Cigarette production process stability monitoring method

A technology of production process and stability, applied in the fields of tobacco, cigarette manufacturing, application, etc., can solve problems such as narrow quantification level, and achieve the effect of improving cigarette production and improving product quality stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

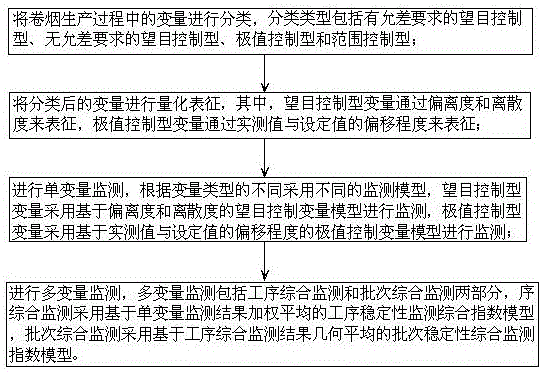

[0027] Such as figure 1 Shown, the cigarette production process stability monitoring method of the present invention, comprises the following steps successively:

[0028] 1. Classify the variables (including control parameters and quality indicators) in the cigarette production process. The classification types include Wangmu control type with tolerance requirements, Wangmu control type without tolerance requirements, extreme value control type and range control type;

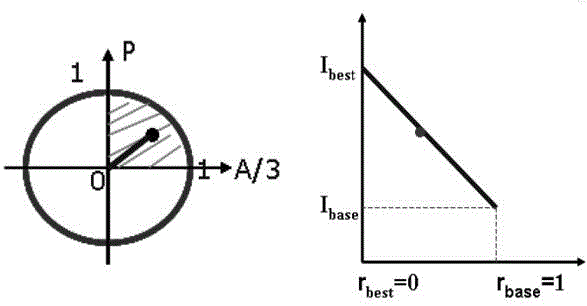

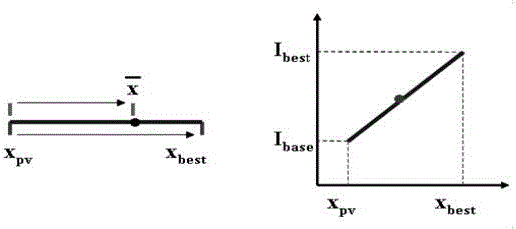

[0029] The eye control type includes two types: the eye control type with tolerance requirements and the eye control type without tolerance requirements: the eye control type with tolerance requirements, such as cylinder wall temperature, material moisture, cigarette suction resistance, etc. ; The eye control type without tolerance requirements, such as material flow, feeding ratio, etc., but it can be converted into fluctuations and precision to control or increase the control limit, and there is another type...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com