Direct cooling refrigerator fan control method system and refrigerator

A direct-cooling refrigerator and fan technology, applied in coolers, household refrigerators, household refrigeration devices, etc., can solve the problems of poor consistency in the operation of the whole machine, poor consistency of magnetic switches, etc., and achieve low power consumption and freshness preservation speed Fast, good temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

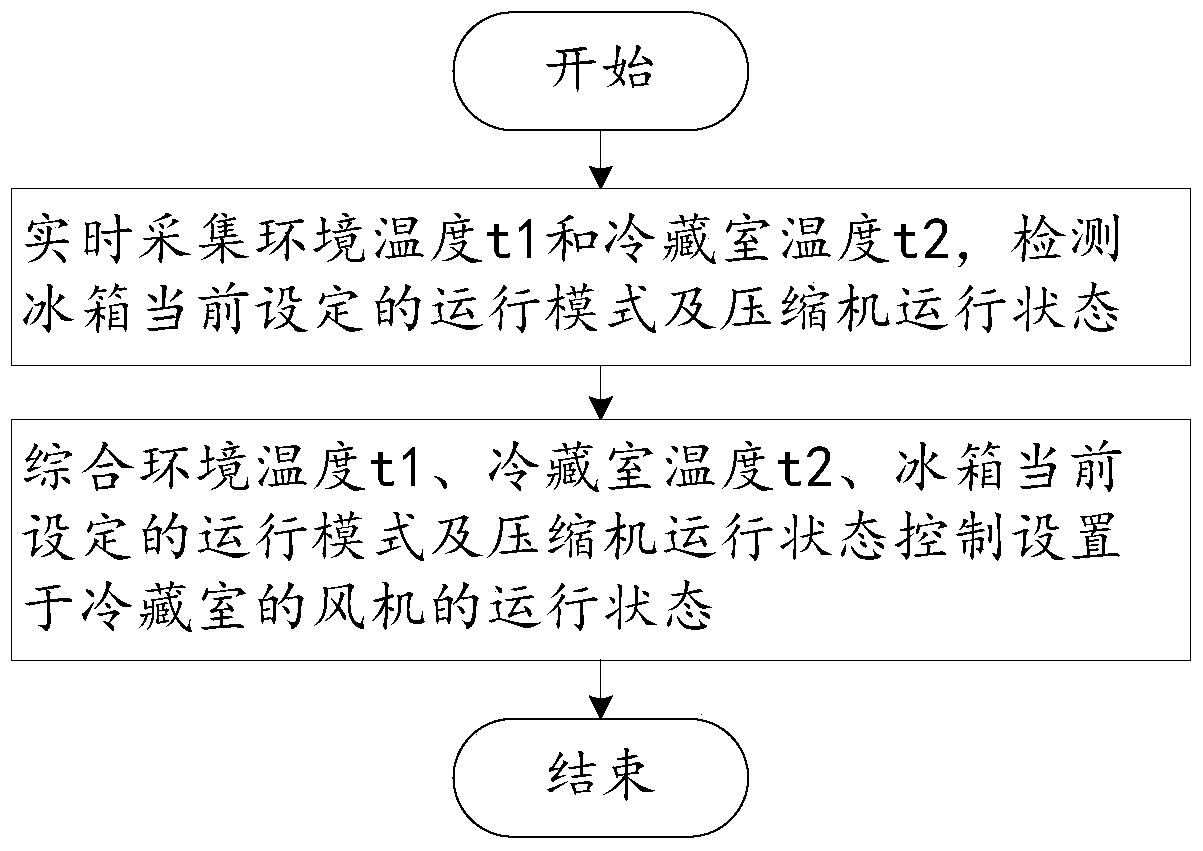

[0023] Example 1. Such as figure 1 As shown, a direct cooling refrigerator fan operation control method, the direct cooling refrigerator is provided with a fan in the refrigerating room, comprising the following steps:

[0024] S1, collect the ambient temperature t1 and the refrigerator temperature t2 in real time, and detect the currently set operating mode of the refrigerator and the operating status of the compressor;

[0025] S2. Control the operating state of the fan in the refrigerating chamber according to the ambient temperature t1, the refrigerating chamber temperature t2, the currently set operating mode of the refrigerator, and the operating state of the compressor.

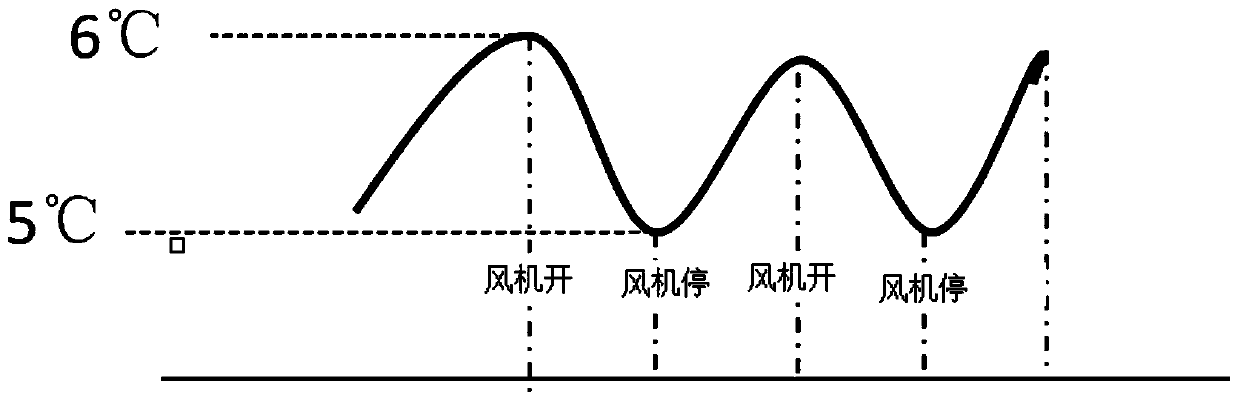

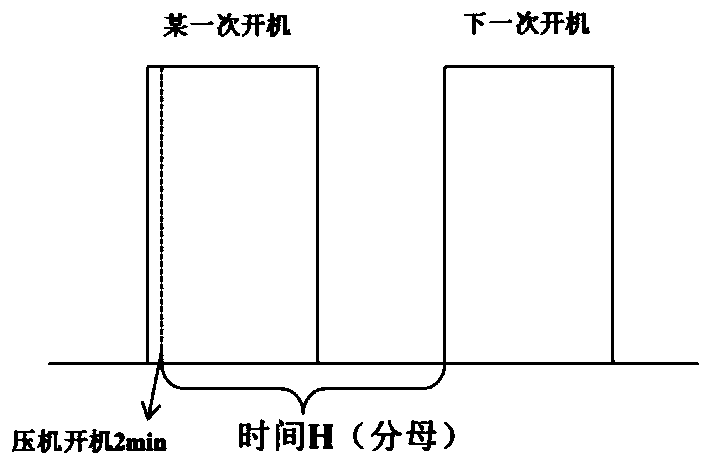

[0026] In the present invention, a fan is installed in the refrigerating chamber of a refrigerator with a direct cooling structure. The operation mode of the fan is affected by the ambient temperature, the temperature of the refrigerating room, the different gear functions set by the user, and the ope...

Embodiment 2

[0049] Example 2, such as Figure 5 As shown, a direct cooling refrigerator fan control system, the direct cooling refrigerator is provided with a fan in the refrigerating room, including: a data acquisition module, used to collect the ambient temperature t1 and the refrigerating room temperature t2 in real time, and detect the currently set operation of the refrigerator mode and compressor running state; the control module is used to control the running state of the fan in the refrigerating chamber according to the ambient temperature t1, the refrigerating chamber temperature t2, the currently set operating mode of the refrigerator, and the operating state of the compressor.

[0050] The present invention controls the operating rate of the refrigerating room spoiler fan according to the ambient temperature, refrigerating temperature, different gears and functions set by the user, and the start and stop of the compressor, so as to realize the adjustable evaporation capacity of ...

Embodiment 3

[0056] Example 3, such as Figure 6 As shown, a refrigerator includes a refrigerating chamber 1 and a freezing chamber 2, and a fan 5 is arranged in the refrigerating chamber 1, and also includes the direct cooling refrigerator fan control system described in Embodiment 2, and the direct cooling refrigerator fan control system The data acquisition module includes an ambient temperature sensor 3 and a refrigerating room temperature sensor 4, which are used to collect the ambient temperature t1 and the refrigerating room temperature t2 respectively. The structure of the refrigerator adopts the structural design of a direct cooling refrigerator, and the refrigeration system is matched according to the condition that the fan operation rate is 100%. The volume of the refrigerating chamber of the refrigerator is greater than or equal to 100L. Both the refrigerating chamber and the freezing chamber of the refrigerator are provided with evaporators, and the sizes of the evaporators i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com