A hydraulic state detection and maintenance vehicle

A technology for condition detection and maintenance of vehicles, which is applied in the testing of fluid pressure actuation systems, fluid pressure actuation devices, mechanical equipment, etc. The effect of easy secondary pollution, prevention of secondary pollution, and simple and convenient detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

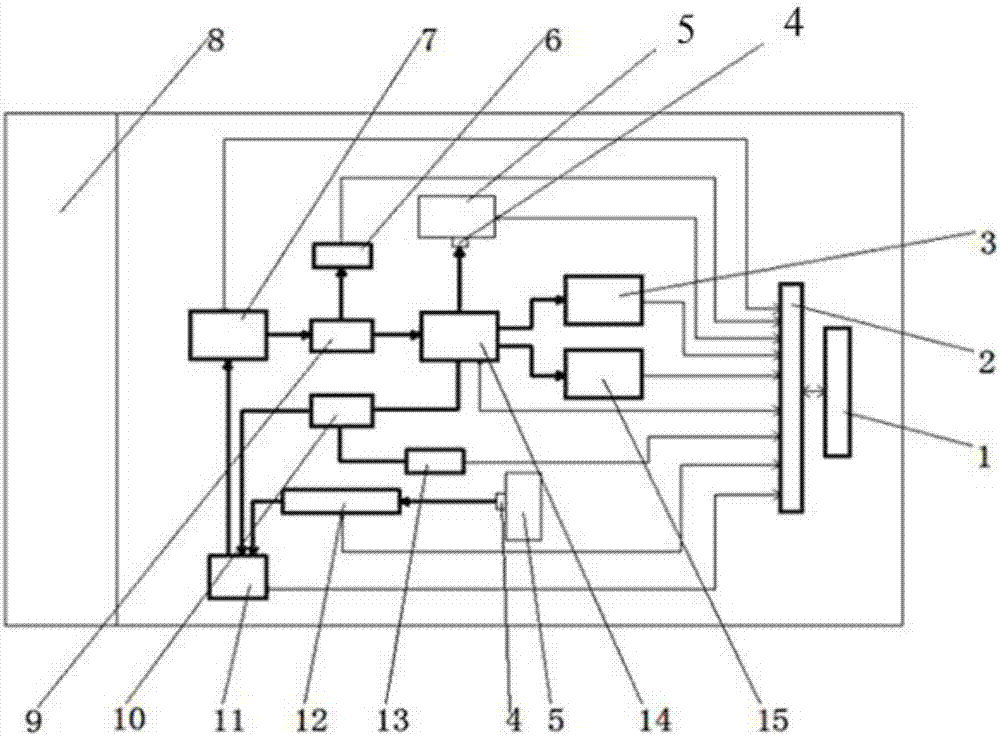

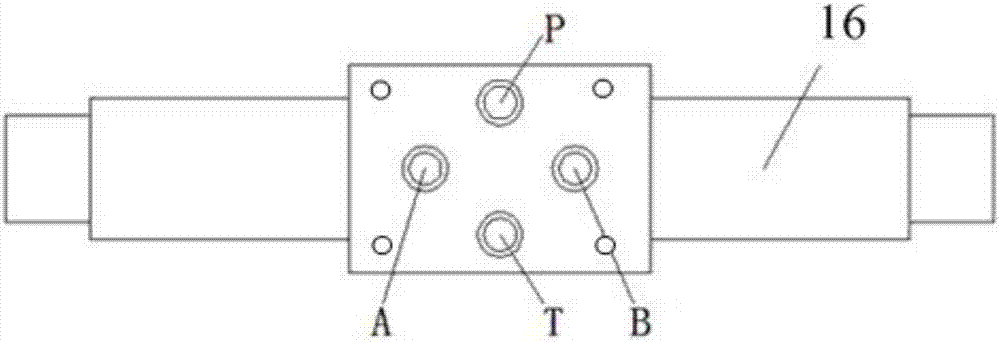

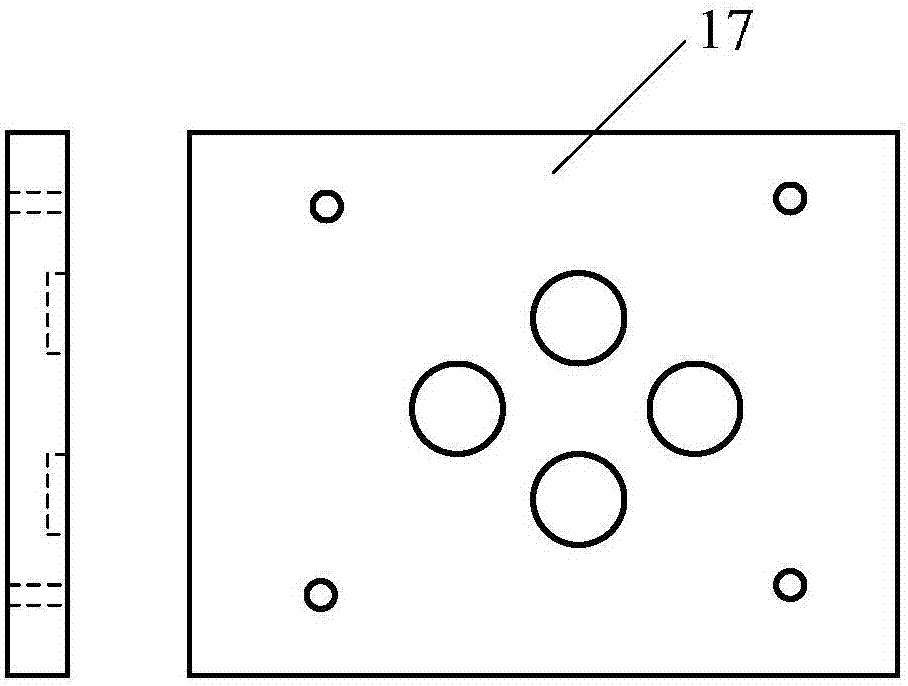

[0020] In the present invention figure 1In the schematic diagram, the van is a commercially available small van, and side doors are arranged on the left and right side walls of the box body 8, and the side doors are connected to the side walls of the box body by hinges. The back of the car body is provided with a back door, and the back door and the back of the car body are hinged. In the compartment of the van, place a pollutant detection module 12, a fuel tank 11, a variable constant flow module 7, a first flow meter 9, a first sensor 6, a hydraulic control valve module 14, a temperature sensor 3, a pressure sensor 15, The second flow meter 10 , the second sensor 13 , the variable constant flow module, the data input and output module 2 and the control module 1 . The total pressure measuring joint 4 of the hydraulic system to be tested is connected to the input end of the pollutant detection module, the output end of the pollutant detection module is connected to an input e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com