Accurate positioning device for hoisting of prefabricated part

A technology for precise positioning and prefabrication of components, which is applied in building construction, construction, and building materials processing. , to achieve the effect of reliable construction quality, simple structure and improved installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following is a specific embodiment of the present invention, and the present invention will be further described in conjunction with the accompanying drawings.

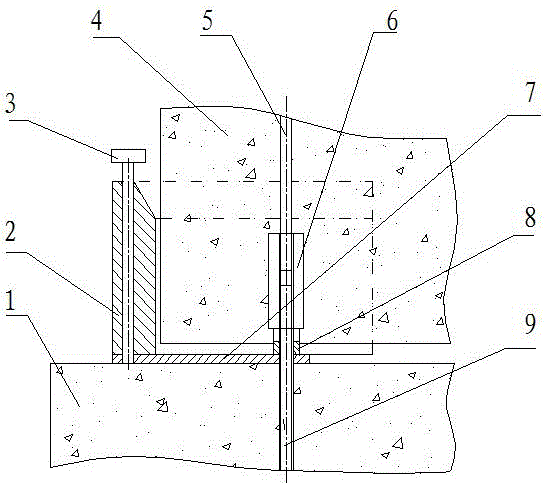

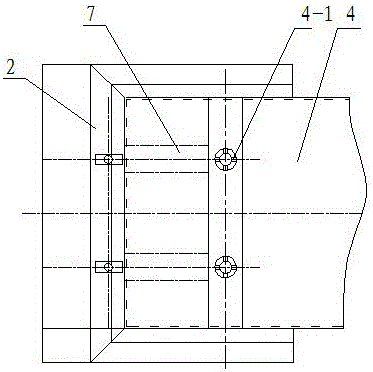

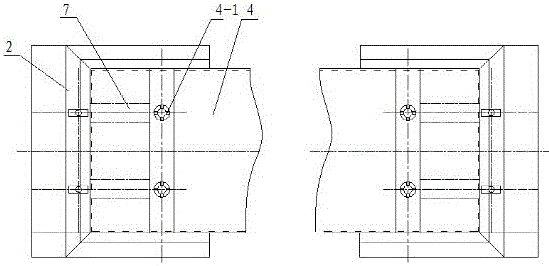

[0020] Such as Figure 1 to Figure 3 As shown, a prefabricated component hoisting and precise positioning device includes a U-shaped vertical plate 2 placed on the lower floor 1. The U-shaped vertical plate 2 is formed by connecting three straight plates, and the inner edge of the upper end has a bevel . The bottom of the U-shaped vertical plate 2 is fixed with a horizontal positioning base plate 7, and the positioning base plate 7 is attached to the lower floor 1, and its quantity is consistent with the quantity of the pre-embedded steel bars 9 on the lower floor 1. The positioning base plate 7 is a strip-shaped plate, and one end of the positioning base plate 7 has a positioning hole I cooperating with the embedded steel bar 9 of the lower floor 1, and the other end has a positioning hole II. The positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com