Methods of welding thermoplastic composites and doped resins used therein

A technology of composite material and welding method, applied in the field of welding method and doped resin used therein, can solve the problems of inability to realize the welding of CFRTP components, and achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

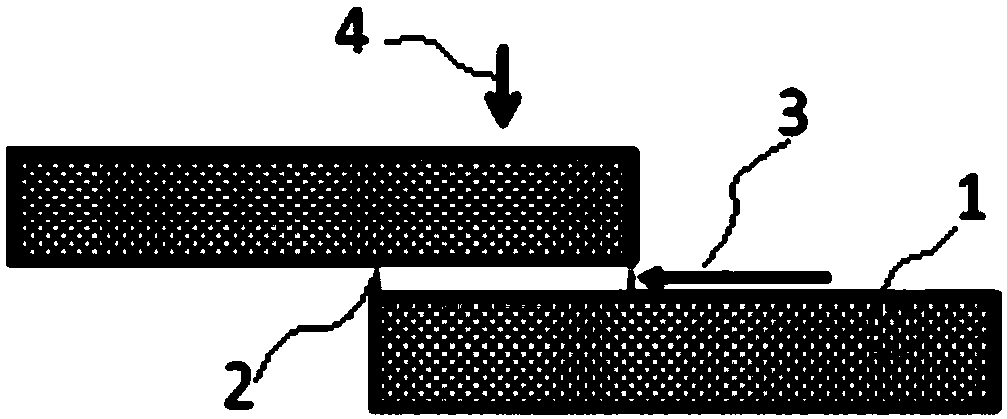

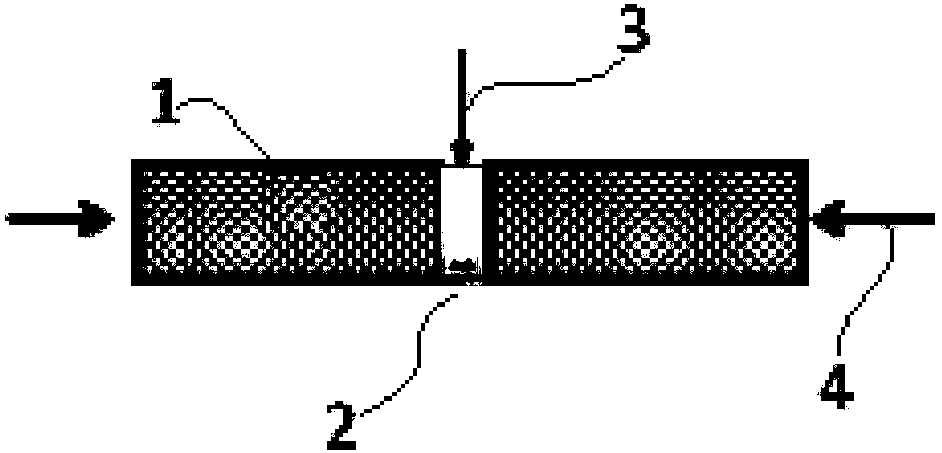

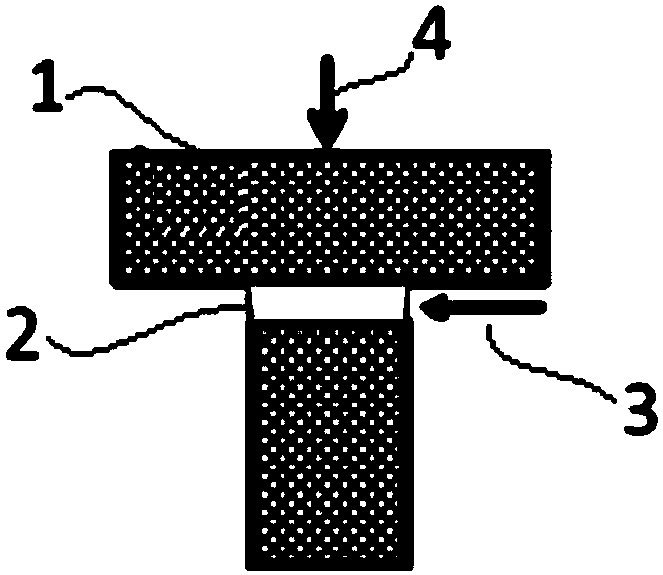

[0056] A welding method of thermoplastic composite material includes the following steps:

[0057] 1. Pre-treatment.

[0058] The welding surface of the doped resin and the carbon fiber thermoplastic composite member to be welded is cleaned with an organic solvent to remove stains.

[0059] 2. Material preparation.

[0060] The doped resin with a thickness of 0.2mm is placed between two carbon fiber thermoplastic composite materials to be welded, and the three are pressed together by the external force of a pneumatic device or a spring device.

[0061] The above-mentioned doping resin includes a matrix material and a doping material. The matrix material is a transparent thermoplastic resin (polyamide resin, PA), and the doping material is colored carbon black particles (8μm) that can absorb light energy and convert it into heat energy. , The volume percentage of the doping material in the doping resin is 0.05%.

[0062] 3. Welding.

[0063] Using a fiber laser with a wavelength of 1064nm...

Embodiment 2

[0067] A welding method of thermoplastic composite material includes the following steps:

[0068] 1. Pre-treatment.

[0069] The welding surface of the doped resin and the carbon fiber thermoplastic composite member to be welded is cleaned with an organic solvent to remove stains.

[0070] 2. Material preparation.

[0071] A doped resin with a thickness of 0.5mm is placed between two carbon fiber thermoplastic composite materials to be welded, and the three are pressed together by external force such as pneumatic devices or spring devices.

[0072] The above-mentioned doping resin includes a matrix material and a doping material. The matrix material is a transparent thermoplastic resin (polyethylene resin, PE), and the doping material is colored indium tin oxide particles (5 μm) that can absorb light energy and convert it into heat energy. ), the volume percentage of the doping material in the doping resin is 0.06%.

[0073] 3. Welding.

[0074] Using a fiber laser with a wavelength of ...

Embodiment 3

[0078] A welding method of thermoplastic composite material includes the following steps:

[0079] 1. Pre-treatment.

[0080] The welding surface of the doped resin and the carbon fiber thermoplastic composite material component to be welded is cleaned with an organic solvent to remove stains.

[0081] 2. Material preparation.

[0082] The doped resin with a thickness of 1mm is placed between two carbon fiber thermoplastic composite materials to be welded, and the three are pressed together by external force such as pneumatic devices or spring devices.

[0083] The above-mentioned doped resin includes a base material and a dopant material. The base material is a transparent thermoplastic resin (polymethylmethacrylate resin, PMMA), and the dopant material is a colored copper oxide that can absorb light energy and convert it into heat. Particles (10 μm), the volume percentage of the doping material in the doping resin is 0.08%.

[0084] 3. Welding.

[0085] Using a fiber laser with a wavel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com