Rotating pyrolysis furnace

A technology of rotary pyrolysis and pyrolysis furnace, which is applied in the field of pyrolysis furnace, which can solve the problems of large spring size, poor sealing performance, inconvenient loading and unloading, etc., to reduce the leakage rate, simple and convenient structure, and convenient adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

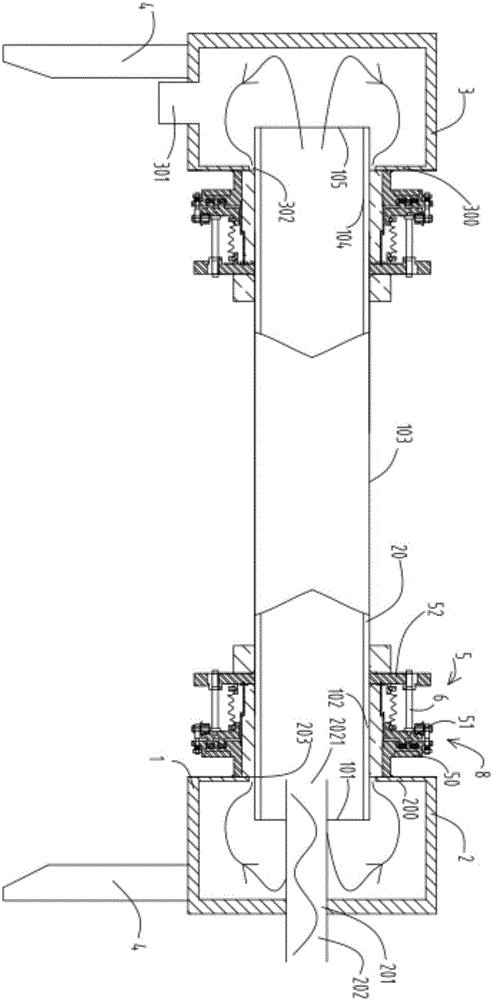

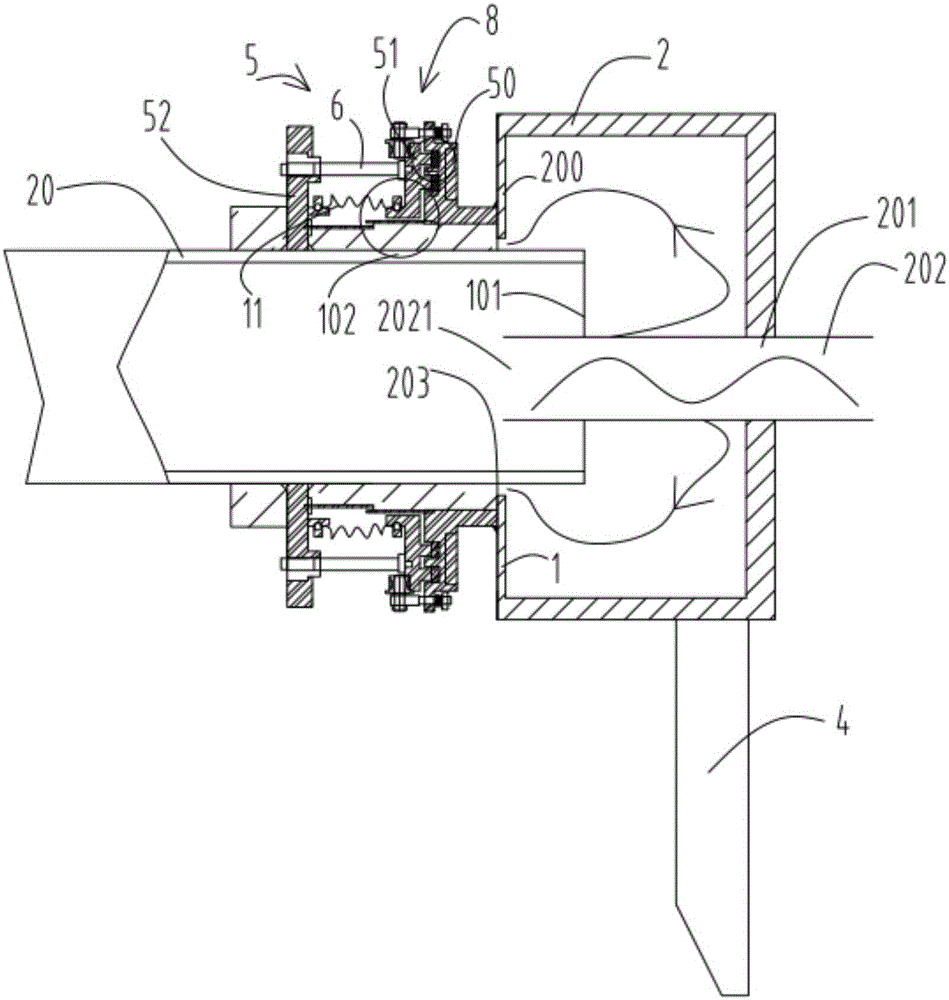

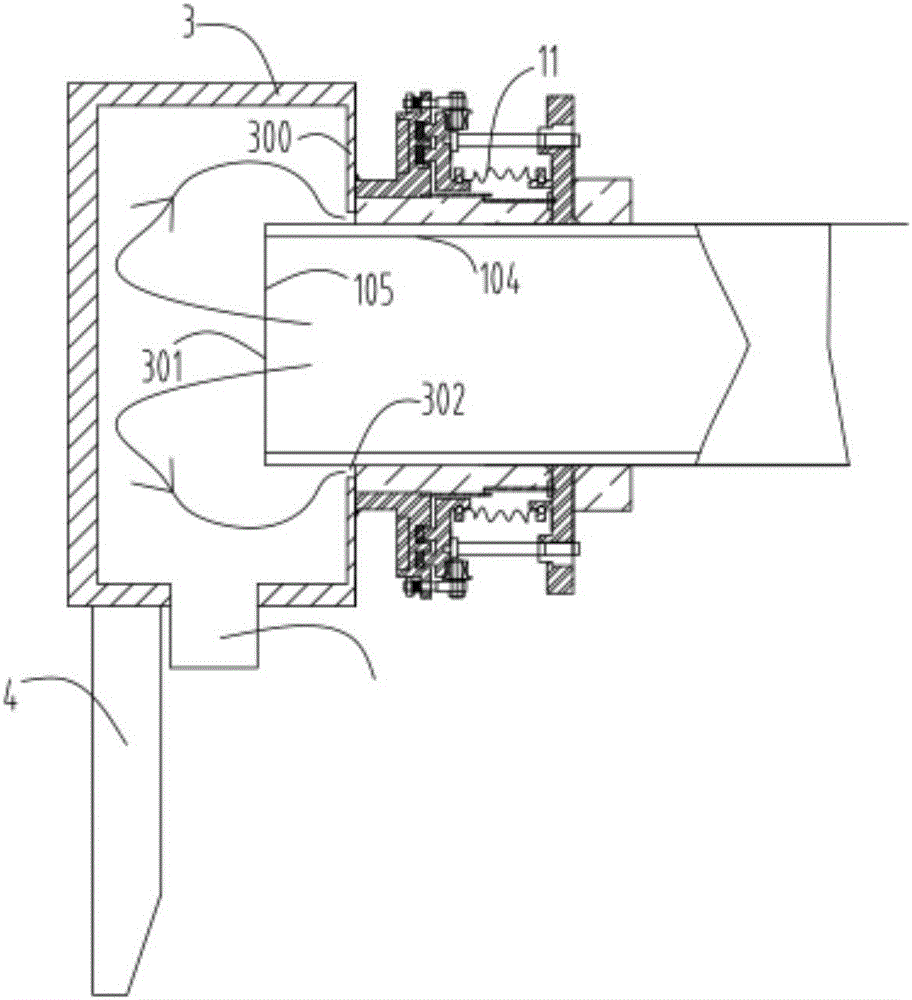

[0041] figure 1 It is a schematic diagram of the overall structure of Embodiment 1 of a rotary pyrolysis furnace; figure 2 It is a schematic structural view of the feed bin part in the rotary pyrolysis furnace according to Embodiment 1; image 3 It is a structural schematic diagram of the discharge bin part in the rotary pyrolysis furnace according to Embodiment 1; Figure 4 It is a schematic diagram of the local structure of the channel in the sealing mechanism for preventing gas exchange according to the first embodiment; Figure 5 It is a schematic diagram of the structure of the joint in the sealing mechanism for preventing gas exchange according to Embodiment 1; Figure 6 It is a schematic diagram of the structure of the guide wheel device defined in the sealing mechanism for preventing gas exchange according to the first embodiment; Figure 7 It is a schematic diagram of the structure of the gas flow channel opening in the sealing mechanism for preventing gas exchang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com