Telescopic gear type residual film picking and recycling machine

A technology of residual film picking and recycling machine, which is applied in the field of traction frames, can solve the problems of large tractor resistance, lifting of agricultural machinery that cannot be hung behind, and self-heavy, etc., to achieve high picking recovery rate, stable work, and good picking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

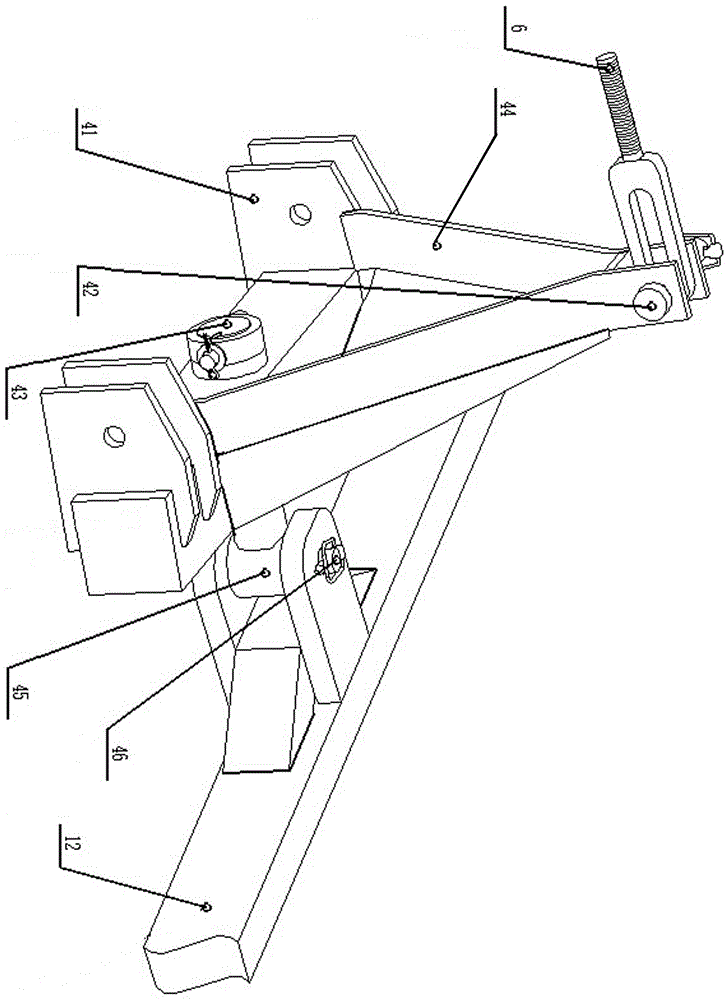

[0019] Such as figure 1 As shown, a traction frame for preventing the towed agricultural machinery from going too deep into the ground adopts three-point suspension and includes a triangular frame body 44. There are two connecting seats 41 at the lower part of the triangular frame body 44, and there are connection points at the top. The triangular frame body The center of the crossbeam at the bottom of the body 44 is connected with a rotating shaft 43, which can realize the non-synchronous rotation of the tractor and the pulled agricultural machinery (the contact surface of the ground wheel of the implement and the surface of the tractor wheel may not be on the same surface), and reduce the torsional force between the two. The rear end of the rotating shaft 43 is fixed with a vertical connecting rotating shaft 45, and the connecting rotating shaft 45 is hinged with the frame 12 of the agricultural machine to be pulled by the pin 46, so that the tractor for pulling the implement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com