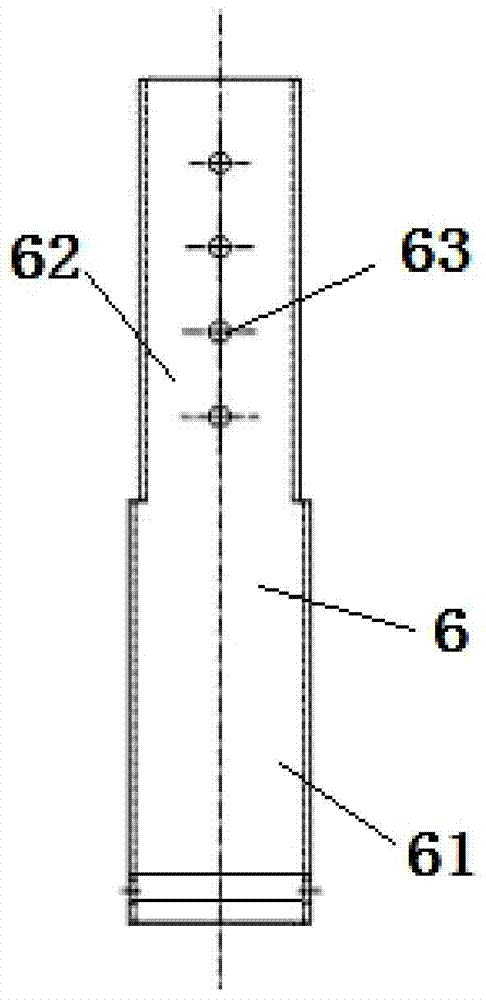

[0024] The gearbox tray of the present invention, such as figure 1 , 2 As shown, it includes the base plate 1 and the walking wheel 11 located at the lower end of the base plate 1. The base plate 1 is provided with a plurality of positioning blocks for positioning the gearbox and crimping and crimping devices on the top of the gearbox case cover. The positioning blocks are relative to the base plate. The position of 1 can be moved and adjusted, and the crimping device can be adjusted according to the height of the gearbox. The gearbox tray can be adjusted according to the size or height of the gearbox to be transported, and is suitable for the transportation of different types of gearboxes. It is convenient and quick to use and has good applicability.

[0025] An embodiment provided by the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com