Energy-saving power strip

A plug-in board and circuit board technology, applied in the installation of electrical components, coupling devices, connecting parts, etc., can solve the problems of waste, power consumption and other problems, and achieve the effect of reducing electricity loss and increasing safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

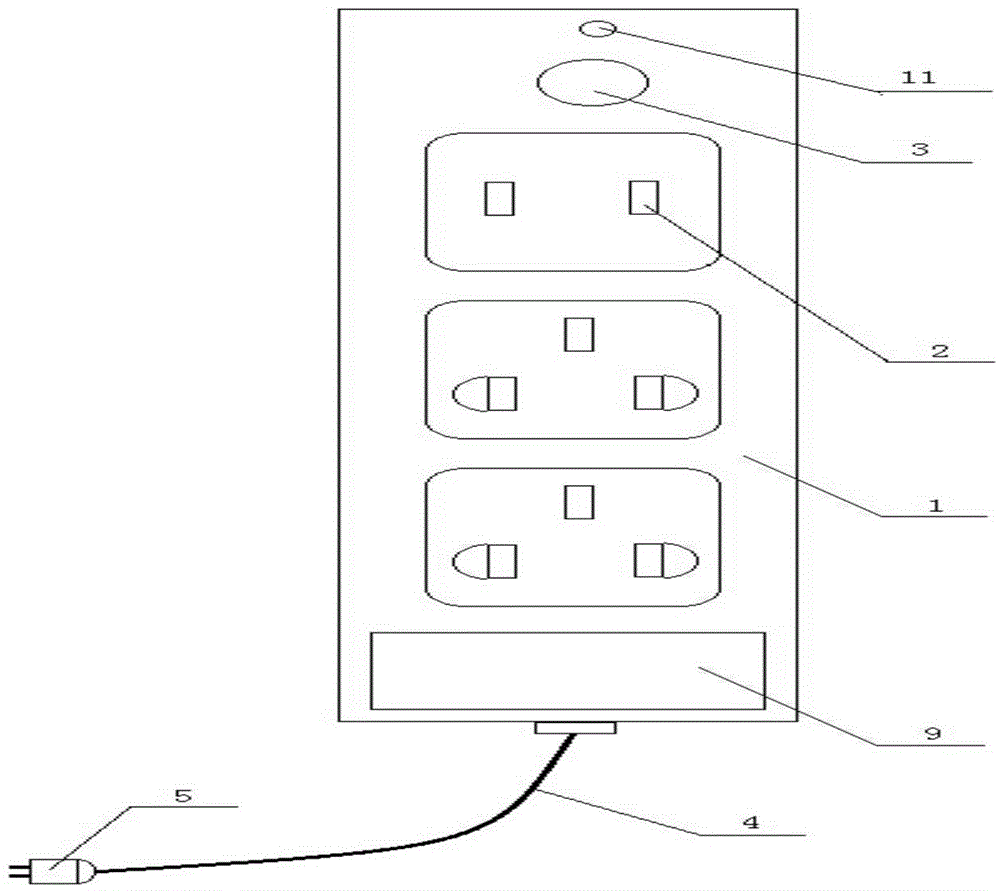

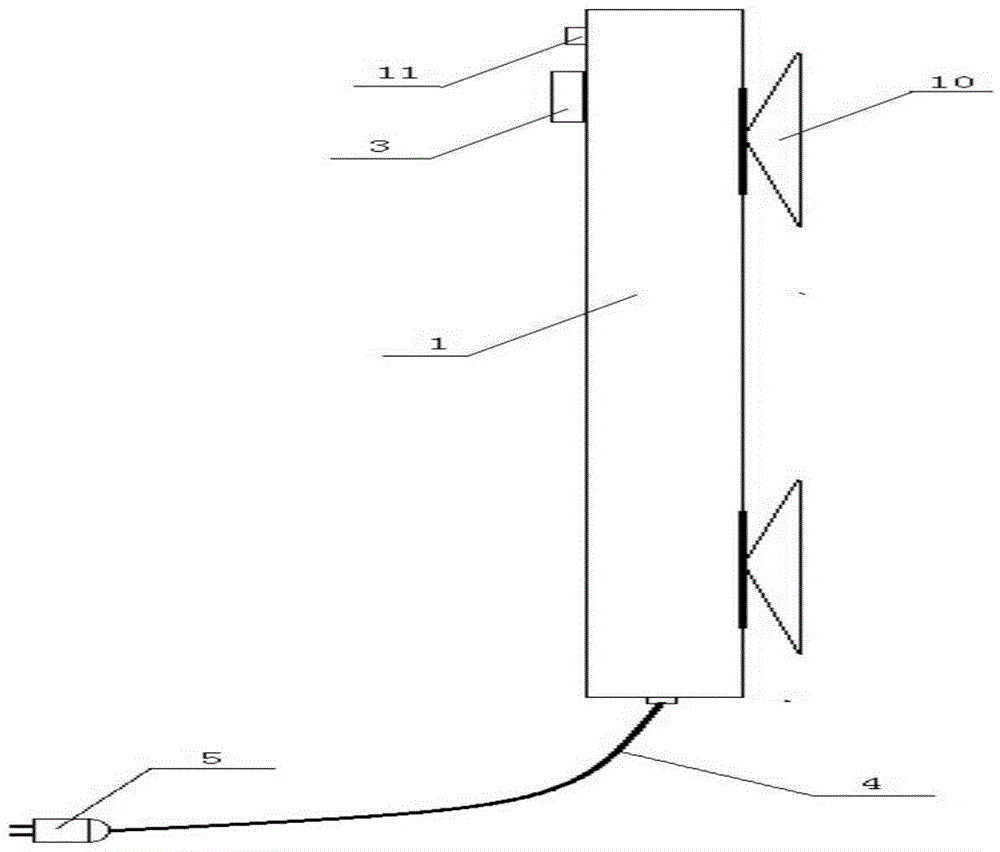

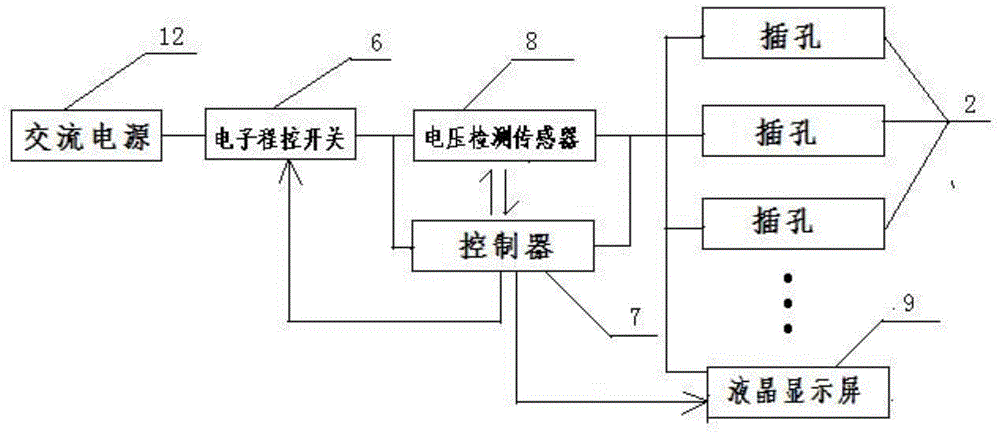

[0022] Such as figure 1 , figure 2 and image 3 The shown energy-saving plug-in board includes a plug-in board body 1, and the plug-in board body 1 is provided with a jack 2, a manual switch 3 for opening or closing the working state of the plug-in board, and a An indicator light 11 for the working state of the power strip, the power strip body 1 is connected to the power plug 5 through the connection line 4, a circuit board is arranged inside the power strip body 1, and an electronic program-controlled switch is integrated on the circuit board 6. The controller 7 and the voltage detection sensor 8 for detecting the voltage signal in the jack 2, the electronic program-controlled switch 6 is connected in series in the circuit where the AC power supply 12 supplies power to the jack 2, the input terminal of the controller 7 is connected to the The voltage detection sensor 8 is electrically connected, the output terminal of the controller 7 is electrically connected to the elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com