Smoke purifying method and smoke purifying equipment

A flue gas purification and flue gas technology, applied in the field of flue gas purification, can solve problems such as environmental pollution and flue gas pollution, and achieve the effects of low purification cost, strong adaptability and good flue gas purification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

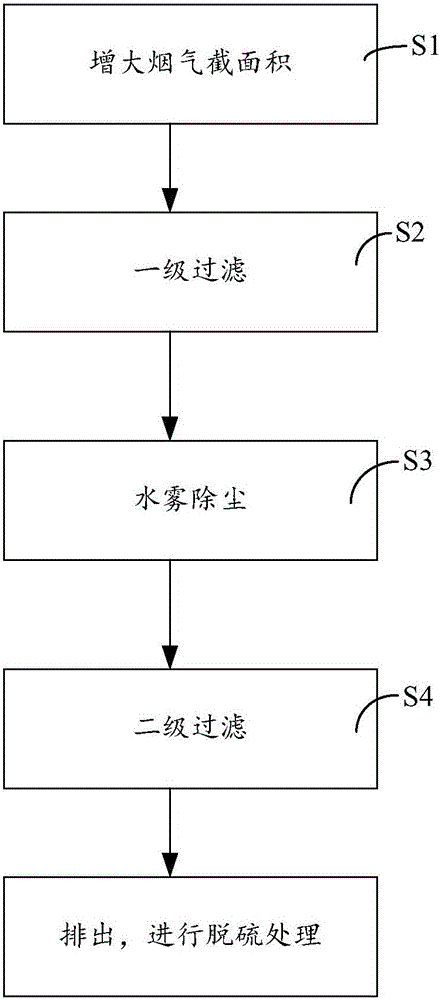

[0018] see figure 1 , the flue gas purification method comprises the following steps:

[0019] Step S1, increasing the cross-sectional area of the flue gas, reducing the flow velocity of the flue gas, and part of the gas and dust are naturally separated;

[0020] Step S2, primary filtering, performing primary filtering of the flue gas through the smoke filter, so as to separate the gas and smoke in the flue gas;

[0021] Step S3, water mist dedusting, spraying water mist to the flue gas, when the flue gas passes through the sprayed water mist, the dust in the flue gas will be completely purified;

[0022] Step S4, secondary filtration, the purified flue gas passes through the filter for secondary purification.

[0023] During the primary and secondary filtration of flue gas, the dust filter screen used is made of asbestos cloth and steel filter screen, and the steel filter screen is wrapped with asbestos cloth. After the flue gas passes through the secondary filtration, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com