Packaging structure of lithium ion battery, and packaging method and formation method for packaging structure

A lithium-ion battery and packaging structure technology, which is applied in the direction of secondary batteries, structural parts, electrochemical generators, etc., can solve problems such as poor paths, gas, and unclean electrolyte discharge, and achieve material cost savings and energy savings. The use of, is conducive to the effect of protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

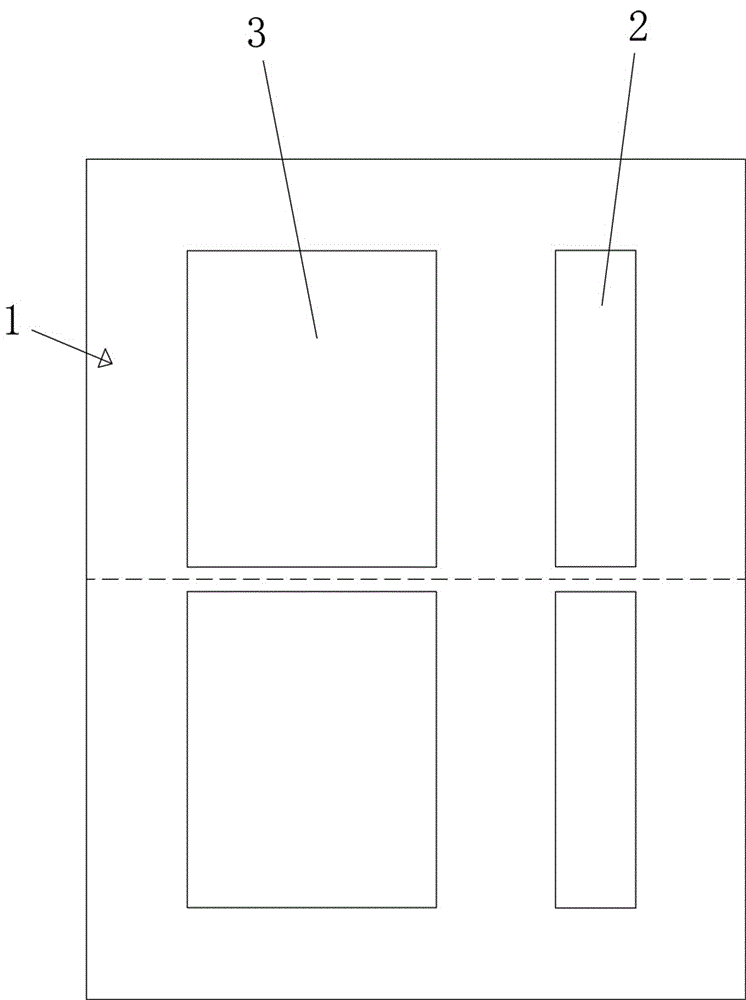

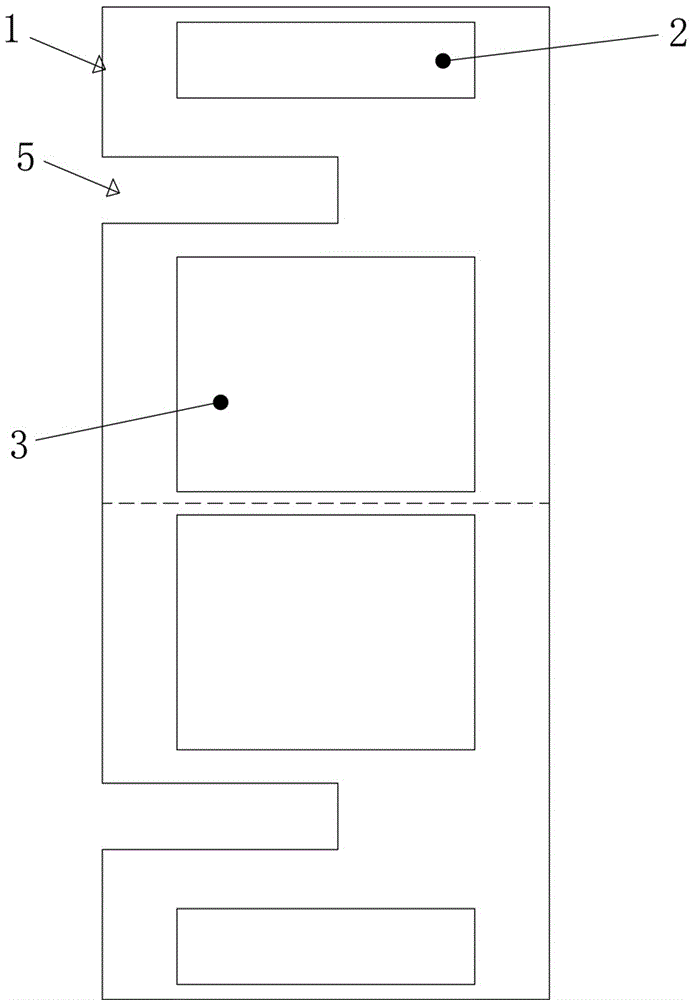

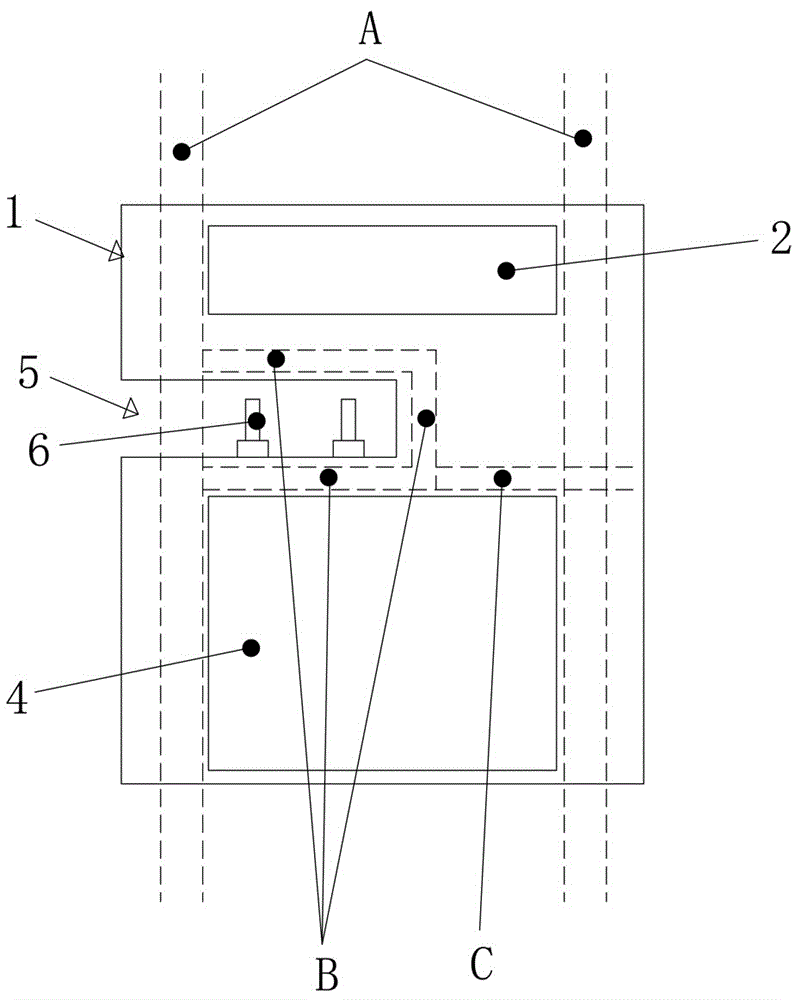

[0019] like figure 2 , 3 As shown, a packaging structure of a lithium-ion battery includes an aluminum-plastic film, and the aluminum-plastic film is provided with an air bag and a cell placement groove, along the vertical line of the double-fold line of the aluminum-plastic film from the double-fold line to the two sides of the aluminum-plastic film. The cell placement slot and the air bag are arranged symmetrically at the end in turn, and the aluminum-plastic film between the cell placement slot and the air bag is provided with a space-avoiding gap for accommodating tabs. Specifically, for batteries of the same size, the size of the original aluminum-plastic film is 168 mm in length and 107 mm in width, while the size of the aluminum-plastic film applied in the present invention is 240 mm in length and 73 mm in width, which is smaller than the occupied ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com